Automatic plant mashing device for preparing plant preservatives

A plant preservative and plant technology, applied in the fields of grain processing, chemical instruments and methods, filtration and separation, etc., can solve the problems of time-consuming and laborious juice collection, waste of plant juice, difficulties, etc., to achieve sufficient juice collection, increase linkage, reduce wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

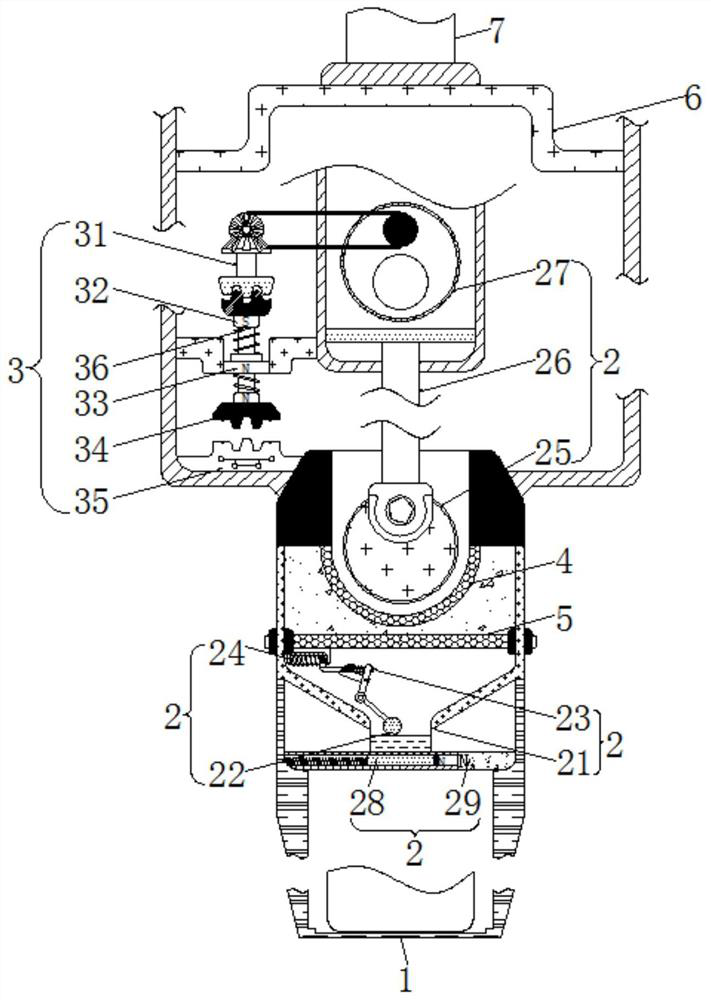

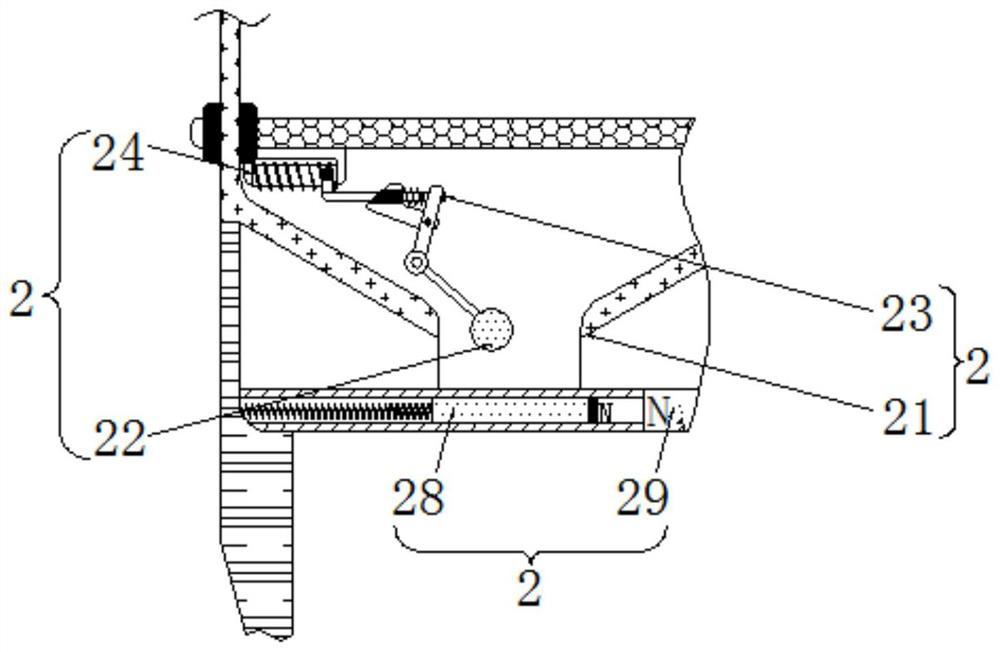

[0024] see Figure 1-2 , an automatic plant mashing device for preparing a plant preservative, comprising a juice outlet mechanism 2, the juice outlet mechanism 2 includes a mash juice cylinder 21, the bottom of the mash juice cylinder 21 is provided with an opening, and the size of the opening is compatible with the size of the baffle plate 28 At the same time, the baffle plate 28 will generate magnetism after being energized. At the same time, the magnetism is the same as the magnetic pole of the first fixed magnet 29. The baffle plate 28 is used to control the opening and closing of the pounding juice cylinder 21, so that the juice after pounding medicine can be automatically moved along the opening. Store, utilize first fixed magnet 29 to control the opening and closing of baffle plate 28 simultaneously, the inside of mashing juice tube 21 is movably connected with air bag 22, is provided with connecting rod between air bag 22 and push plate 23, and the surface of this conn...

Embodiment 2

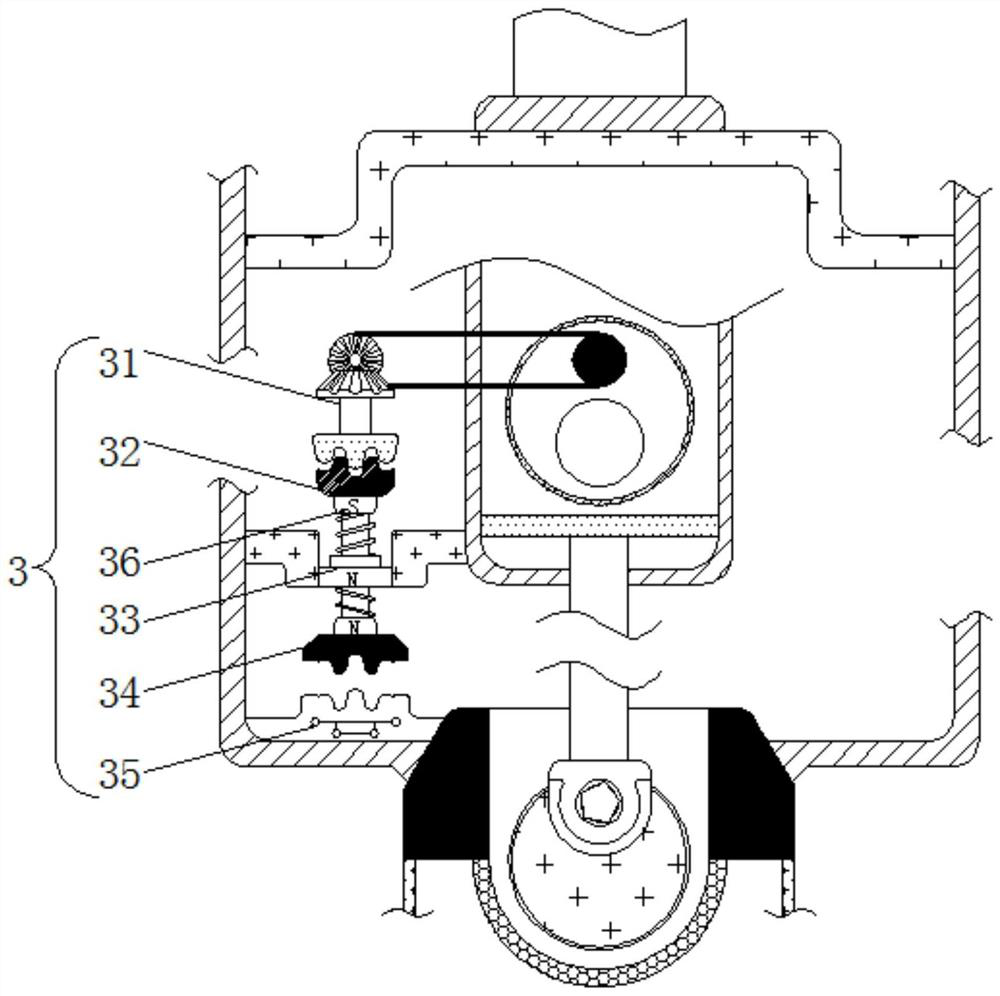

[0027] see figure 1 and image 3 , an automatic plant crushing device for preparing plant preservatives, and also includes a control mechanism 3, a rotating shaft 31 is connected to the left side of the juice outlet mechanism 2, and a limit roller 32 is sleeved under the rotating shaft 31, and the surface of the limit roller 32 is opened. There is a protrusion that is compatible with the internal size of the rotating shaft 31, and the inside of the limiting roller 32 is provided with a groove. When clamping, it drives the rotation of the rotating shaft 31. At the same time, a bevel gear and a runner are arranged on the top of the rotating shaft 31. The runner is connected with the limit disc 27 through a belt, which drives the limit disc 27 to rotate intermittently, and the limit roller 32 After energization, it also has magnetism, and the magnetism is opposite to the magnetic pole of the second fixed magnet 33. At the same time, the magnetism generated by the plug-in plate 3...

Embodiment 3

[0030] see Figure 1-3, an automatic plant mashing device for preparing a plant preservative, comprising a juice outlet mechanism 2, the juice outlet mechanism 2 includes a mash juice cylinder 21, the bottom of the mash juice cylinder 21 is provided with an opening, and the size of the opening is compatible with the size of the baffle plate 28 At the same time, the baffle plate 28 will generate magnetism after being energized. At the same time, the magnetism is the same as the magnetic pole of the first fixed magnet 29. The baffle plate 28 is used to control the opening and closing of the pounding juice cylinder 21, so that the juice after pounding medicine can be automatically moved along the opening. Store, utilize first fixed magnet 29 to control the opening and closing of baffle plate 28 simultaneously, the inside of mashing juice tube 21 is movably connected with air bag 22, is provided with connecting rod between air bag 22 and push plate 23, and the surface of this conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com