Nondestructive testing and grading device and method for pineapples

A non-destructive testing and grading device technology, applied in sorting, color/spectral characteristic measurement, etc., can solve the problem of high complexity, and achieve the effect of accurate detection position and reliable detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

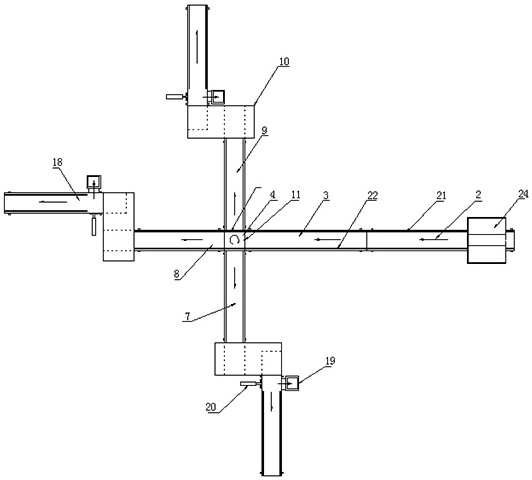

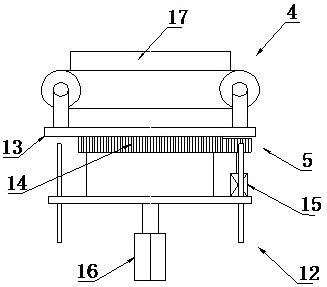

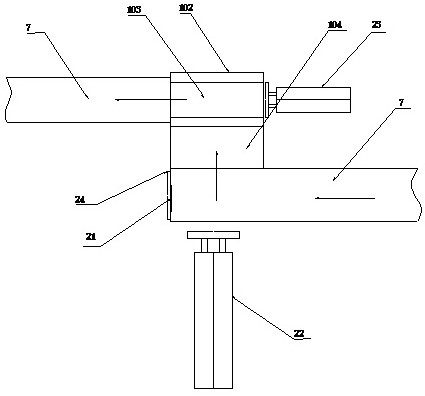

[0055] refer to Figure 1-5 , a pineapple non-destructive testing and grading device, comprising a controller 1, a first conveyor belt 2, a second conveyor belt 3 connected to the first conveyor belt 2, a dynamic weighing conveyor 4 arranged at the end of the second conveyor belt 3, The below of described dynamic weighing conveyor 4 is provided with through turntable module 5, and described turntable module 5 is used for driving dynamic weighing conveyor 4 to rotate 360 ° in horizontal direction; The belt is driven forward and reverse by the first motor 6, and the front, left and right sides of the dynamic weighing conveyor 4 are respectively provided with a third conveyor belt 7, a fourth conveyor belt 8, and a fifth conveyor belt 9; The ends of the third conveyor belt 7, the fourth conveyor belt 8, and the fifth conveyor belt 9 are respectively connected with non-destructive testing equipment 10 based on visible light / near infrared; the conveying speed of the second convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com