Quantitative material injection equipment for moon cake manufacturing

A moon bar and equipment technology, which is applied in the field of quantitative injection equipment for moon bar production, can solve the problems of labor consumption, different quantities of peanuts or beans, affecting the quality and taste of moon bar, and achieve the effect of improving quality and saving manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

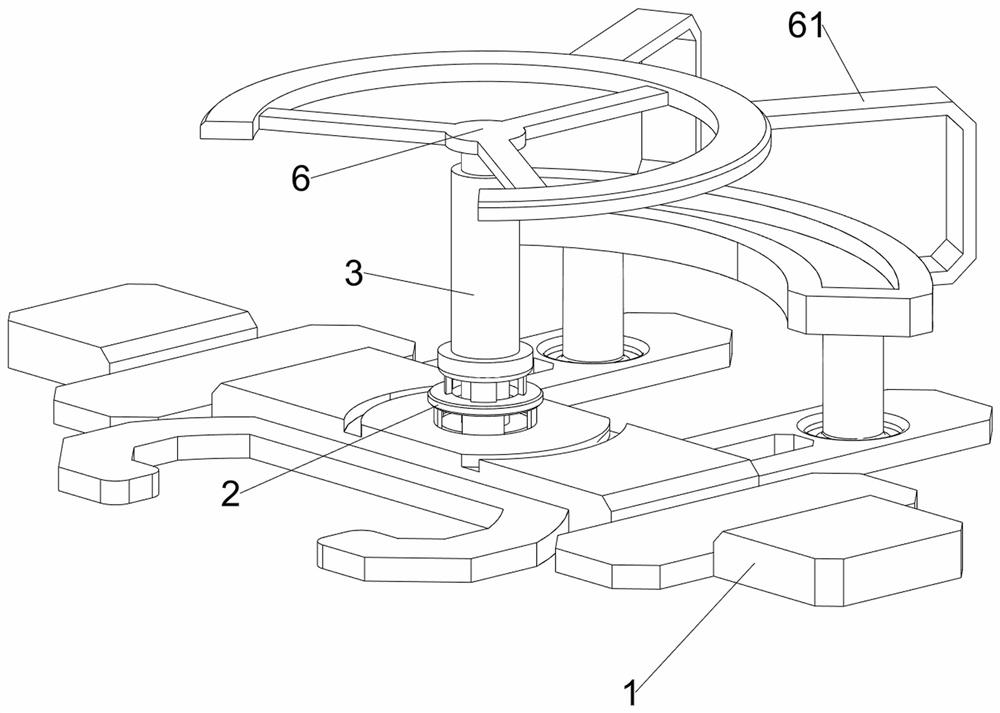

[0041] Quantitative material injection equipment for making a moon, such as Figure 1-8As shown, it includes a frame 1, a bearing seat 2, a hollow rotating shaft 3, a rotating disk 4, a fixed ring 6, a first connecting block 61, a quantitative mechanism 7 and a driving mechanism 8, and an anti-slip mat is installed on the bottom of the frame 1, which has a non-slip As a result, a bearing seat 2 is connected in the middle of the top of the frame 1, a hollow rotating shaft 3 is connected inside the bearing seat 2, and a rotating disk 4 is installed on the upper part of the hollow rotating shaft 3, and the rotating disk 4 is evenly spaced along the circumferential direction with six hanging grooves 5, The material hanging groove 5 is used for hanging the material spoon, and two first connecting blocks 61 are installed on the rear side of the middle part of the frame 1, and the two first connecting blocks 61 are left and right symmetrical. Fixed ring 6, fixed ring 6 is rotationall...

Embodiment 2

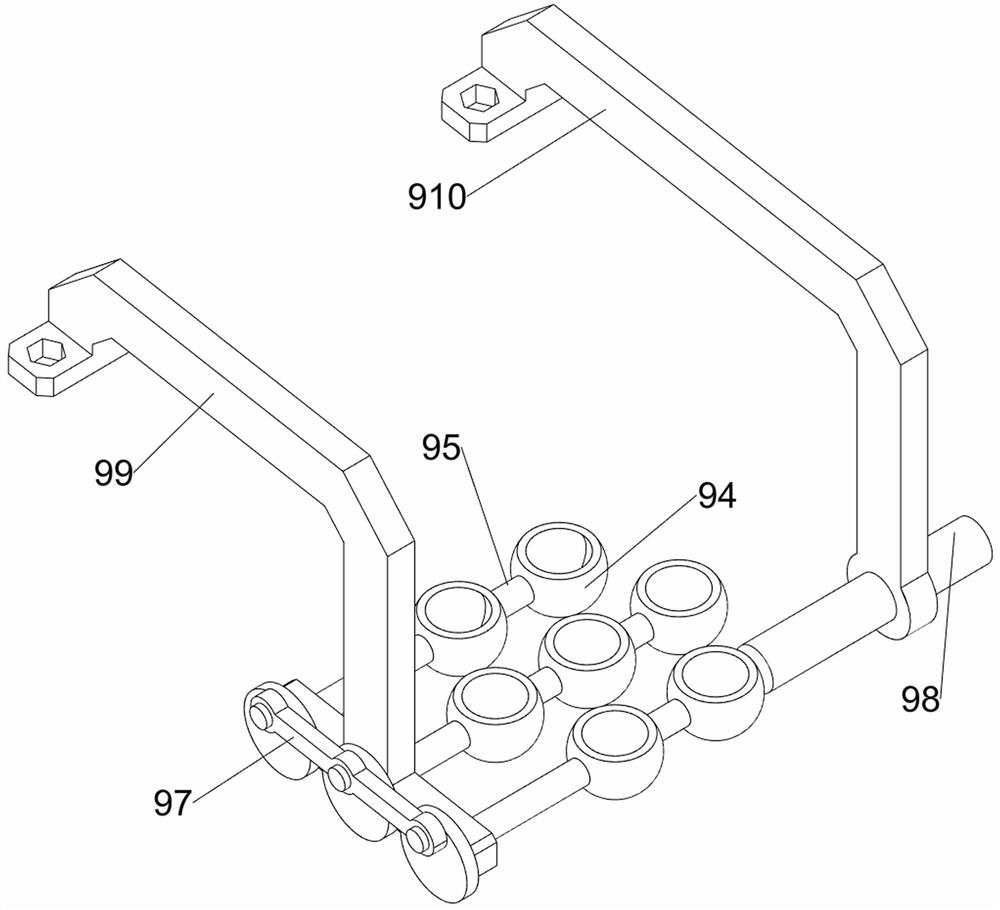

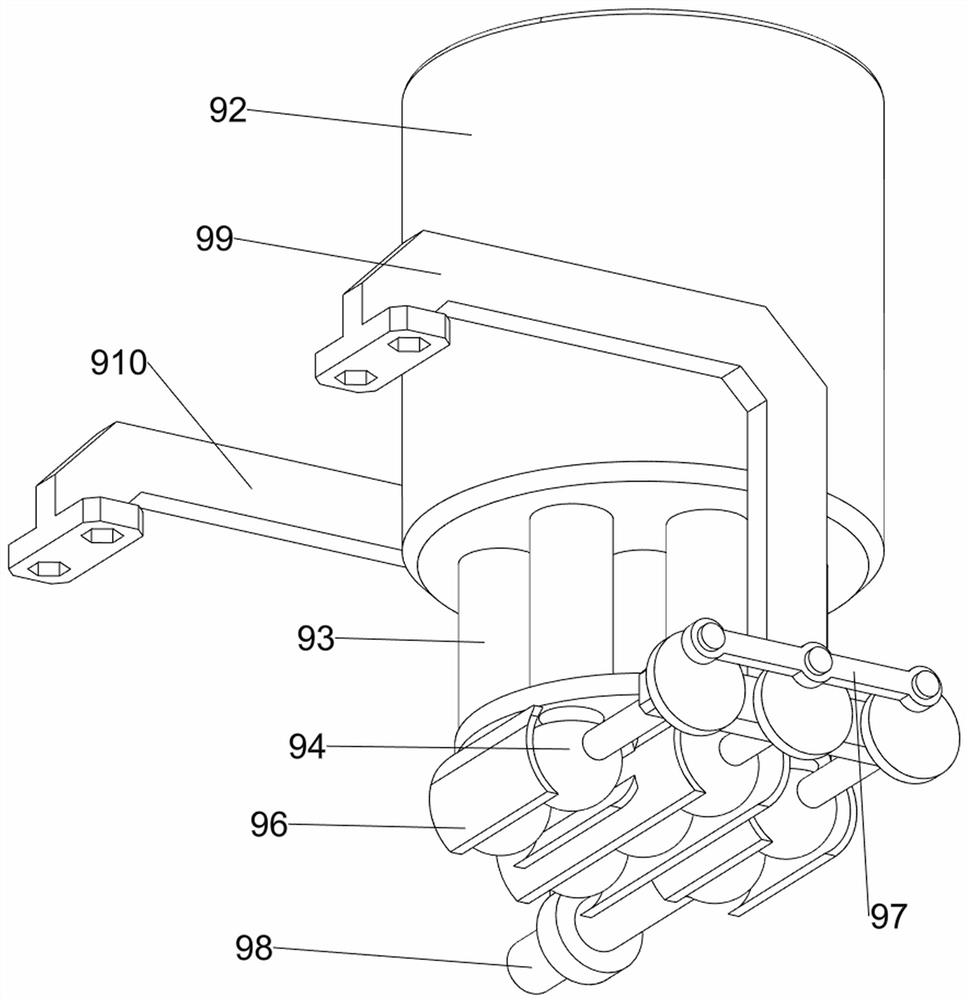

[0046] On the basis of Example 1, such as figure 1 , Figure 8 , Figure 9 with Figure 10 As shown, it also includes a feeding mechanism 9, which is used to add peanuts evenly and quantitatively. Ball 94, the second connecting rod 95, material retaining plate 96, connecting rod 97, first rotating shaft 98, the 3rd pole 99 and the 4th pole 910, the second pole 91 is installed on the right side of frame 1 top, the 2nd pole The second lower material barrel 92 is installed on the top of the two poles 91, and the second lower material barrel 92 is used to store peanuts. The third pole 99 and the fourth pole 910, the third pole 99 and the fourth pole 910 are symmetrical front and back, the bottom of the third pole 99 is evenly spaced and rotationally connected with three second connecting rods 95, the left and right sides Two receiving balls 94 are installed on the second connecting rod 95, and three receiving balls 94 are installed on the second connecting rod 95 in the middle...

Embodiment 3

[0051] On the basis of Example 2, such as figure 1 , Figure 13 with Figure 14 As shown, an automatic feeding mechanism 11 is also included, and the automatic feeding mechanism 11 is used to automatically add peanuts. The automatic feeding mechanism 11 includes a fifth pole 111, a third spring 112, a second rack 113 and a second gear 114. The fifth pole 111 is installed on the right side of the top of the frame 1, and the fifth pole 111 is located on the left side of the second pole 91. The top of the fifth pole 111 is slidingly connected with the second rack 113, and the bottom of the second rack 113 is connected with A third spring 112 is connected between the tops of the fifth poles 111, and a second gear 114 is installed on the rear side of the first rotating shaft 98. The second gear 114 meshes with the second rack 113, and the bottom of the second rack 113 is connected to the first rack. Rod 83 fits.

[0052] When the first connecting rod 83 moves to the right, it wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com