Preparation method of cobalt carbonate with wide particle size distribution

A cobalt carbonate and wide distribution technology, applied in the direction of cobalt carbonate, etc., can solve the problems of insufficient mixing and high requirements, and achieve the effect of uniform particle size distribution and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

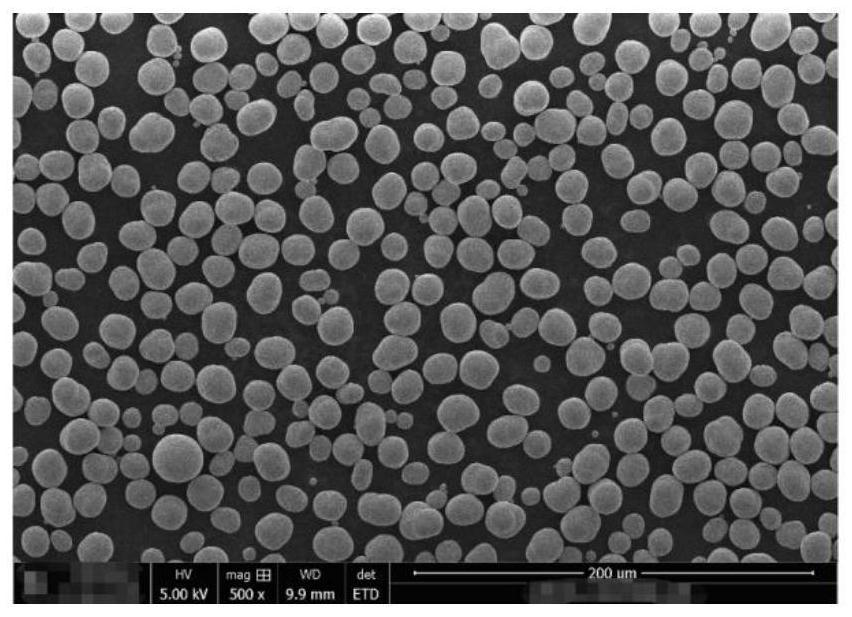

Embodiment 1

[0028] A preparation method of cobalt carbonate with wide distribution particle size, comprising:

[0029] (1) preparation cobalt concentration is 120g / L cobalt chloride solution, preparation concentration is the ammonium bicarbonate solution of 280g / L; Add pure water, ammonium bicarbonate solution successively in the first seed crystal kettle and prepare bottom liquid and stir, stir The mechanism is a double-layer stirring blade with a rotating speed of 150r / min; among them, the pH of the bottom liquid is 8.5, the concentration of ammonium bicarbonate in the bottom liquid is 5g / L, and the ratio of the volume of pure water added to the volume of the first seed crystal tank is 0.7 ;The temperature of the bottom liquid is 30°C;

[0030] (2) Cobalt chloride solution and ammonium bicarbonate solution are respectively added to the first crystal seed kettle simultaneously by feed flow rate of 250L / h and 500L / h to carry out the synthesis reaction, and the slurry pH in the first seed ...

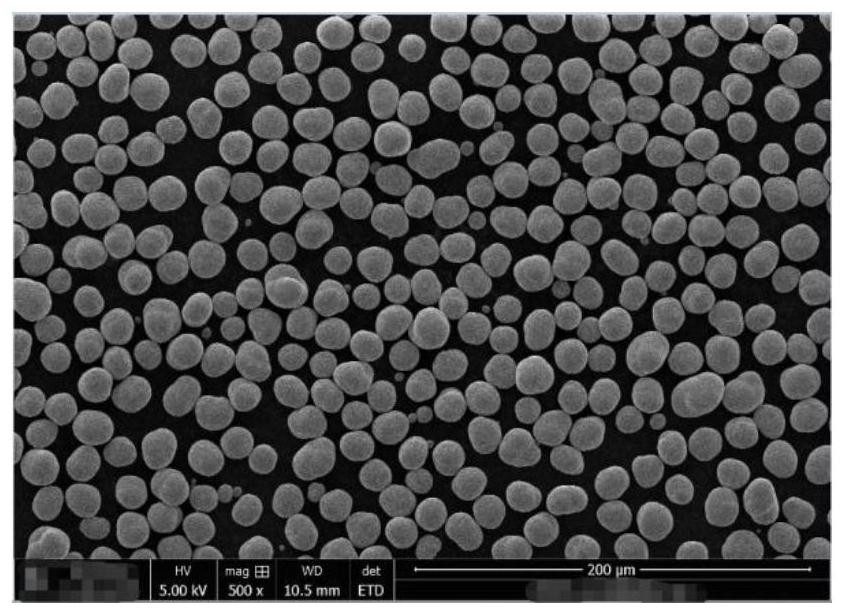

Embodiment 2

[0036] A preparation method of cobalt carbonate with wide distribution particle size, comprising:

[0037](1) preparation cobalt concentration is the cobalt chloride solution of 150g / L, preparation concentration is 200g / L ammonium bicarbonate solution; Add pure water, ammonium bicarbonate solution to prepare bottom liquid successively in the first seed crystal kettle and stir, stir The mechanism is a double-layer stirring blade with a rotating speed of 200r / min; wherein, the pH of the bottom liquid is 8.0, the concentration of ammonium bicarbonate in the bottom liquid is 3.5g / L, and the ratio of the volume of pure water added to the volume of the first seed crystal tank is 1.1; The temperature of the bottom liquid is 45°C;

[0038] (2) Cobalt chloride solution and ammonium bicarbonate solution are respectively added to the first crystal seed kettle to carry out synthetic reaction according to the feed flow rate of 350L / h and 700L / h, and the pH of the slurry in the first seed c...

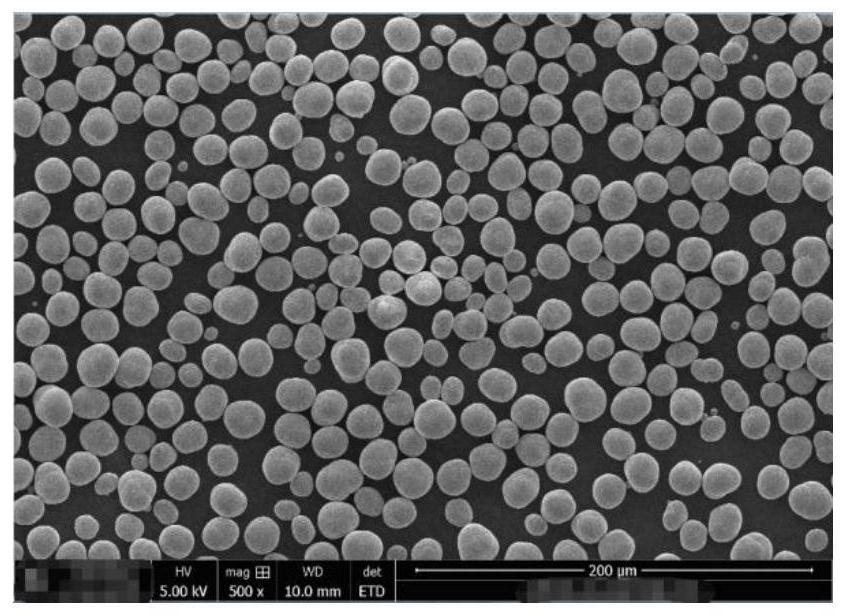

Embodiment 3

[0044] A preparation method of cobalt carbonate with wide distribution particle size, comprising:

[0045] (1) preparation cobalt concentration is the cobalt chloride solution of 180g / L, preparation concentration is the ammonium bicarbonate solution of 240g / L; In the first crystal seed still, add pure water, ammonium bicarbonate solution and prepare bottom liquid successively and stir, The stirring mechanism is a double-layer stirring blade, and the rotating speed is 300r / min; wherein, the pH of the bottom liquid is 7.5, the concentration of ammonium bicarbonate in the bottom liquid is 2g / L, and the ratio of the volume of pure water added to the volume of the first seed crystal tank is 1.5; The temperature of the bottom liquid is 60°C;

[0046] (2) Cobalt chloride solution and ammonium bicarbonate solution are respectively added to the first seed crystal kettle simultaneously by feed flow rate of 500L / h and 1000L / h to carry out the synthesis reaction, and the pH of the slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com