Glass tube processing equipment and production line

A technology for processing equipment and glass tubes, which is applied in the field of glass tube processing equipment and production lines, and can solve problems such as poor round mouth effect of glass tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

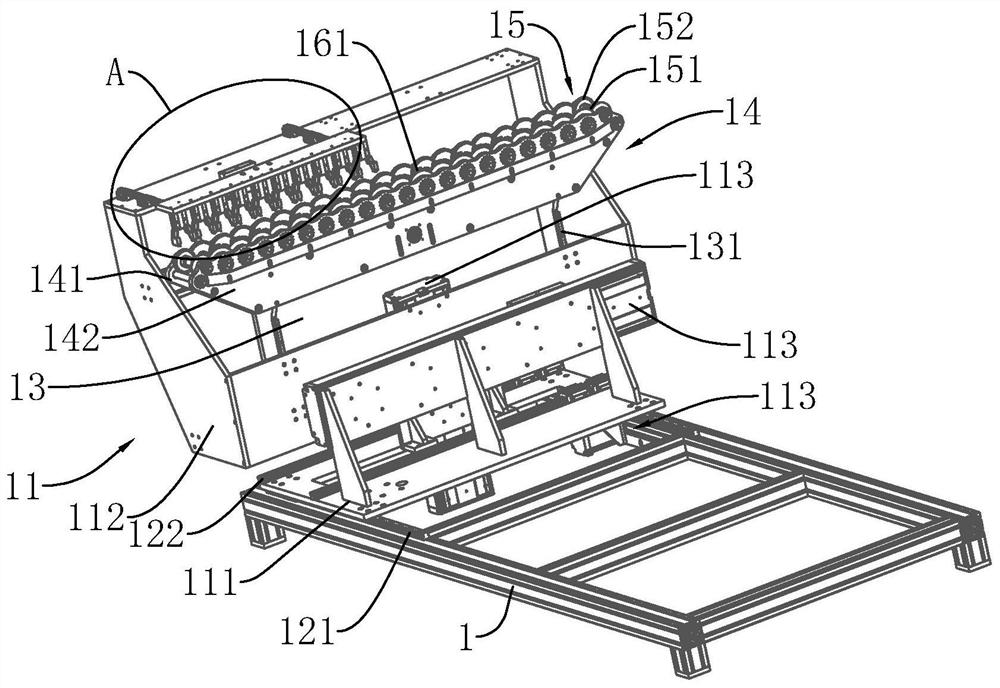

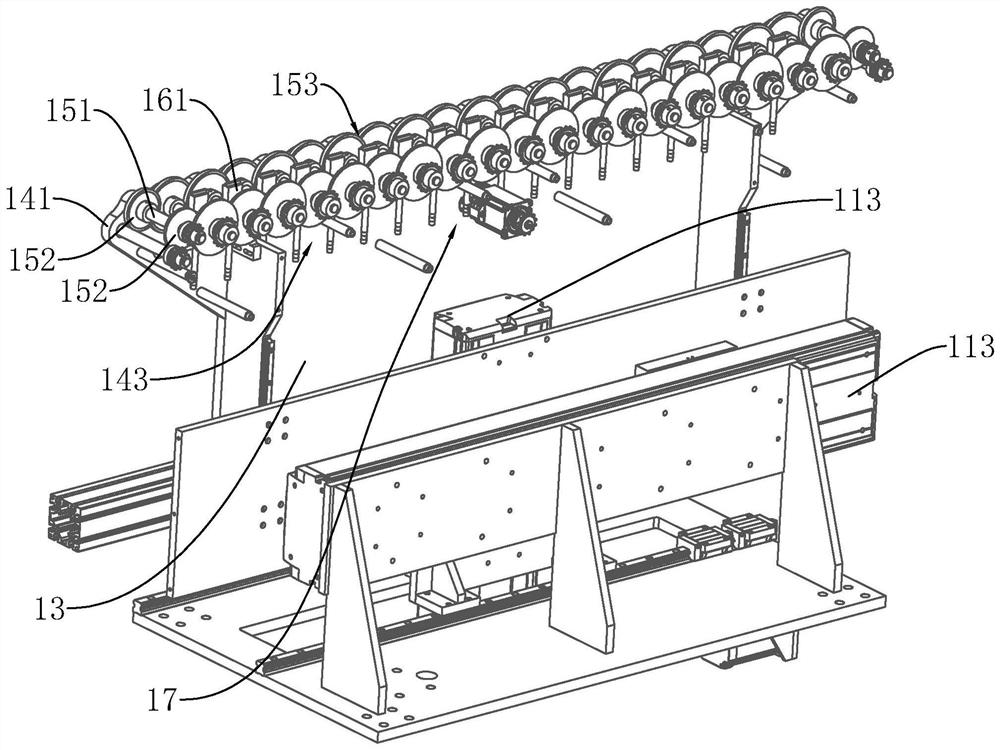

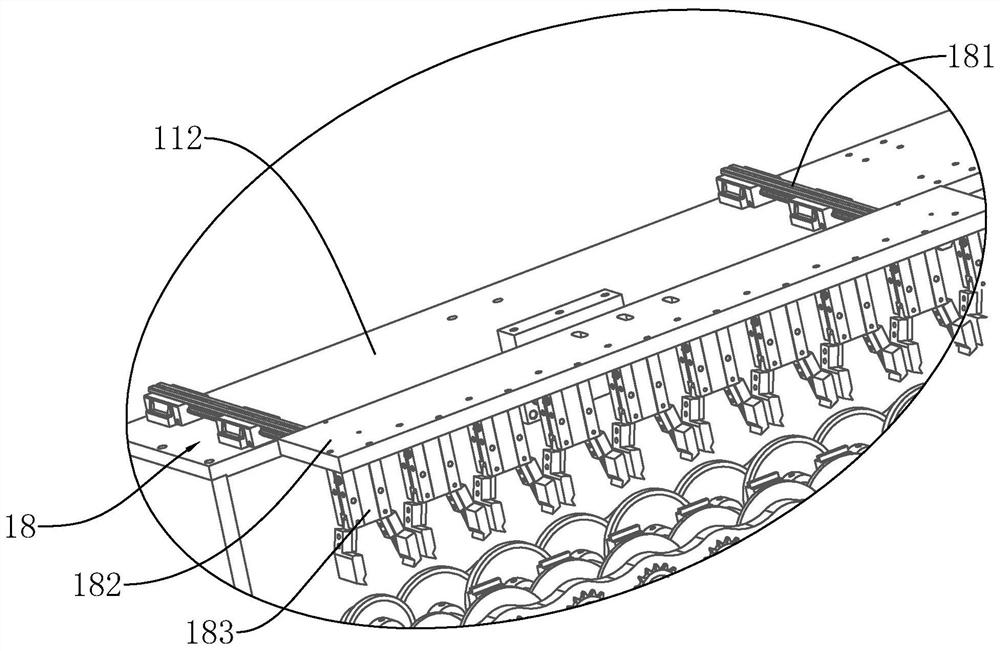

[0035] The following is attached Figure 1-8 The application is described in further detail.

[0036] refer to figure 1 and figure 2 , is a glass tube processing equipment disclosed in the present application, including a moving device, the moving device includes a fixed frame 1, and the fixed frame 1 is arranged on a support surface, which can be the ground or the surface of other objects. The fixed frame 1 is provided with a moving mechanism, and the moving mechanism includes a horizontal moving assembly and a jacking assembly. The horizontal moving assembly includes a moving frame 11 , a lateral moving piece 121 and a vertical moving piece 122 . The moving direction of the lateral moving member 121 is perpendicular to the moving direction of the longitudinal moving member 122 . Transversal moving part 121 is fixedly installed on fixed frame 1, and mobile frame 11 comprises horizontal frame 111 and longitudinal frame 112, and horizontal frame 111 and lateral moving part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com