A kind of production method for ammunition

A production method and elastic rubber technology, applied in the direction of explosives, explosive composite components, explosive processing equipment, etc., to achieve the effect of reducing manual participation, reducing the site, and reducing the generation of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

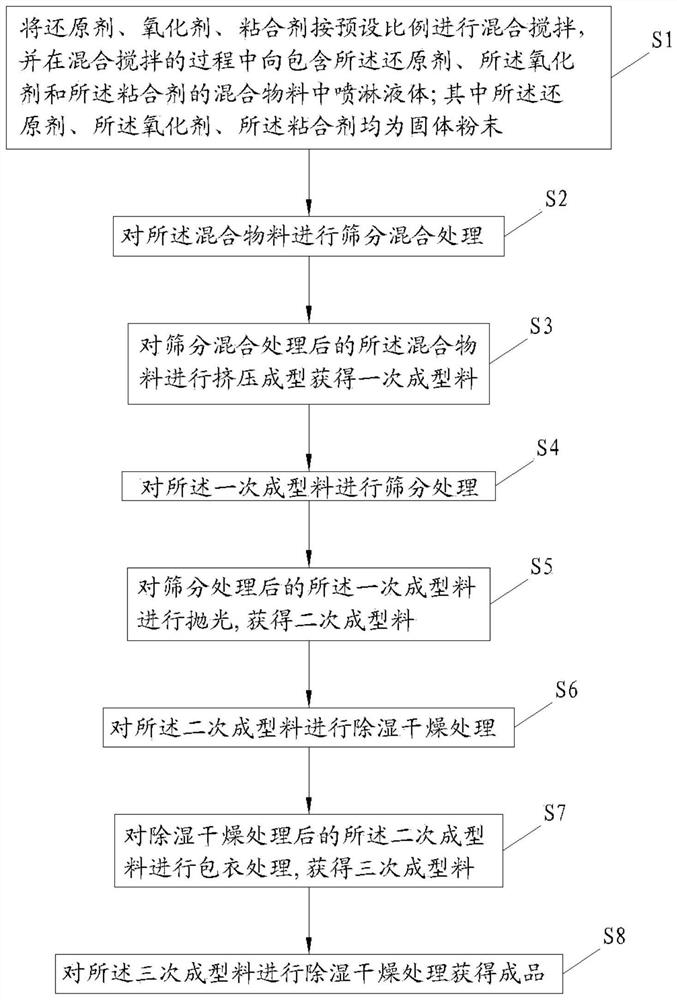

[0048] like figure 2 As shown, according to an embodiment of the present invention, a production method for ammunition of the present invention comprises:

[0049] S1. Mix and stir the reducing agent, the oxidizing agent, and the binder according to a preset ratio, and spray liquid into the mixture containing the reducing agent, the oxidizing agent, and the binder during the mixing and stirring process; wherein the reducing agent, the oxidizing agent, the The binders are all solid powders;

[0050] S2. Screening and mixing the mixed material;

[0051] S3. Extruding the mixed material after the screening and mixing treatment to obtain a primary molding material;

[0052] S4. Screen the primary molding material;

[0053]S5. Polish the primary molding material after screening to obtain secondary molding material;

[0054] S6. Dehumidify and dry the secondary molding material;

[0055] S7. The secondary molding material after the dehumidification and drying treatment is coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com