New energetic material with high reaction enthalpy and its preparation method

A technology of reaction and formulation, applied in the direction of explosives, etc., can solve the problems of low energy release efficiency and poor dispersion, and achieve the effects of high contact tightness, convenient preparation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The embodiment of the present invention also provides a method for preparing a novel energetic material with high reaction enthalpy, comprising the following steps:

[0026] S1. At 40°C, under the condition of ultrasonic stirring, dissolve the fluoropolymer in water, stir ultrasonically for 30-60 minutes, and make a 5-40% aqueous solution;

[0027] S2. Add a set amount of energetic metal or a mixture of energetic metal and energetic nonmetal to the aqueous solution obtained in step S1 in a vacuum glove box to form a mixed system; in this step, continue ultrasonic stirring, and the stirring time is 40~ 120min; the water content in the vacuum glove box is less than 1ppm; the oxygen content is less than 1ppm, and the box is filled with nitrogen;

[0028] S3. Put the mixed system obtained in step S2 in a vacuum drying oven, cast to form a film, and dry at 40° C. for >12 hours to obtain a dry film, which is a new formula energetic material.

Embodiment

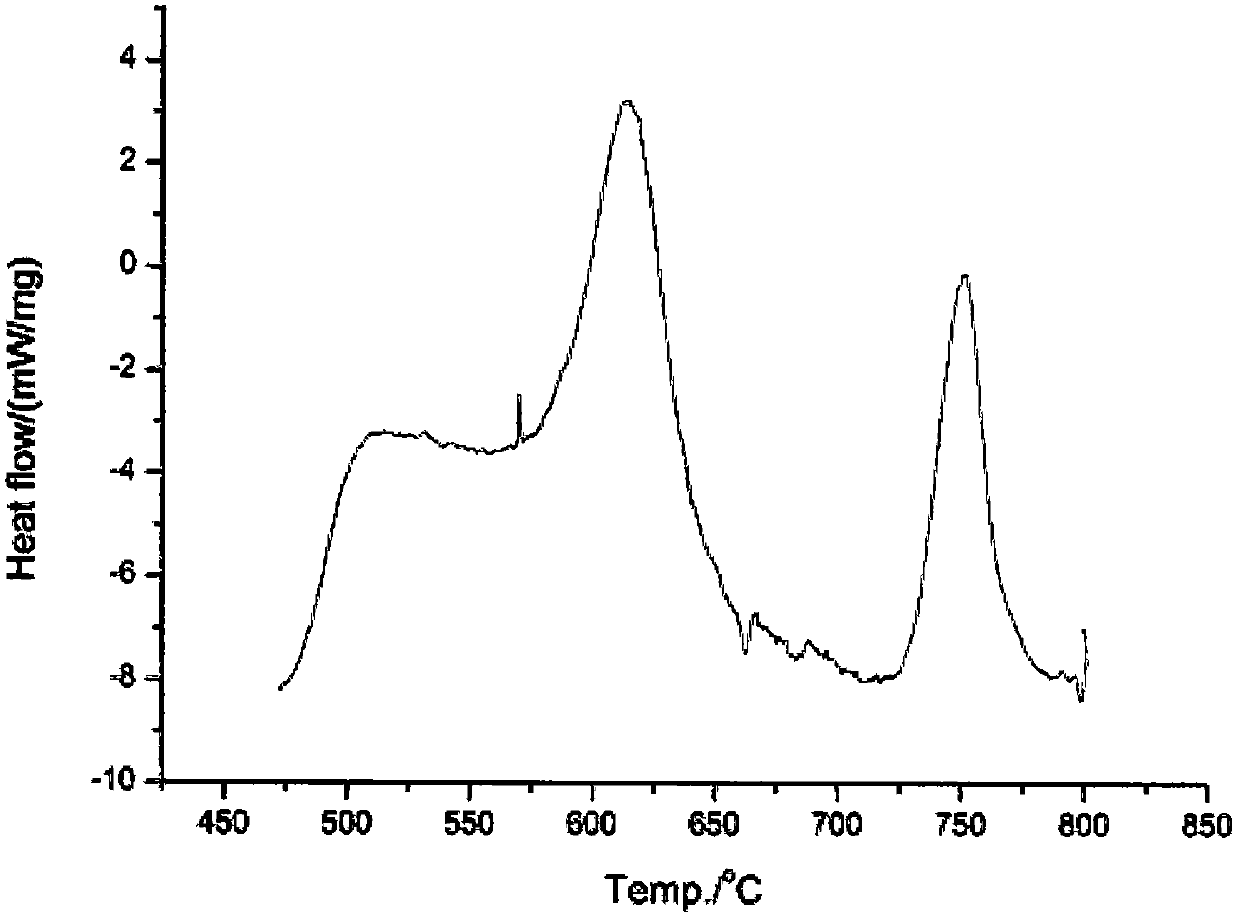

[0030] 1) At 40°C, under the condition of ultrasonic stirring, the perfluorocarboxylic acid resin with the -COOH group content of 0.6mmol / g was dissolved in water, and ultrasonically stirred for 30min to form a 20% aqueous solution; 2) in vacuum gloves Add nano-aluminum to the aqueous solution in the box, so that the weight ratio of perfluorocarboxylic acid resin to aluminum is 7 / 3 to make a mixed system; in this step, ultrasonic stirring is continued, and the stirring time is 60min; the water content in the vacuum glove box less than 1ppm; the oxygen content is less than 1ppm, and the box is filled with nitrogen; 3) the mixed system in 2) is placed in a vacuum drying oven, cast into a film, and dried at 40°C for > 12h, and the resulting dry film is the new product of the present invention. Formulated energetic materials. 4) In a differential scanning calorimeter, the film in 3) is subjected to a calorimetric test, and the results are shown in figure 1 , the calculated result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com