Wet blend fiber for well cementation, and preparation method thereof

A technology of fiber and wet mixing, which is applied in the field of wet mixing fiber for well cementing and its preparation, which can solve the problems of difficult mixing of fibers and achieve the effects of improving leakage prevention performance, facilitating cementing operation, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

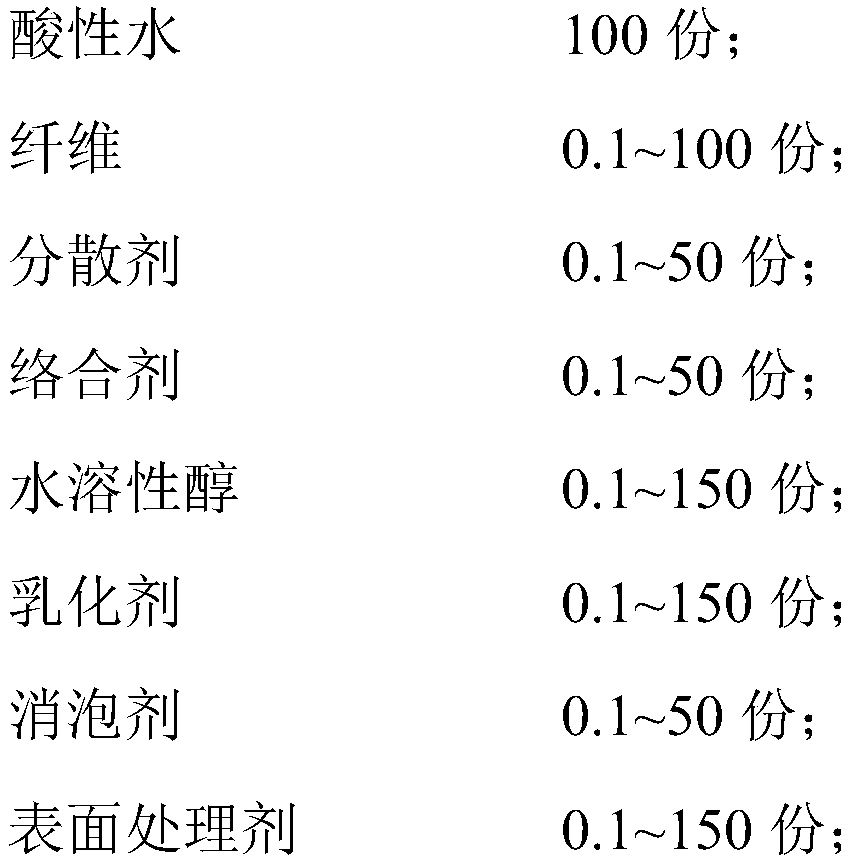

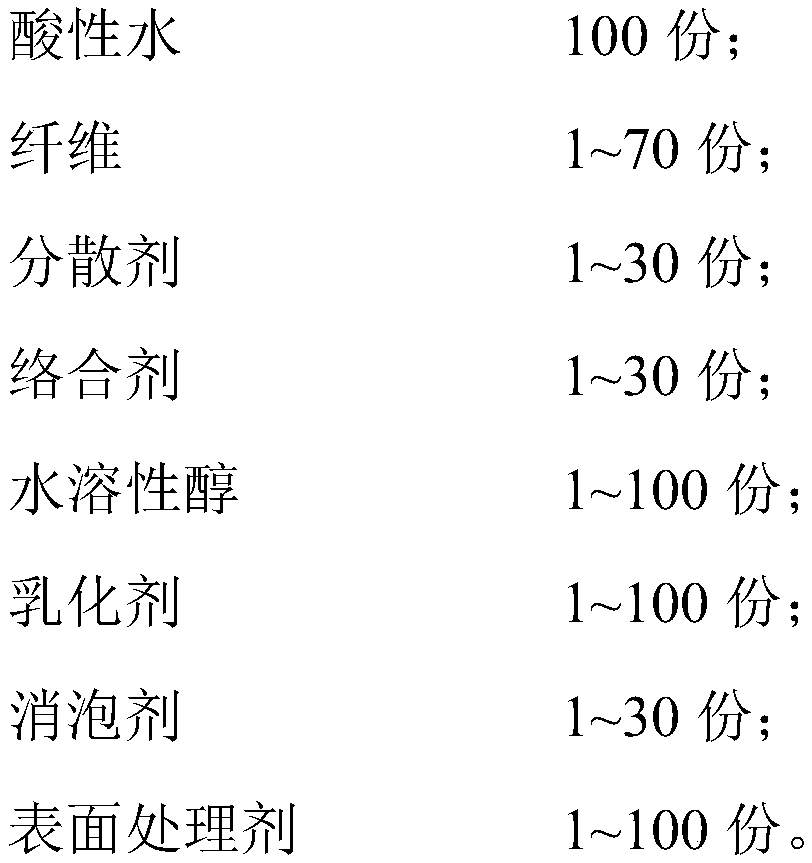

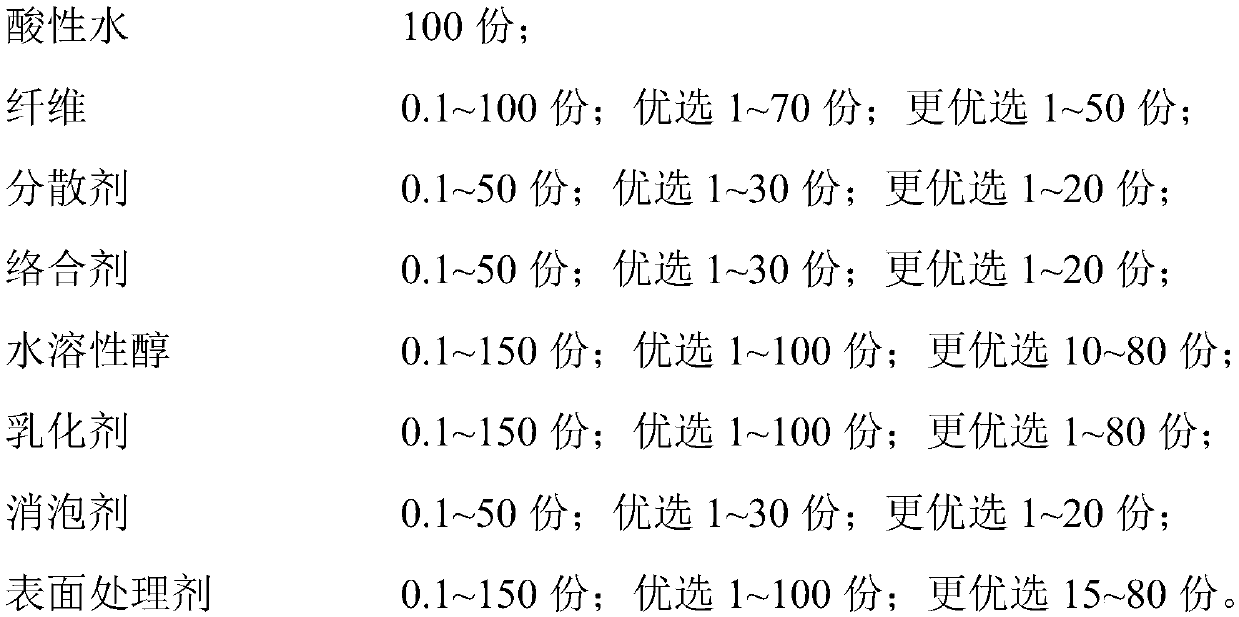

Method used

Image

Examples

Embodiment 1

[0041] Add hydrochloric acid to 100g of distilled water to make the pH of the solution 4.0, add 5g of polyether ammonium sulfate, add 20g of polypropylene fiber, stir and disperse at a speed of 1400r / min in the stirring disperser for 2 hours, and add 5g of ethylene glycol Disodium amine tetraacetate, stir the disperser at a speed of 1400r / min for 5min, add 20g of ethylene glycol, add 10g of polyoxyethylene sorbitan fatty acid ester, add 5g of simethicone, and stir the disperser After stirring at a speed of 1400r / min for 5min, add 40g of methacryloxypropyltrimethoxysilane, and stir with a stirring disperser at a speed of 1400r / min for 20min to prepare an aqueous fiber suspension.

Embodiment 2

[0043] Add hydrochloric acid to 100g of distilled water to make the pH of the solution 4.0, add 10g of polyether ammonium sulfate, add 40g of carbon fiber, stir and disperse at a speed of 1400r / min in the stirring disperser for 2 hours, add 10g of ethylenediaminetetra Disodium acetate, stir the disperser at 1400r / min for 5min, add 40g of ethylene glycol, add 20g of polyoxyethylene sorbitan fatty acid ester, add simethicone 10g, stir the disperser at 1400r / min After stirring at a speed of 1400 r / min for 5 minutes, add 50 g of methacryloxypropyl trimethoxysilane, and stir at a speed of 1400 r / min for 20 minutes to prepare an aqueous fiber suspension.

Embodiment 3

[0045] Add hydrochloric acid to 100g of distilled water to make the pH of the solution 4.0, add 2.5g of polyether ammonium sulfate, add 5g of polyester fiber, stir and disperse at a speed of 1400r / min in the stirring disperser for 2 hours, add 2.5g Disodium ethylenediamine tetraacetate, after stirring for 5 minutes with a stirring disperser at a speed of 1400r / min, add 12.5g of ethylene glycol, add 5g of polyoxyethylene sorbitan fatty acid ester, and add 2.5g of simethicone After stirring with a stirring disperser at a speed of 1400r / min for 5min, add 20g of methacryloxypropyltrimethoxysilane, and stir with a stirring disperser at a speed of 1400r / min for 20min to prepare an aqueous fiber suspension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com