Hydrogel with wet-state adhesion property as well as preparation method and application thereof

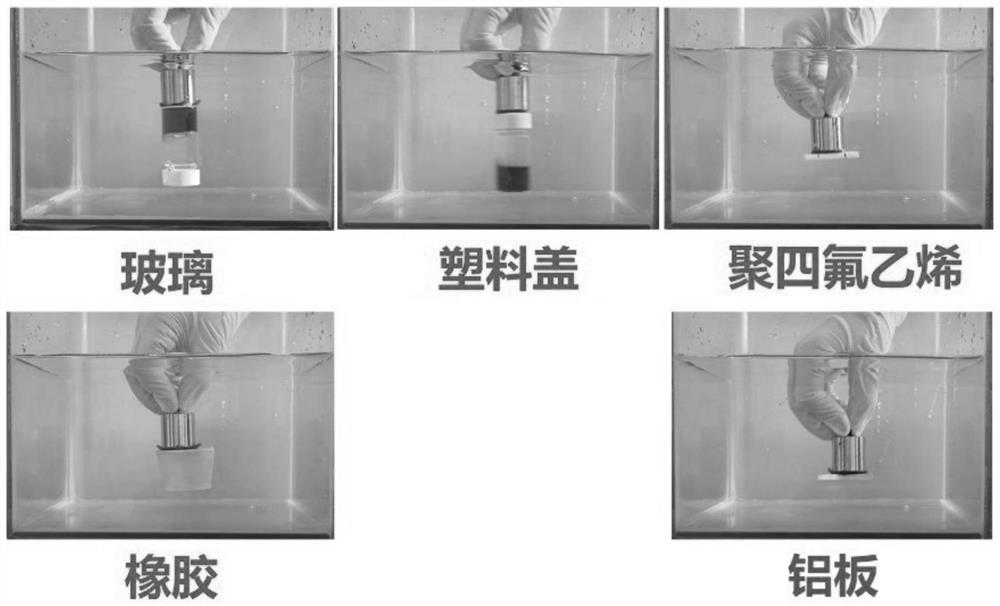

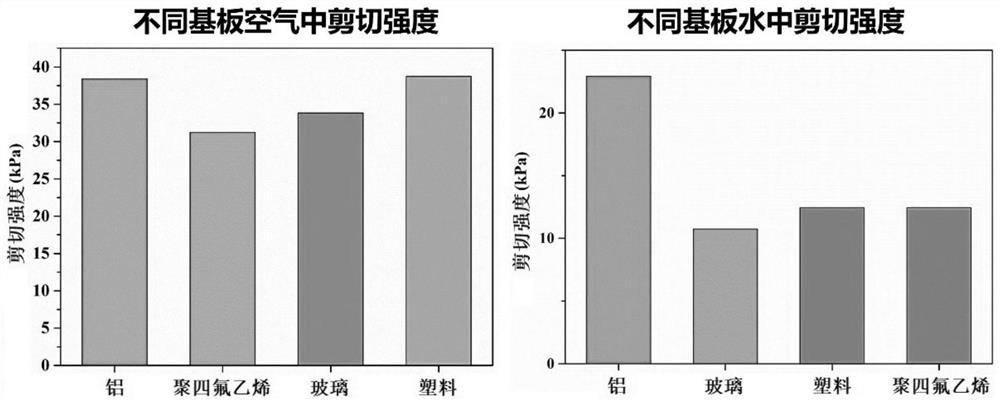

A hydrogel and performance technology, applied in the direction of adhesives, adhesive types, grafted polymer adhesives, etc., can solve problems such as insufficient adhesion strength, loss of adhesion performance, weak adhesion of hydrogels, etc. , to achieve the effects of simple preparation method, excellent mechanical properties and excellent adhesion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

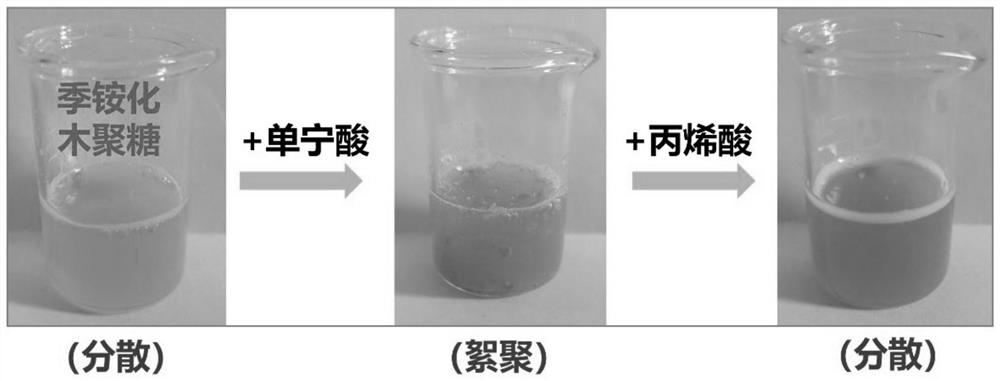

[0042] A kind of hydrogel with wet state adhesion performance, its preparation method comprises the following steps:

[0043] Disperse 100g of acrylic acid in 400mL of deionized water, then add 10g of quaternized xylan, 4.5g of tannic acid and 0.2g of N,N'-methylenebisacrylamide, stir well, and then add 0.5 g of ammonium persulfate was stirred evenly, and then the obtained mixture was poured into a mold, and cross-linked at 55° C. for 4 hours to obtain a hydrogel with wet adhesion properties.

Embodiment 2

[0045] A kind of hydrogel with wet state adhesion performance, its preparation method comprises the following steps:

[0046] Disperse 100g of acrylic acid in 230mL of deionized water, then add 20g of quaternized xylan, 5g of tannic acid and 0.3g of N,N'-methylenebisacrylamide, stir well, and then add 0.6 gram of ammonium persulfate, stirred evenly, then poured the obtained mixture into a mold, and cross-linked at 60°C for 6 hours to obtain a hydrogel with wet adhesion properties.

Embodiment 3

[0048] A kind of hydrogel with wet state adhesion performance, its preparation method comprises the following steps:

[0049] Disperse 100g of acrylic acid in 150mL of deionized water, then add 30g of quaternized xylan, 5.5g of tannic acid and 0.4g of N,N'-methylenebisacrylamide, stir well, and then add Stir 0.8g of ammonium persulfate evenly, then pour the obtained mixture into a mold, and cross-link at 70°C for 7 hours to obtain a hydrogel with wet adhesion properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com