Optical polyester film

A polyester film, optical technology, used in optics, optical components, polyurea/polyurethane coatings, etc., can solve problems such as poor adhesion, achieve uniform light-resistant adhesion, less damage, and high product reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1 to 14

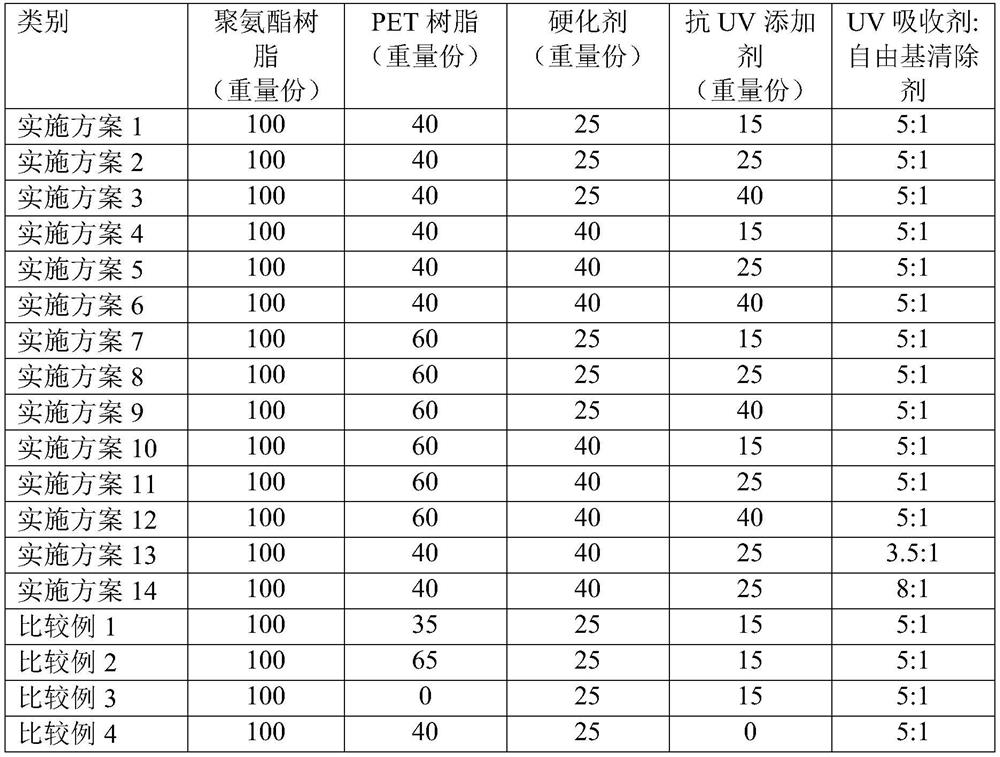

[0071] An optical polyester film was prepared by using a #5 wire bar with a primer composition (coating liquid) comprising the contents of each component (as shown in Table 1 below) per 100 parts by weight of polyurethane binder resin A 50 μm thick biaxially stretched polyester base film was applied, the primer layer was 0.1 μm thick after drying. The contents given in Table 1 show the solid contents of the respective components.

[0072]In addition, while preparing the primer composition as an aqueous dispersion, in addition to the components shown in Table 1, based on the total weight % of the coating liquid, 1.0 wt % of water and 10% by weight of an anionic surfactant in an aqueous dispersion of surfactant, and 0.5% by weight of an aqueous dispersion of silica particles comprising 30% by weight of water and 70% by weight of silica particles.

[0073] In addition, as shown in Table 1, the polyurethane resin in the primer composition is an aqueous dispersion of polyurethane ...

experiment example

[0081] (1) Measuring Adhesion

[0082] The adhesive force between the base film and the primer layer of the optical polyester films prepared in the embodiments and comparative examples was measured. For this, the surface of the primer layer is coated with an anti-glare coating liquid (AG coating liquid) by using a #5 wire bar, cured with UV rays, and formed in the film coated with the primer layer using a cutter. Lines were cut to arrange 2 mm x 2 mm squares in a 10 x 10 matrix. Cellophane tape (No. 405 available from NICHIBAN, 24mm wide) was attached to the film with the cut lines and a velvet rubbing tape was used to achieve a strong bond. After processing, remove the tape vertically. The area of the primer layer remaining on the attachment layer was visually observed to calculate the adhesive force using Equation 1 below.

[0083] Formula 1

[0084] Adhesion (%)=(1-area without defects / 100)*100(%)

[0085] (2) Measuring Lightfast Adhesion

[0086] The adhesive force...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com