Speed reduction clutch device of washing machine, washing machine and control method

A technology of clutch device and washing machine, applied to the control device of washing machine, washing device, other washing machines, etc., can solve problems such as complex structure, achieve good protection effect, reduce wear and tear, and reduce clothing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

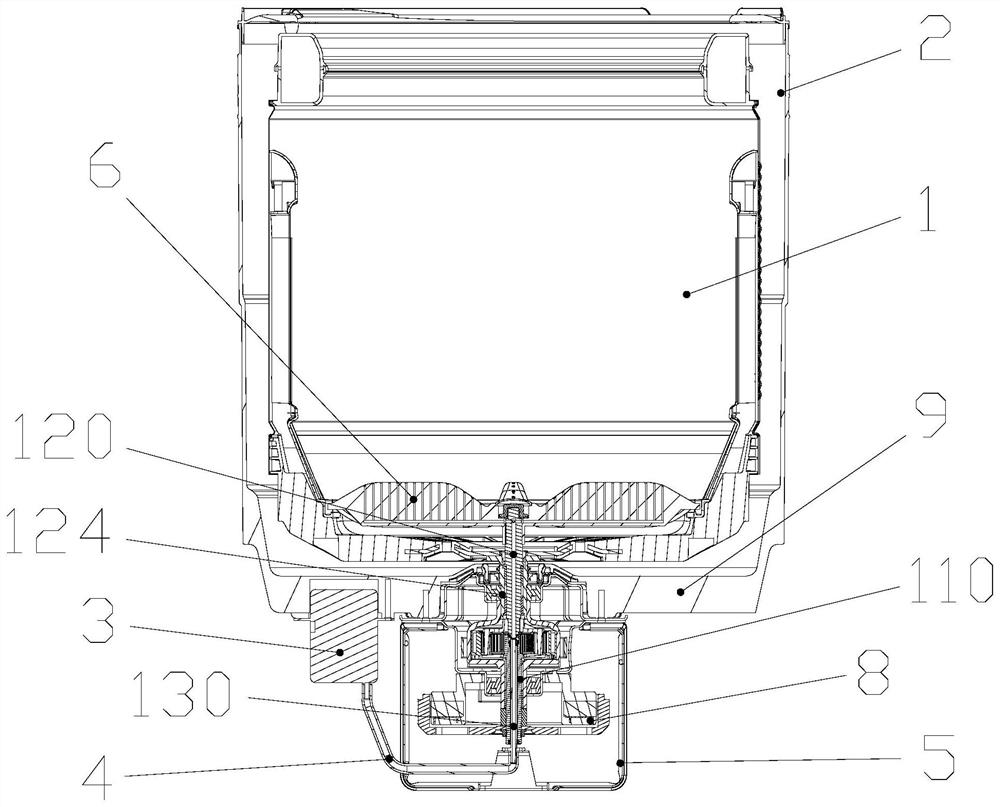

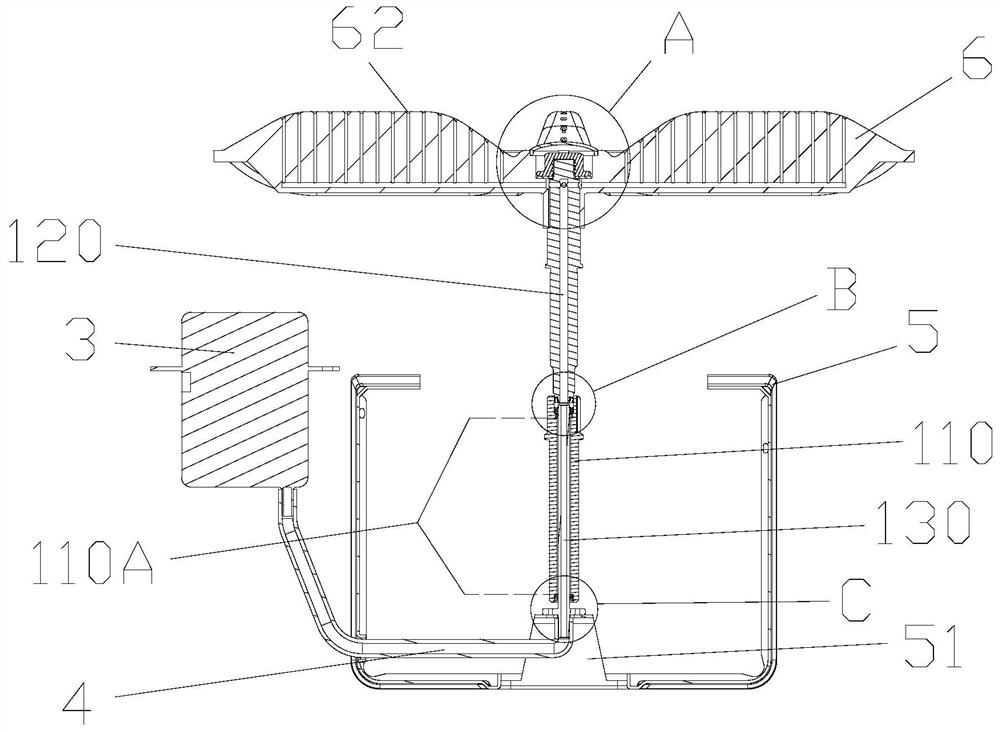

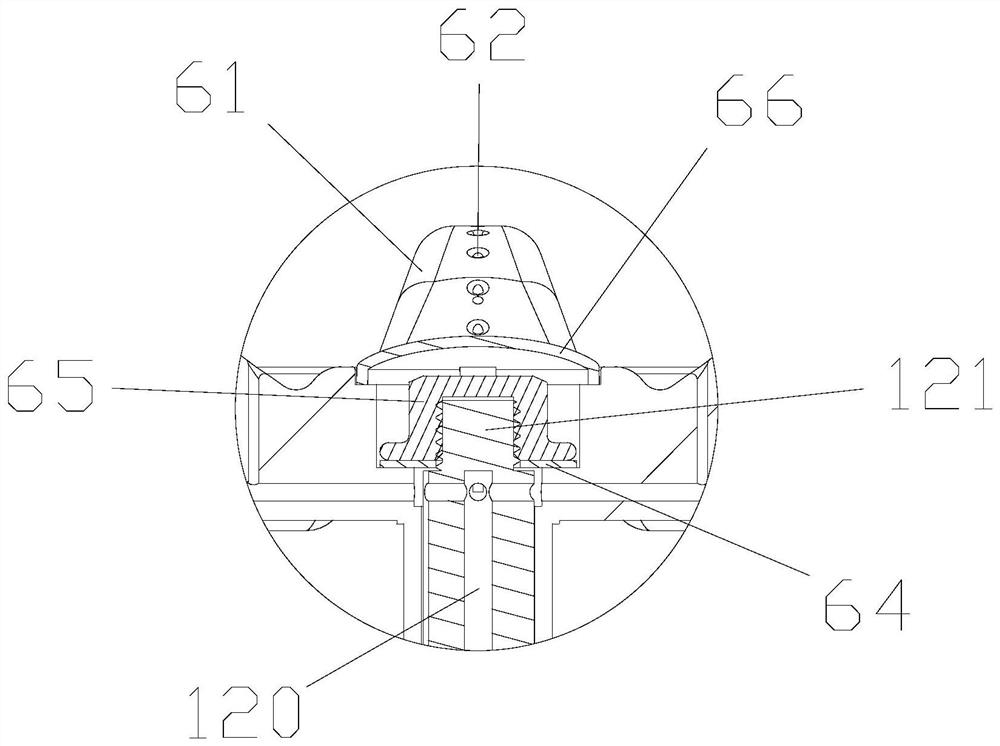

[0050] like Figure 1 to Figure 5 As shown, the deceleration clutch device described in this embodiment includes an input shaft 110 and an output shaft 120, both of which are hollow shafts, and are rotatably and sealedly connected to form a through hollow channel. The hollow channel provides a travel path for the gas, and the washing machine using the deceleration clutch device can realize the function of ventilating the inner tub 1 through the deceleration clutch device to generate air bubbles by connecting the hollow channel with the air source.

[0051] Further, as Figure 4 As shown, the lower end of the output shaft 120 is rotatably inserted into the hollow channel of the input shaft 110 , and a first sealing member 101 is provided between the outer wall of the output shaft 120 and the inner wall of the input shaft 110 . Specifically, the output shaft 120 includes a rotating shaft body and a plug portion 123 inserted into the input shaft 110 , and the first seal 101 is s...

Embodiment 2

[0072] like Figure 11 As shown, this embodiment provides a washing machine, and the washing machine has the deceleration clutch device described in the first embodiment. The difference between the washing machine and the first embodiment above is that the lower end of the communication pipe 130 is connected to the water inlet pipe 7, and the other end of the water inlet pipe 7 is connected to the water inlet valve of the washing machine.

[0073] In this embodiment, when the washing machine enters water, the water inlet valve is opened to supply water to the water inlet pipe 7 . The water flow enters the communication pipe 130 through the water inlet pipe 7 , and then passes through the input shaft 110 and the output shaft 120 in sequence, and finally passes through the water outlet on the surface of the pulsator 6 . The hole 67 goes into the inner tub 1 .

[0074] In this embodiment, the hollow channel of the deceleration clutch device is used to realize the function of wat...

Embodiment 3

[0076] This embodiment provides a non-porous inner tub washing machine, and the non-porous inner tub washing machine has the deceleration clutch device described in the first embodiment. The difference between the non-porous inner tub washing machine and the above-mentioned first embodiment is that the inner tub is a non-porous inner tub, the lower end of the communication pipe is connected with an air chamber, and the air chamber is connected with a pressure sensor through a pressure transmission pipe. The pressure sensor can detect the air pressure in the air chamber, so as to obtain the water pressure at the installation height of the air chamber, and then obtain the water level in the inner tub.

[0077] Further, the lower end of the communication pipe is also communicated with the drainage pipeline of the non-porous inner tub washing machine, and the water in the inner tub can be directly discharged through the hollow passage of the deceleration clutch device.

[0078] In...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap