Perfume composition for textiles

A composition and textile technology, applied in the field of fragrance compositions for textiles, can solve the problems of inability to store fragrance, volatile fragrance agents, and short fragrance storage time, and achieve excellent slow-release performance, long fragrance storage time, and easy adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

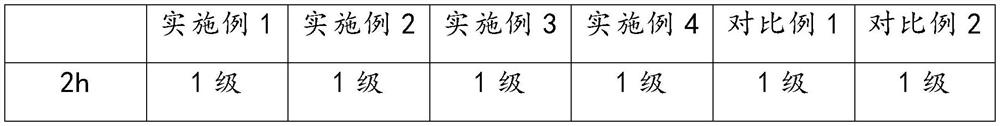

Examples

Embodiment 1

[0018] A kind of perfume composition for textiles, the composition comprises the following steps to make:

[0019] Step S1, add the degummed silk into the lithium bromide solution with a mass fraction of 80%, completely submerge it, put it in an oven at 50°C and dissolve it, shake it every 1 hour to prepare a protein solution, and dialyze it for 36 hours. During the dialyzing process, the total Change the water 6 times, change the water once every 3 hours for the first two times, change the water once every 6 hours for the last four times, centrifuge twice at a speed of 10000r / min, each time for 10min, separate out impurities, and obtain a purified protein solution, which is Solution a, the consumption ratio of controlling degummed silk and lithium bromide is 25g: 80g;

[0020] Add sodium carbonate into boiling water, stir at a constant speed until dissolved, add silk, completely submerged in the solution, cook for 50 minutes, stir once every 15 minutes, then remove the cooked...

Embodiment 2

[0024] A kind of perfume composition for textiles, the composition comprises the following steps to make:

[0025] Step S1, add the degummed silk into the lithium bromide solution with a mass fraction of 80%, completely submerge it, put it in an oven at 55°C and dissolve it, shake it every 1 hour to prepare a protein solution, and dialyze it for 36 hours. During the dialyzing process, the total Change the water 6 times, change the water once every 3 hours for the first two times, change the water once every 6 hours for the last four times, centrifuge twice at a speed of 10000r / min, each time for 10min, separate out impurities, and obtain a purified protein solution, which is Solution a, the consumption ratio of controlling degummed silk and lithium bromide is 25g: 80g;

[0026] Add sodium carbonate into boiling water, stir at a constant speed until dissolved, add silk, completely submerged in the solution, cook for 50 minutes, stir once every 15 minutes, then remove the cooked...

Embodiment 3

[0030] A kind of perfume composition for textiles, the composition comprises the following steps to make:

[0031] Step S1, add the degummed silk into the lithium bromide solution with a mass fraction of 80%, completely immerse it and put it in an oven at 60°C to dissolve it, shake it every 1 hour to prepare a protein solution, and dialyze it for 36 hours. During the dialyzing process, the total Change the water 6 times, change the water once every 3 hours for the first two times, change the water once every 6 hours for the last four times, centrifuge twice at a speed of 10000r / min, each time for 10min, separate out impurities, and obtain a purified protein solution, which is Solution a, the consumption ratio of controlling degummed silk and lithium bromide is 25g: 80g;

[0032] Add sodium carbonate into boiling water, stir at a constant speed until dissolved, add silk, completely submerged in the solution, cook for 50 minutes, stir once every 15 minutes, then remove the cooke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com