Concrete floor slab adopting hollow formwork and rapid construction method thereof

A technology of concrete and formwork, applied in the direction of formwork/formwork/work frame, joints of formwork/formwork/work frame, floor slabs, etc., can solve the problems of difficulty in meeting the construction period and low construction efficiency, and improve construction quality , high operating efficiency, and the effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

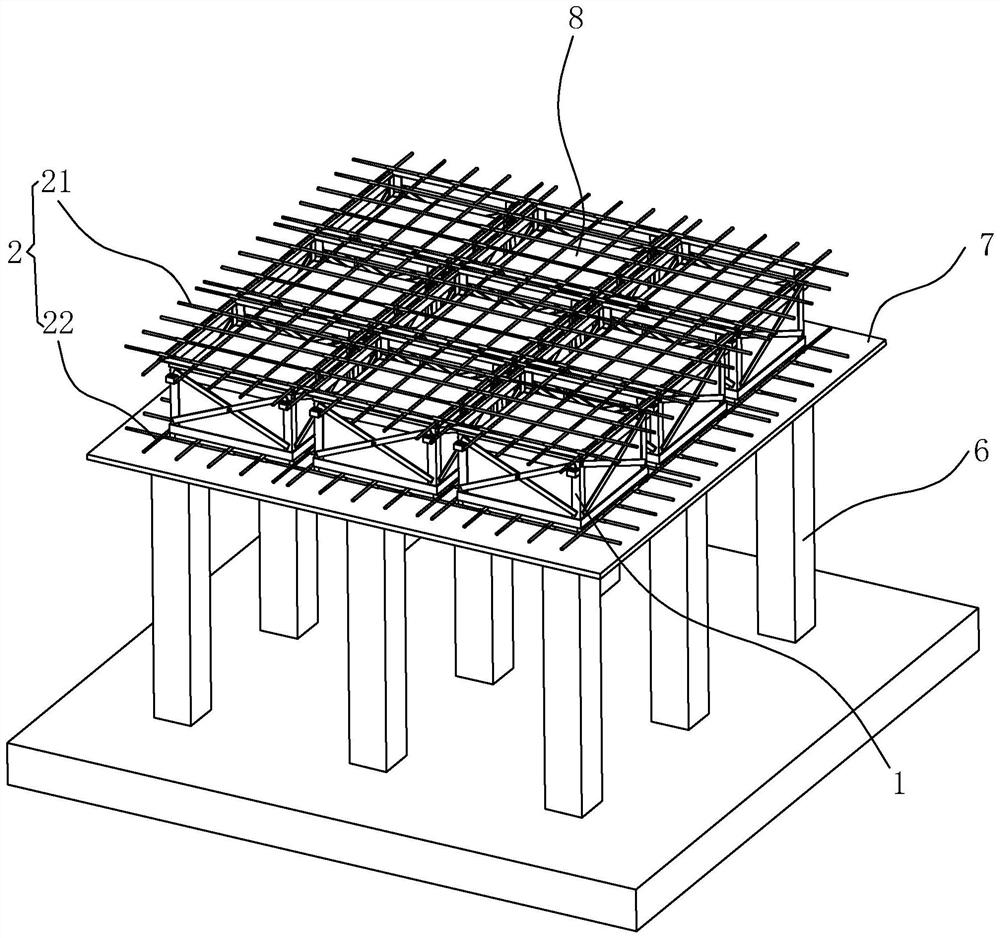

[0041] The embodiment of the present application discloses a concrete floor slab using a hollow formwork. refer to figure 1 , the ground is set horizontally, the ground is provided with several groups of vertically arranged support rods 6, and the support rods 6 are made of steel pipe; The common support has a formwork 7 arranged horizontally on the plane, and the formwork 7 is made of steel plate or plank.

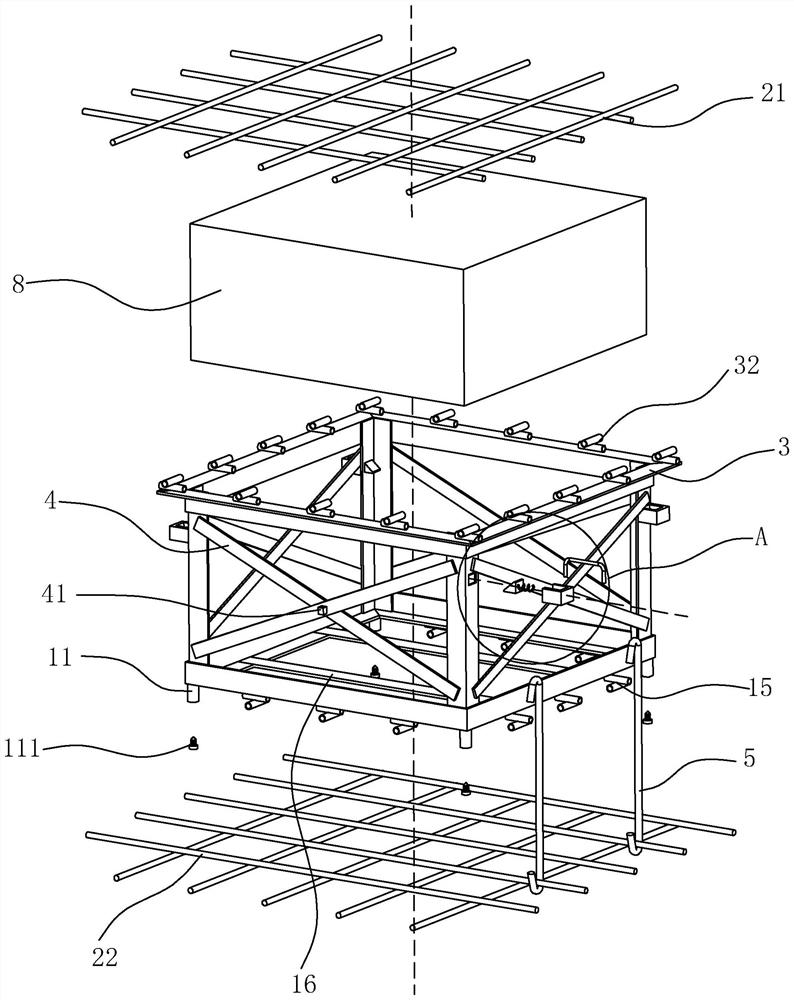

[0042] The concrete floor slab includes several groups of box bodies 1 and steel bar components 2 with the same specifications, and the upper end surface of the box body 1 is opened; the upper end surface of the formwork 7 is placed with several groups of mandrels 8 in a rectangular parallelepiped structure, and each group of mandrels 8 is made of foam material , the outer wall of the mandrel 8 is covered with aluminum foil. The box body 1 is placed on the upper end surface of the formwork 7, and each group of box bodies 1 is prefabricated before construction. Each gro...

Embodiment 2

[0050] A rapid construction method for a concrete floor slab using a hollow formwork, comprising the following steps:

[0051] a. Template 7 is installed, each group of support rods 6 is erected on the ground, and when each group of support rods 6 is installed, the diagonal braces are installed so that each group of support rods 6 is vertically set; and the formwork 7 is hoisted horizontally to each group On the support rod 6; at this time, the lower end surface of the formwork 7 fits with the upper end surface of each group of support rods 6;

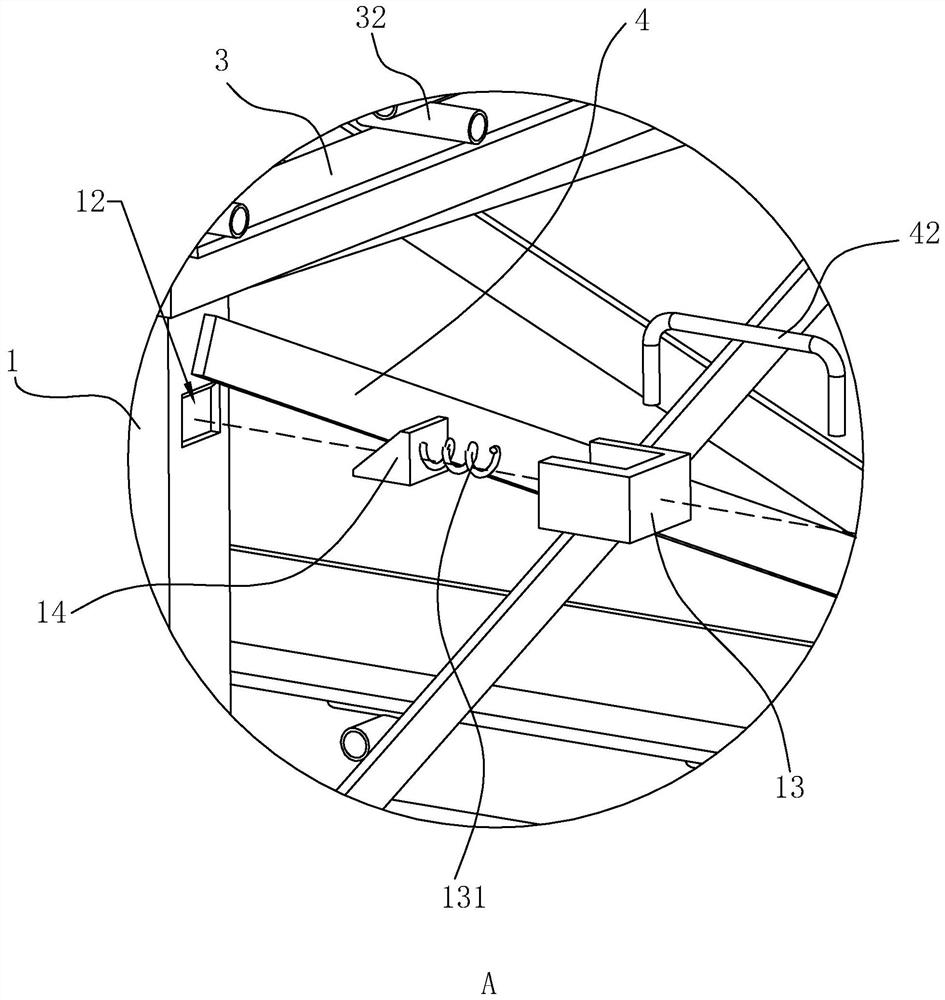

[0052] b. Mark the upper end surface of the formwork 7 to determine the placement position of each group of box bodies 1; each group of box bodies 1 is prefabricated, and each group of first positioning tube groups 15 and second positioning tubes are installed on the box body 1 Group 32, wedge-shaped block 14 and socket 41, each group of sealing screws 111 are threadedly connected with the legs 11; each group of boxes 1 is placed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com