Reinforcing method and structure for improving axial compression performance of concrete column

A concrete column and concrete technology, applied in building construction, building maintenance, construction, etc., can solve the problems of low improvement range, long maintenance period, and increased structure self-weight, so as to improve deformation capacity and durability, and simple construction method , Improving the effect of axial compression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] 1. A reinforcement method to improve the axial compression performance of concrete columns is as follows:

[0050] Step 1: Carry out on-site stakeout according to the design position or the position of the member to be reinforced;

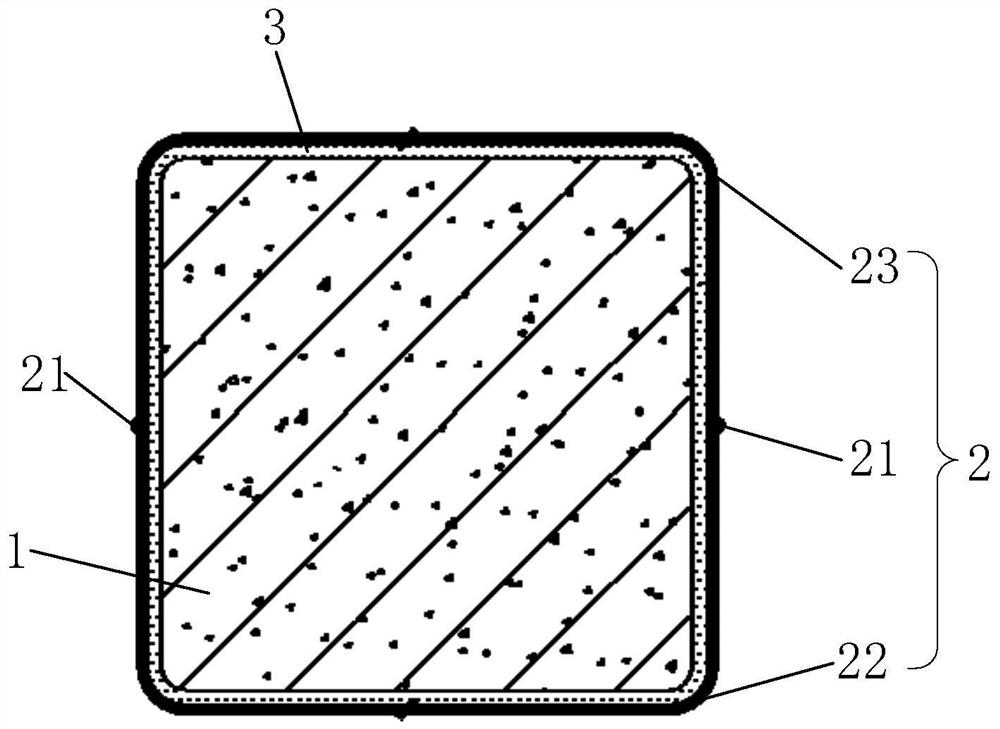

[0051] Step 2: Treat the surface of the concrete member 1, and remove the plaster layer cushion or other decorative surface layers;

[0052] Step 3: Use a grinding wheel or an angle grinder to grind the loose layer and oil stains on the surface of the concrete member 1 until the new concrete interface is completely exposed, and use compressed air to clean the floating ash on the surface, and then wipe it with acetone. The surface of the concrete member 1 must be Clean, grease-free, and keep dry; if there is unevenness on the surface of the treated concrete member 1, repair materials should be used to fill up the defective parts; After the surface is dry, proceed to the next step of construction;

[0053] Step 4: Derust and roughen the bondin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com