Flexible wall permeameter for realizing temperature-stress integrated control under dry-wet cycle

A dry-wet cycle, flexible wall technology, applied in the direction of permeability/surface area analysis, instruments, scientific instruments, etc., can solve problems such as unconsidered, permeability coefficient measurement error, unrealized automatic monitoring, etc., to reduce injection and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

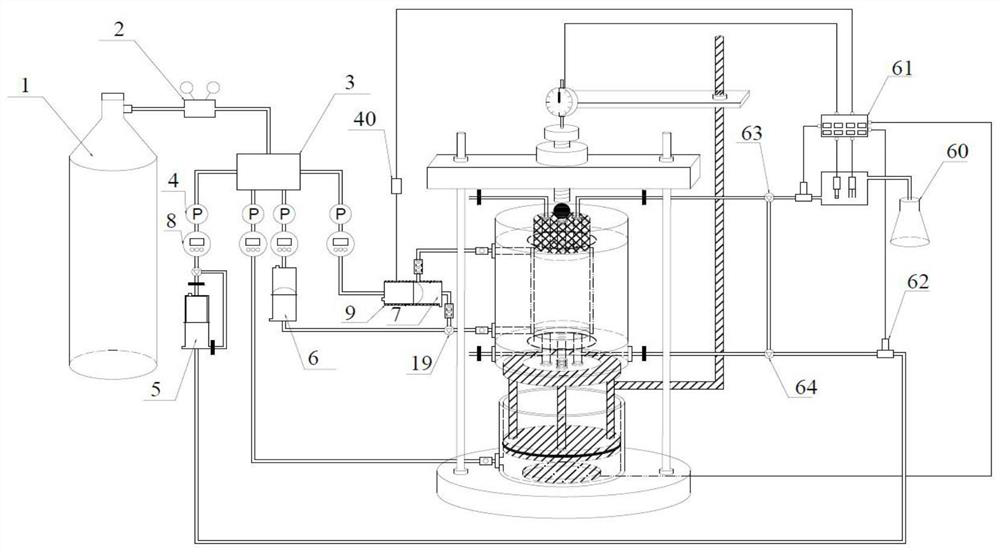

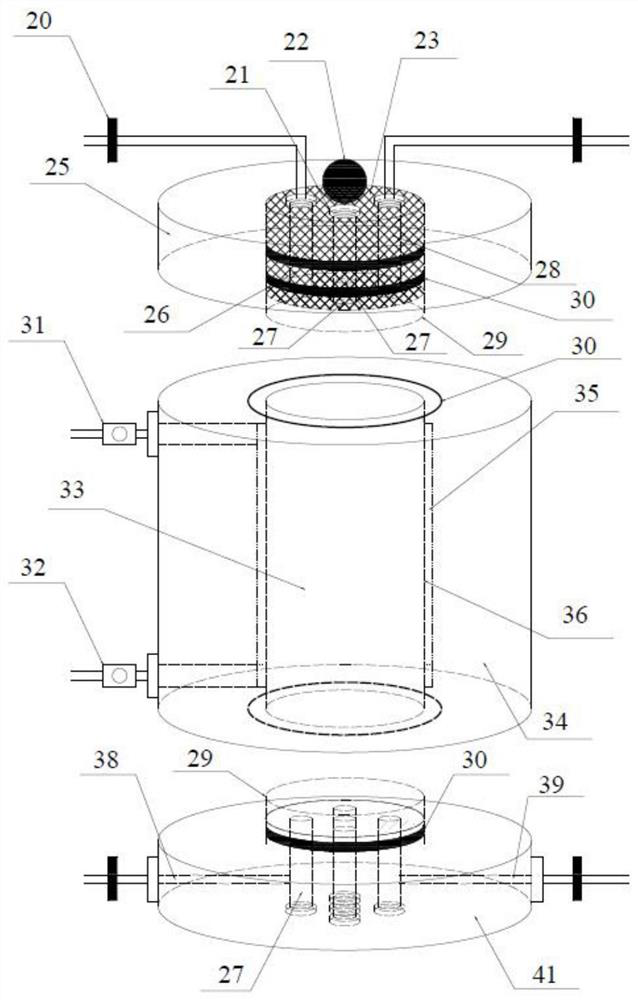

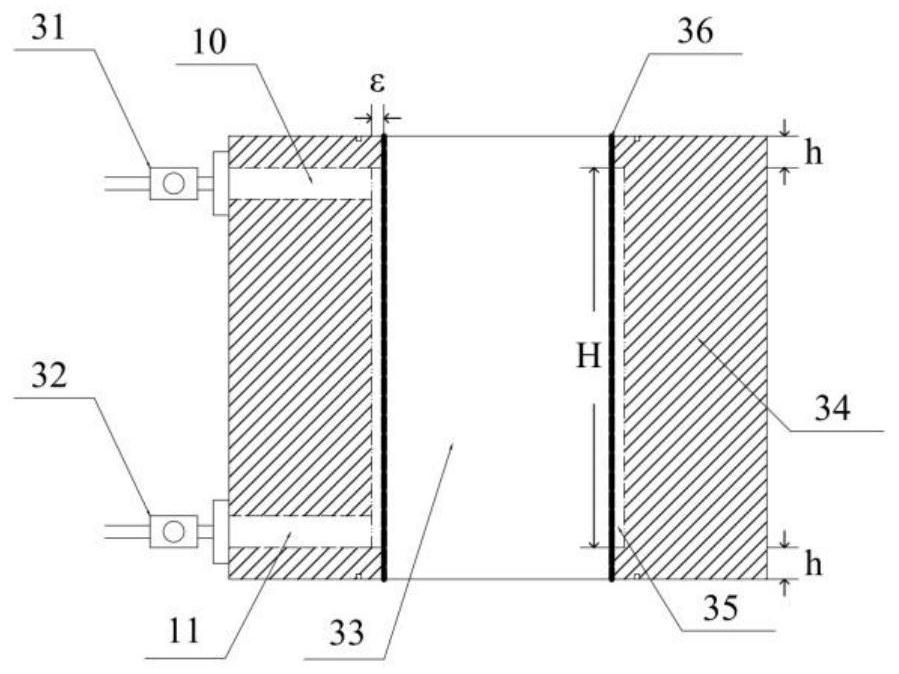

[0041] figure 1 It is a schematic diagram of the overall structure of the flexible wall permeameter in the embodiment of the present invention, figure 2 It is a schematic diagram of the structure of the test device in the embodiment of the present invention, Figure 4 It is a schematic structural diagram of the pressurizing device in the embodiment of the present invention, Figure 5 It is a schematic diagram of the structure of the injection chamber a in the embodiment of the present invention, Figure 6 It is a schematic diagram of the structure of the injection chamber b in the embodiment of the present invention, Figure 7 It is a schematic structural diagram of the injection chamber c in the embodiment of the present invention, Figure 8 It is a structural schematic diagram of the exudate automatic monitoring and collection device in the emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com