Soldering method for electric connection between mother board and electronic elements

A technology of electronic components and welding methods, which is applied in the field of welding where the main board and electronic components are electrically combined, can solve the problems of poor flatness of the welding surface, poor reliability, and low productivity, and achieve good coplanarity and improved reliability. , the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

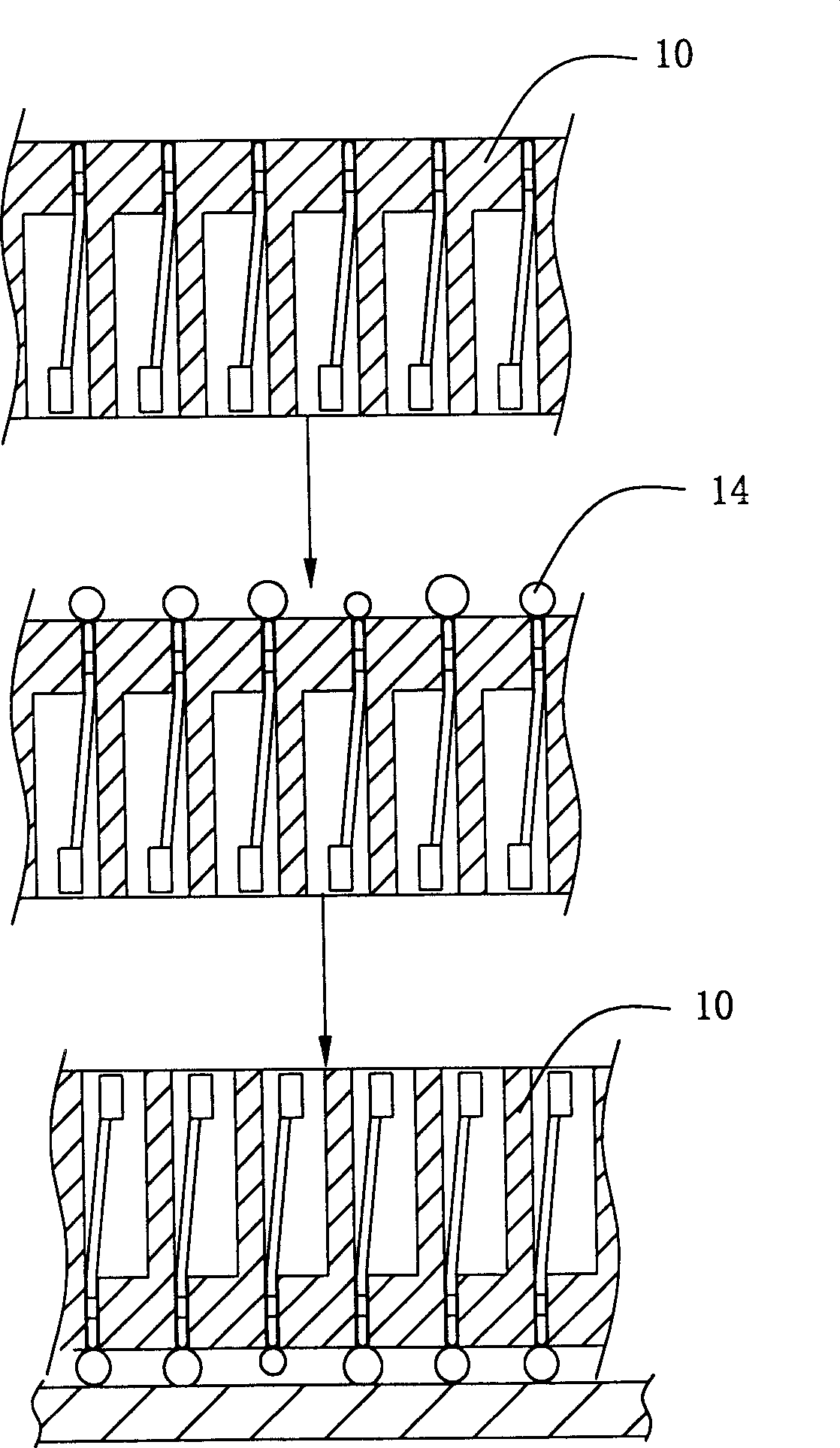

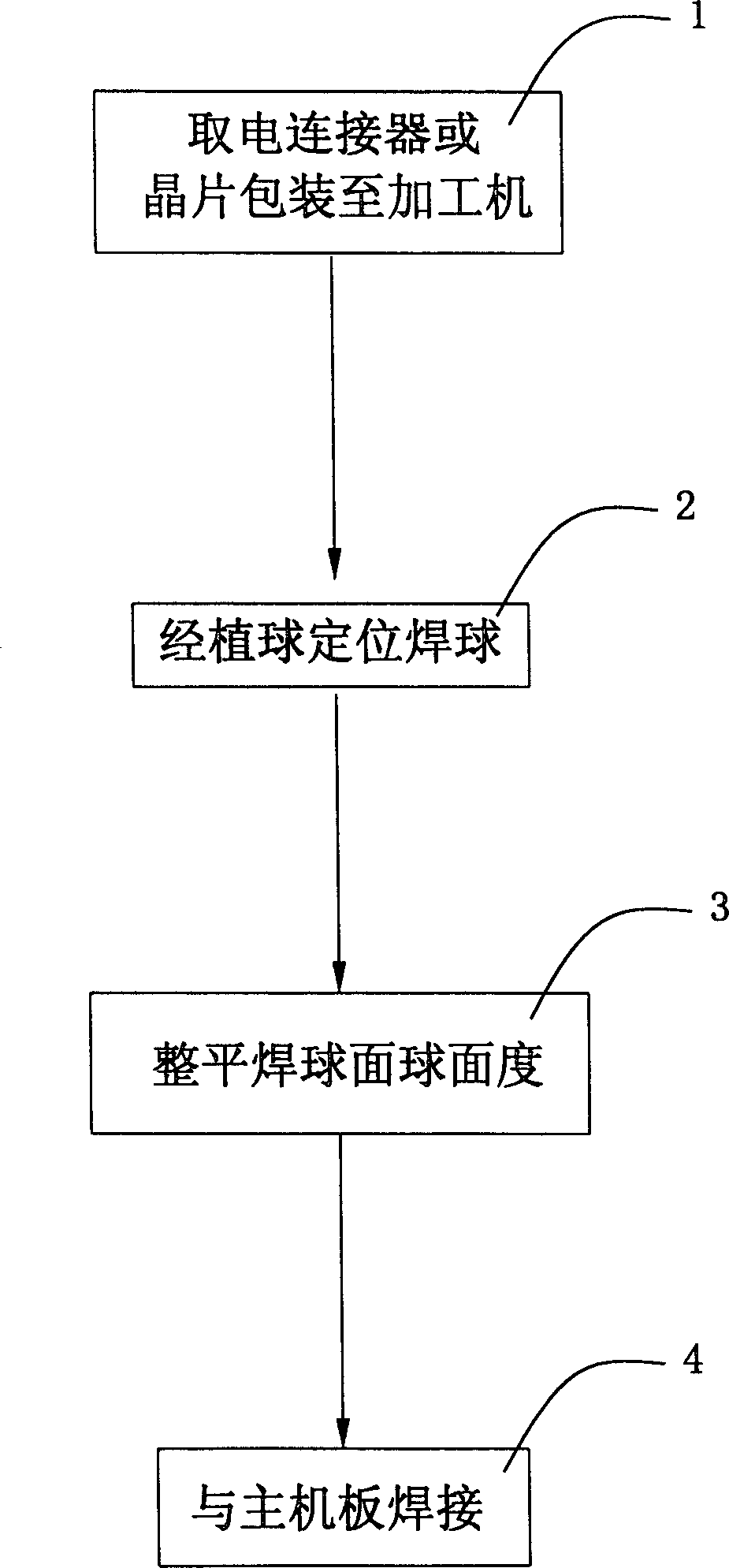

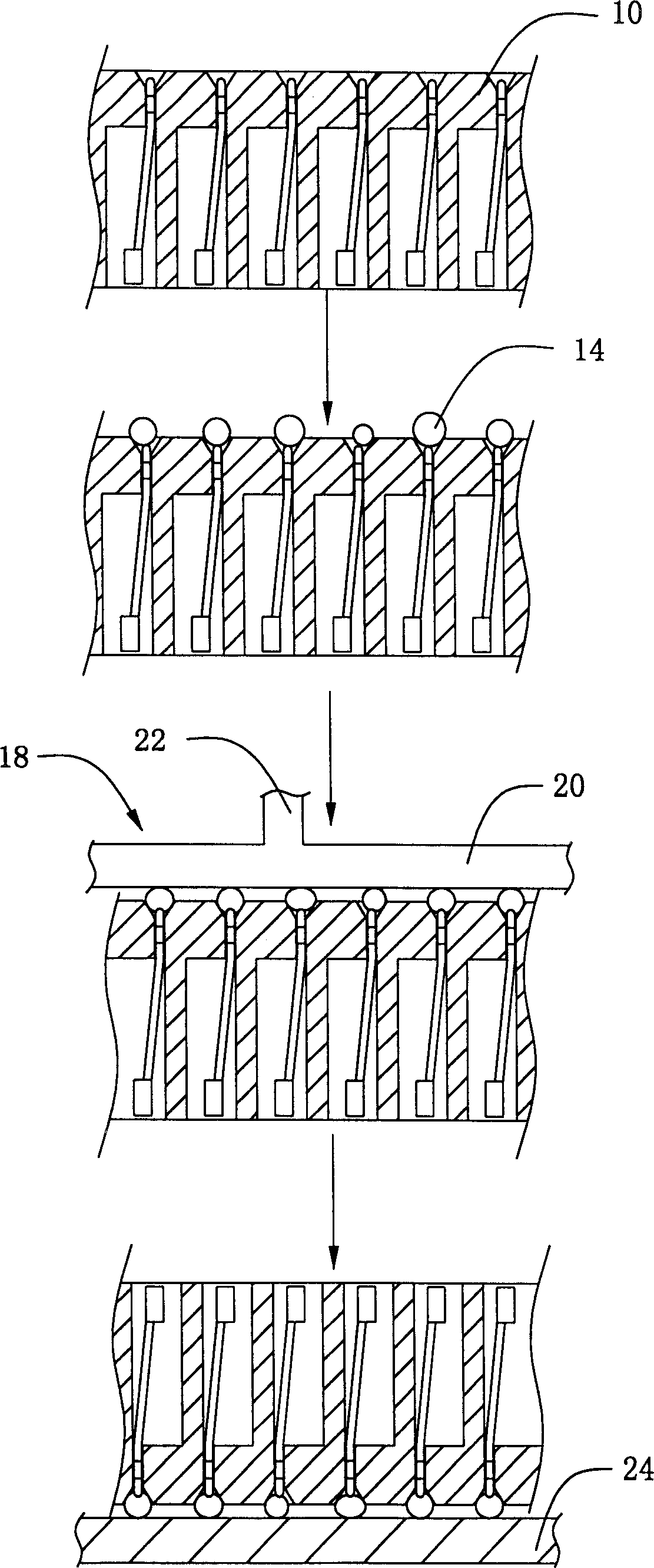

[0011] See figure 2 and image 3 It can be clearly seen that the steps of the present invention are as follows: step one is the pre-preparation process; step two is the solder ball planting process; step three is the flatness leveling process; step four is the welding process. Among them, the first step is to place the electronic component to be processed, such as the electrical connector or chip package 10, on the processing machine; the second step is to plant the solder ball 14 to one end of the conductive terminal 16 on the electrical connector or chip package 10 with a ball planting machine. ; Step three is to properly heat the solder ball 14 planted at one end of the conductive terminal 16 to a semi-molten state, and use the leveling tool 18 to add a pressure leveling step to it, the key part of the leveling tool 18 is a screed plate 20. The surface of the screed plate 20 in contact with the solder balls 14 has a high flatness; Step 4 is to flatten the electrical connector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com