Atomizing core, electronic cigarette and manufacturing method of atomizing core

A technology of atomizing core and atomizing liquid, which is applied in tobacco, smoker’s supplies, applications, etc. It can solve the problems of inconsistent speed, flow rate, unsmooth oil conduction, and easy carbon accumulation, so as to achieve uniform transmission and good user experience , the effect of reducing the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to understand the contents of the present invention, the following description should be used in conjunction with the accompanying drawings.

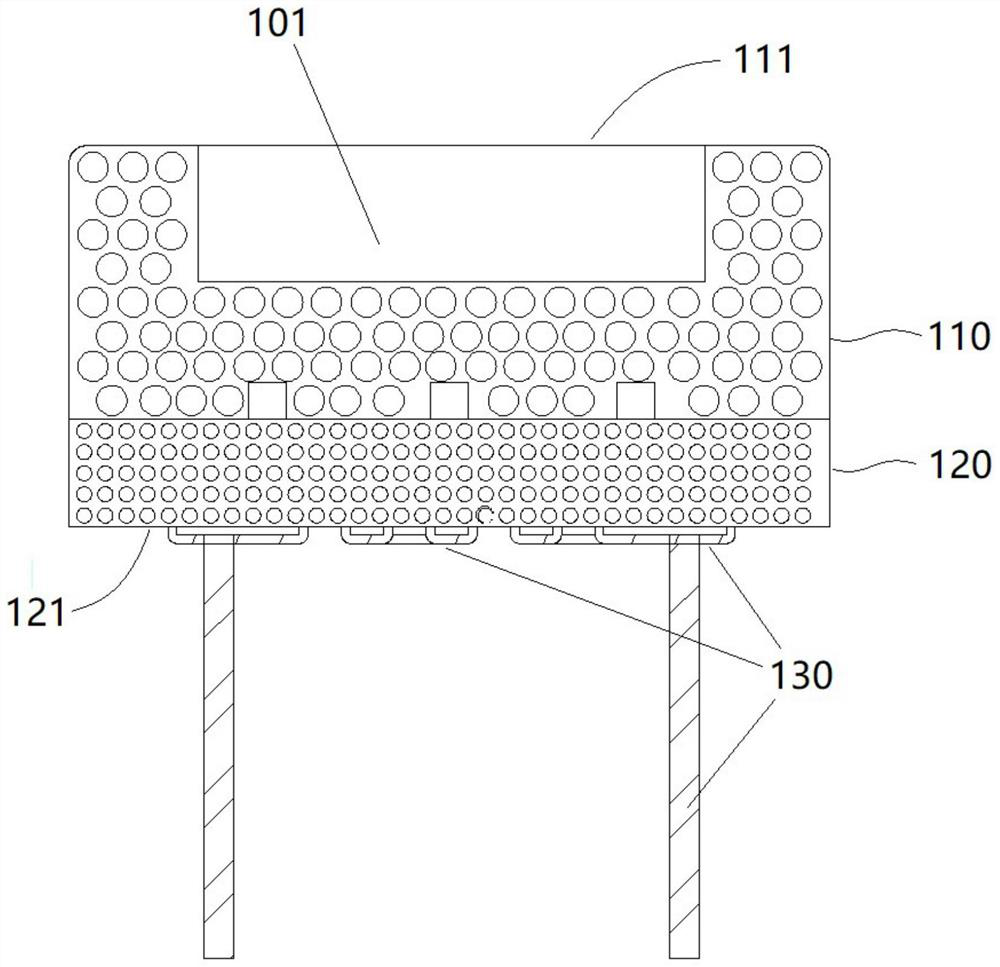

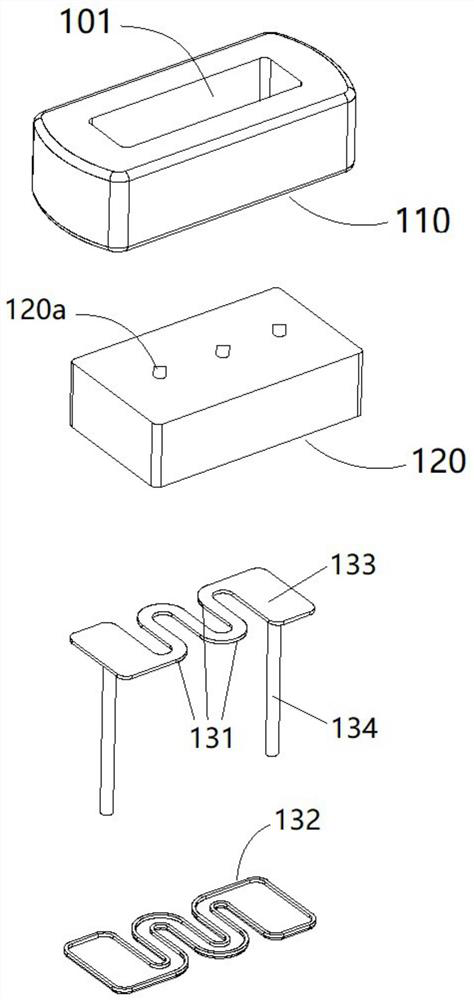

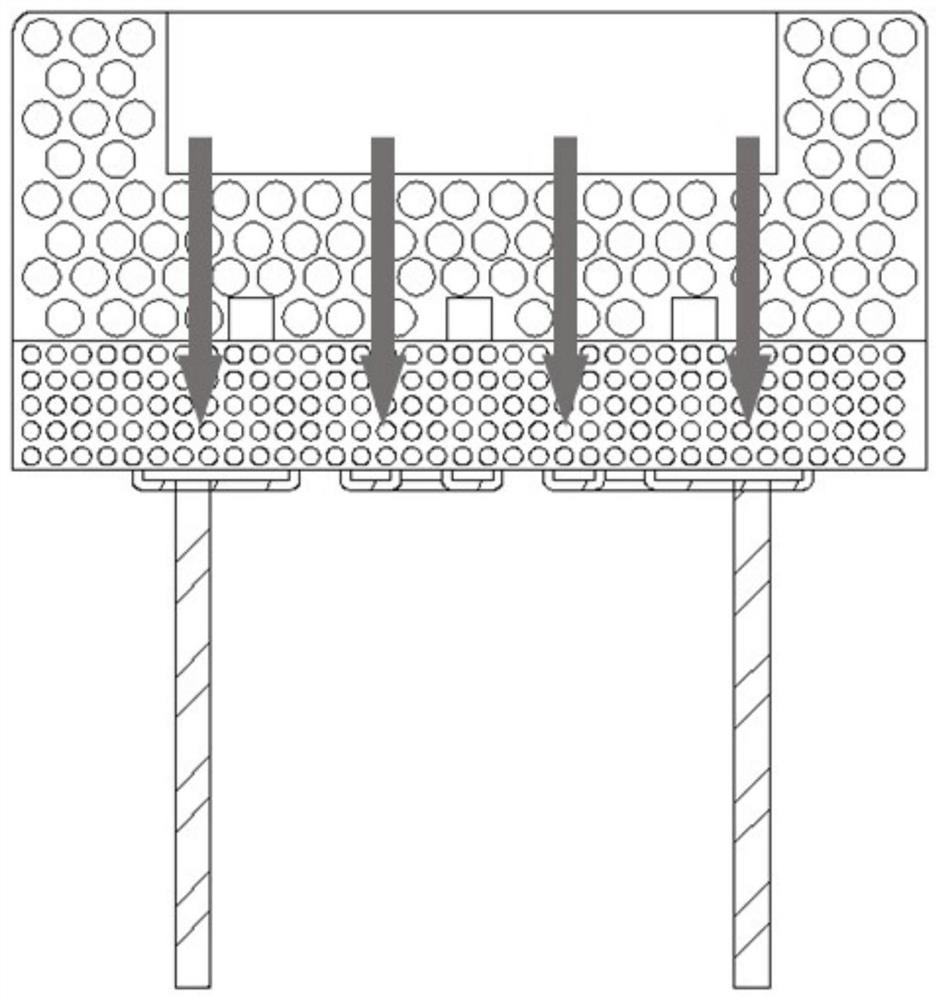

[0034] see figure 1 and figure 2 , an atomizing core according to an embodiment of the present invention, which is used in an electronic atomizer, includes a first guiding liquid 110 , a second guiding liquid 120 and an atomizing assembly 130 . The first guiding liquid 110 and the second guiding liquid 120 are both porous material bodies, and they abut to form a liquid suction channel. The porosity uniformity of the first conductive liquid 110 is greater than the porosity uniformity of the second conductive liquid 120 . The first guiding liquid 110 is used for contacting the atomized liquid. The atomization assembly 130 includes an energy conversion part, which is located on the second conductive liquid 120 and is isolated from the first conductive liquid 110 to atomize the atomized liquid absorbed by the second cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com