Screen body bending equipment for intelligent manufacturing of mobile phone liquid crystal display screen

A technology of intelligent manufacturing and mobile phone liquid crystal, which is applied in sorting and other directions, can solve problems such as poor bending accuracy, changes in bending points, white marks on the shaping screen, etc., and achieve the goal of eliminating secondary processing, easy bending, and avoiding breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

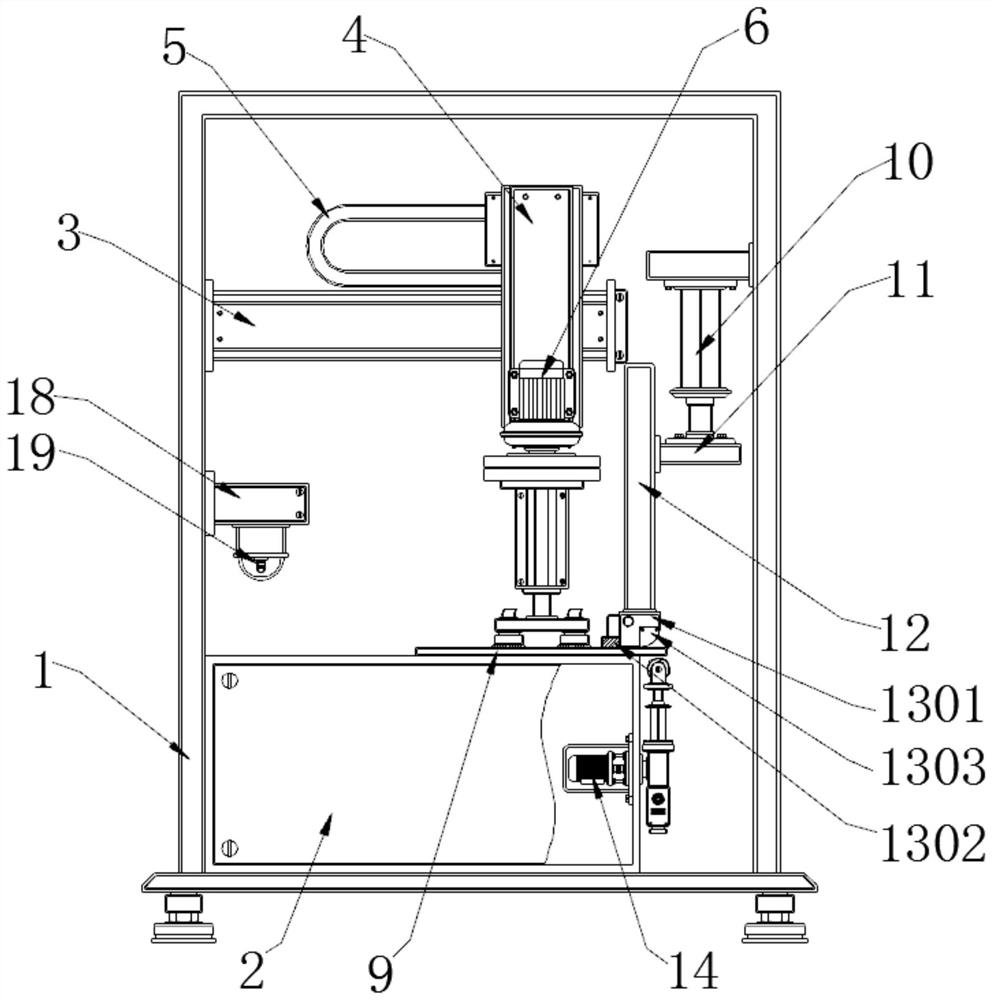

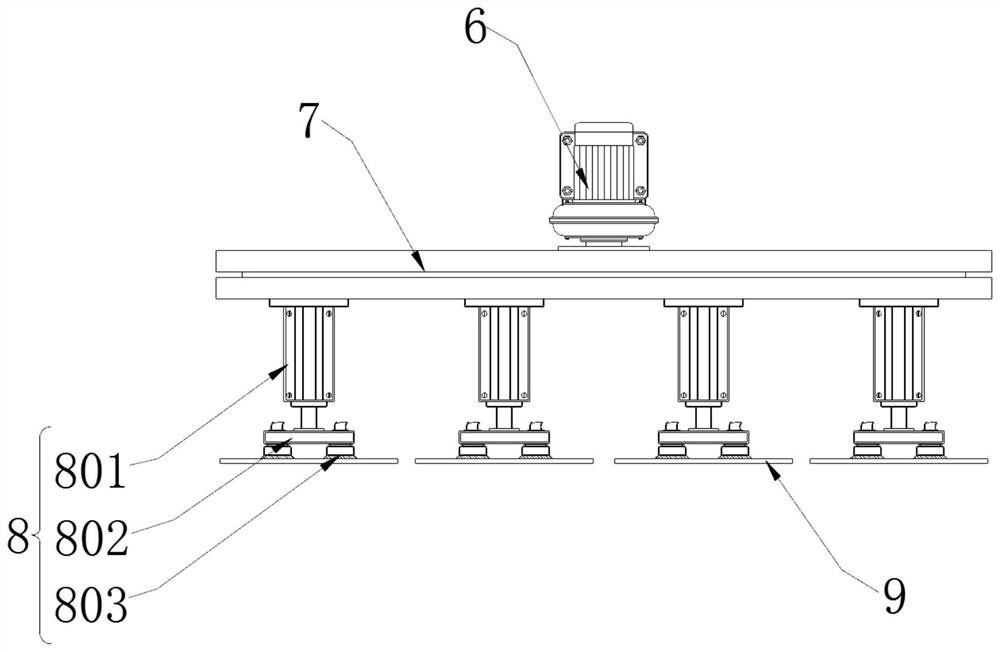

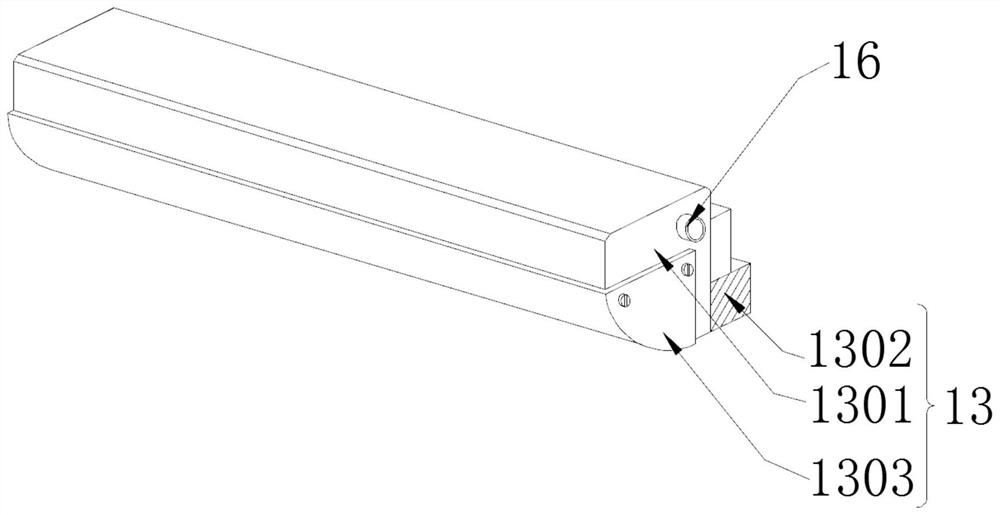

[0028] see Figure 1-6 , the present invention provides a technical solution: a screen bending device for intelligent manufacturing of liquid crystal display screens for mobile phones, including an outer frame body 1, a fixing component 8 and a forming component 13, and a processing table 2 is provided on the inner bottom of the outer frame body 1 , and the inner side of the top of the outer frame body 1 is provided with a traversing seat 3, the front outer side of the traversing seat 3 is provided with a moving vertical plate 4, and the top outer side of the moving vertical plate 4 is provided with a synchronous belt 5, and the moving vertical plate 4 A first motor 6 is arranged on the outer side of the front part, and a rotating seat 7 is arranged on the outer side of the bottom of the first motor 6, and a fixed assembly 8 is arranged on the outer bottom of the rotating seat 7, and a screen body 9 is connected to the outer side of the bottom of the fixed assembly 8. A first ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap