Energy-saving and environmental-friendly battery jar conveyor and working method thereof

An energy saving, environmental protection, conveyor technology, applied in conveyors, conveyor objects, circuits, etc., can solve the problems of large and difficult centralized charging, inability to flexibly use the volume of the conveyor, etc., to achieve flexible use, strong applicability, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

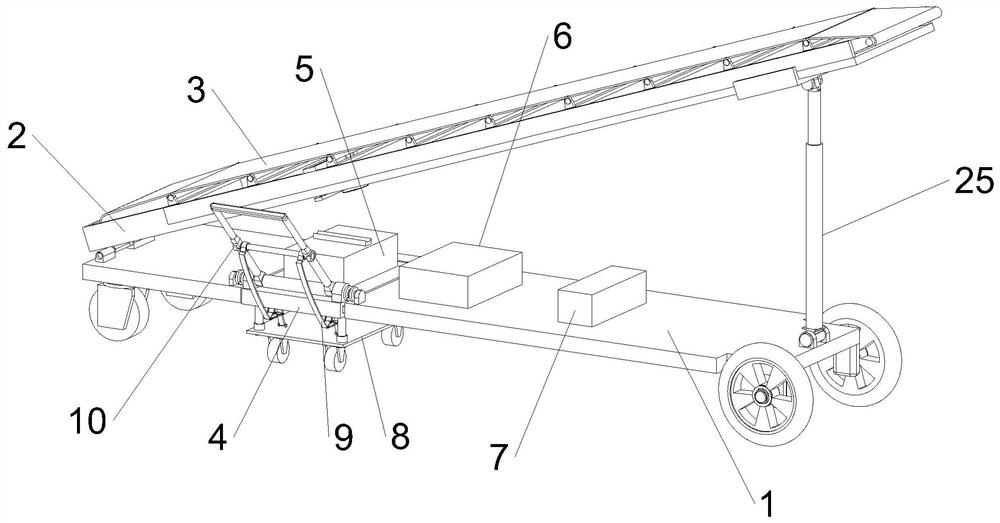

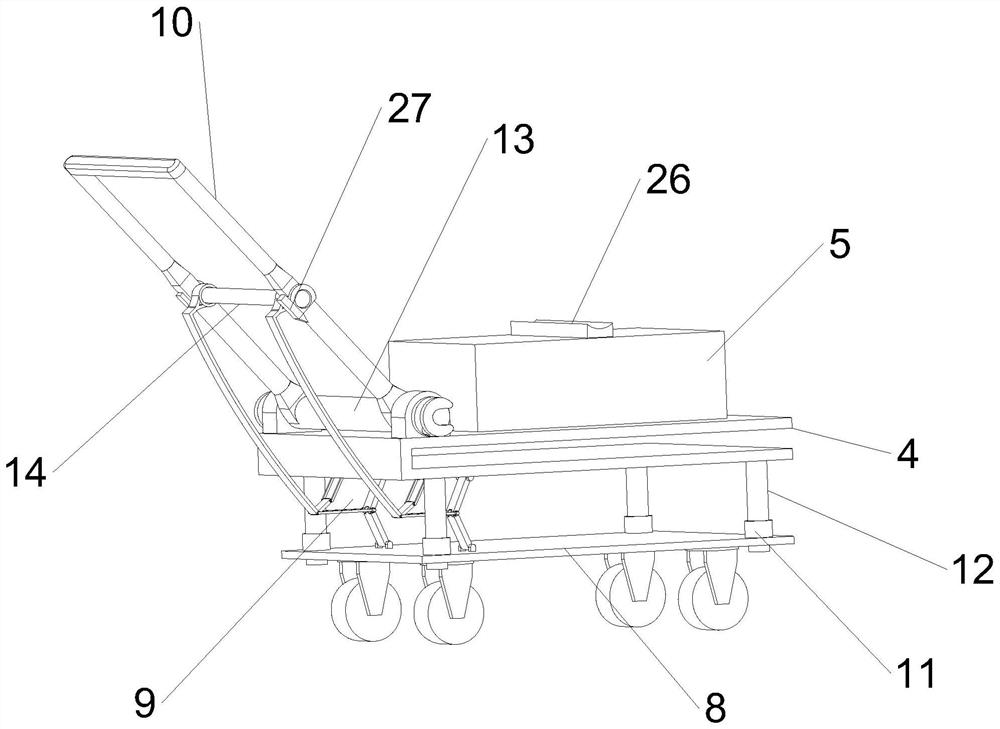

[0040] see Figure 1-Figure 2 As shown in the figure, an energy-saving and environment-friendly battery conveyor includes a bottom plate 1. Universal wheels are installed on the bottom of the bottom plate 1, and the universal wheels have a brake function. By stepping on the brakes, the universal wheels can be locked and fixedly transported. The position of the machine, the upper part of the bottom plate 1 is connected with the feeding plate 2, and the upper part of the feeding plate 2 is connected with the conveyor belt 3. The connection between the feeding plate 2 and the bottom plate 1 is through the oil cylinder 25. The oil cylinder 25 can be extended and then shortened. The output end of 25 is fixed on the lower surface of the loading plate 2, and the bottom end of the oil cylinder 25 can rotate on the base plate 1, and the oil cylinder 25 is driven by the hydraulic power box 7, and the hydraulic power box 7 is fixedly installed on the upper surface of the base plate 1, and...

Embodiment 2

[0043] The conveyor is powered by batteries. When charging the conveyor, a separate power battery box 5 is used, so that the battery box can be disassembled from the conveyor, so that the entire device does not need to be moved to the charging area when charging. convenient.

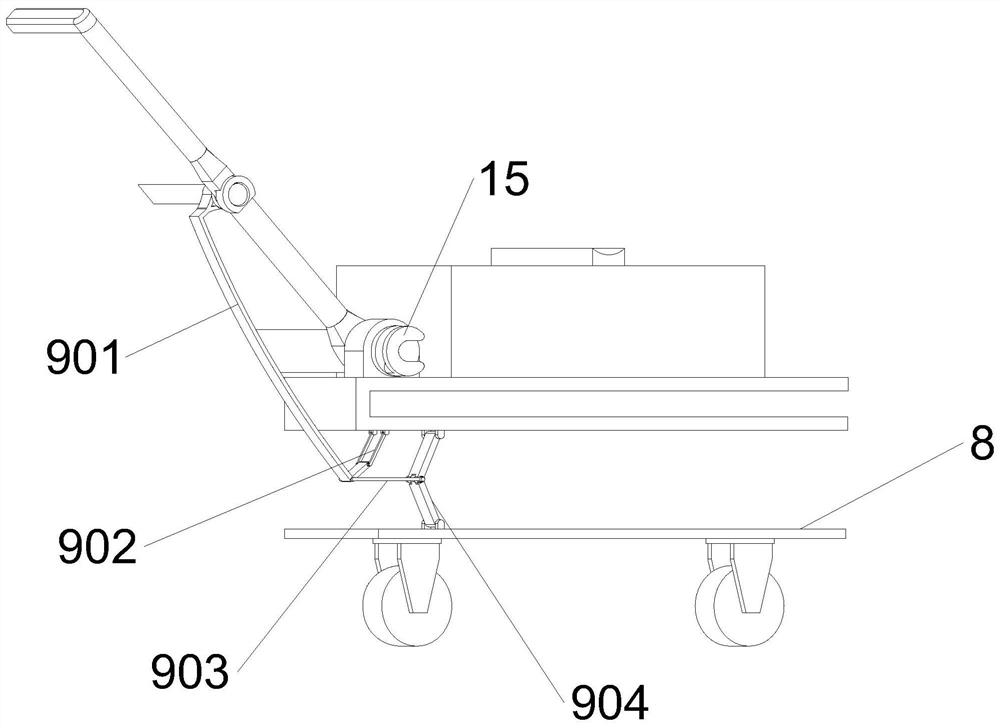

[0044] see Figure 2-Figure 3 As shown, the link mechanism 9 includes a control rod 901, a positioning rod 902, a connecting rod 903 and a support rod 904. The top of the control rod 901 is rotatably connected to the outer wall of the second connecting shaft 14. Rotate, the bottom of the control rod 901 is vertically provided with a cock, and the cocked end of the control rod 901 is rotatably connected with the positioning rod 902, so that the control rod 901 can rotate around the positioning rod 902 through the cocked end, and the top of the positioning rod 902 is rotatably connected to the clamp 4. On the lower surface, a connecting rod 903 is rotatably connected to the intersection of the bottom of t...

Embodiment 3

[0046] When the conveyor is working, it is inevitable that there will be debris flying and falling in the working area of the conveyor. If these debris are scattered on the power battery box 5 or the interface between the battery box and the power control cabinet 6, it will not only affect the power battery box 5 The heat dissipation effect will also affect the safety of the equipment during use. Therefore, a fan 24 is arranged above the power battery box 5 to clean and dissipate heat from the power battery box 5.

[0047] see Figure 6-Figure 9 As shown, the upper surface of the feeding plate 2 is connected with the rotating roller 17 through the base rotation, and the rotating roller 17 is fixed above the feeding plate 2 through the base, and the rotating roller 17 props up the conveyor belt 3 from the inside of the conveyor belt 3, so that the conveyor belt 3 can rotate smoothly One side of the base of the rotating roller 17 is fixedly equipped with a mounting seat 18, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com