A bionic self-repairing heat storage composite material and its preparation method

A composite material, self-healing technology, applied in the direction of heat exchange materials, chemical instruments and methods, ceramic products, etc., can solve the problems of composition segregation, affecting the performance and life of composite phase change heat storage materials, and achieve the purpose of alleviating segregation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further explained and illustrated below in the form of specific embodiments.

[0019] 1) Soak a polyurethane sponge with a pore size of 0.5-3mm in 20wt% NaOH solution for 2 hours.

[0020] 2) Immerse the polyurethane sponge in the ceramic slurry, make the slurry completely fill the inside of the sponge, and extrude the excess slurry. The thickness of the slurry attached to the surface of the sponge mesh is 0.2-0.5mm, and then it is statically dried for 24 hours to shape.

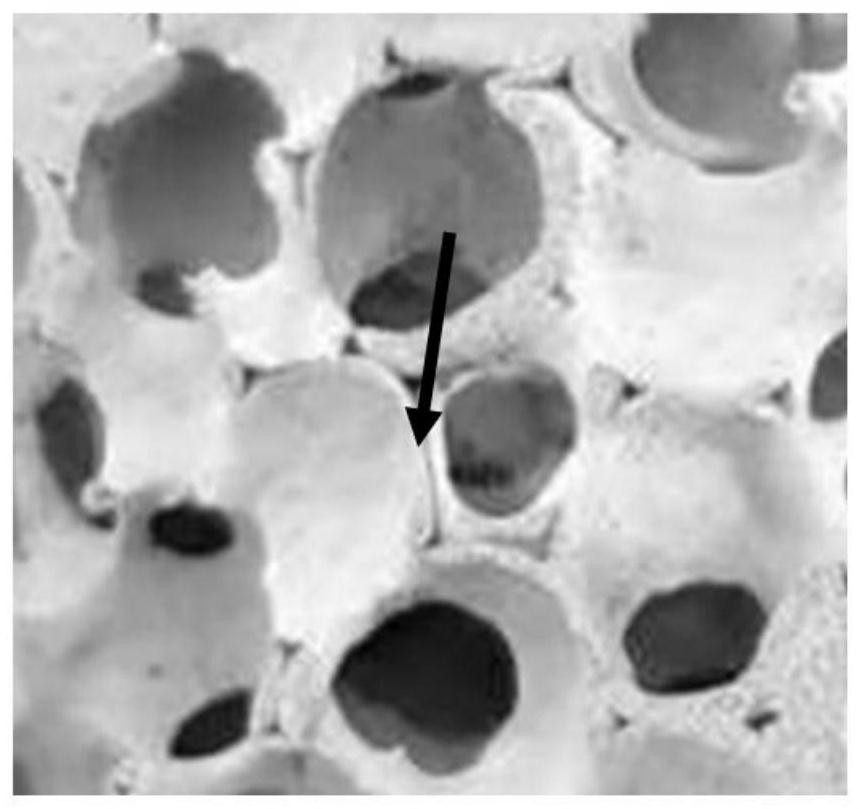

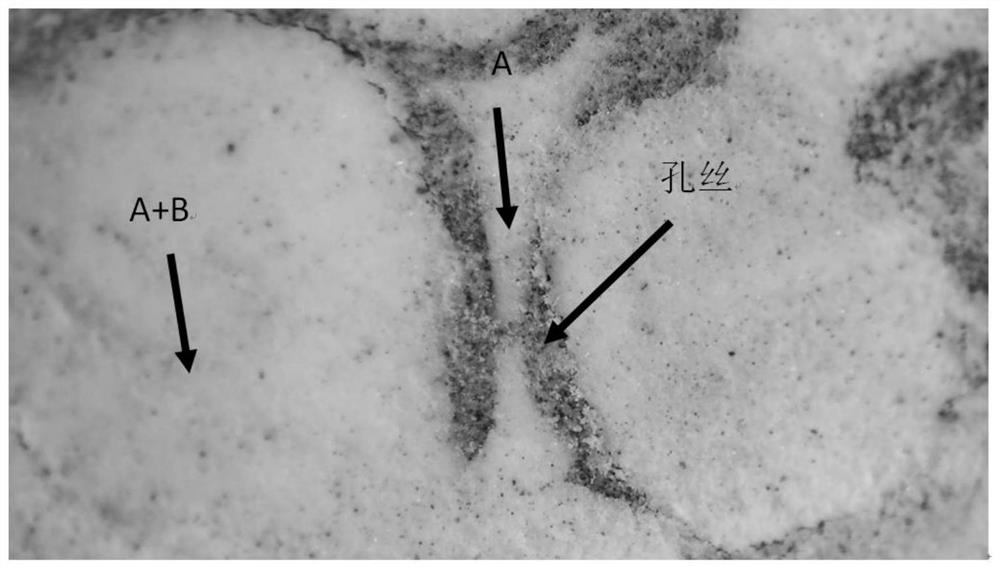

[0021] 3) Put the shaped foam into a high-temperature furnace, keep the temperature at 500-600°C for 2 hours, burn the polyurethane, and then continue to heat up to 1450°C and keep the temperature for 2 hours to obtain porous ceramics; the obtained porous ceramics have the following characteristics: a ) The three-dimensional structure of the void is the same as that of the polyurethane foam, which is an interconnected structure; b) the outer dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com