Chlorine-resistant color fixing agent based on polyethyleneimine structure and preparation method of chlorine-resistant color fixing agent based on polyethyleneimine structure

A technology of polyethylenimine and color-fixing agent, which is applied in dyeing, textiles and papermaking, can solve the problem of not significantly improving the fastness to chlorine bleaching and improve the fastness to chlorine bleaching and wet treatment , preventing migration and falling off, improving the color fastness to chlorine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

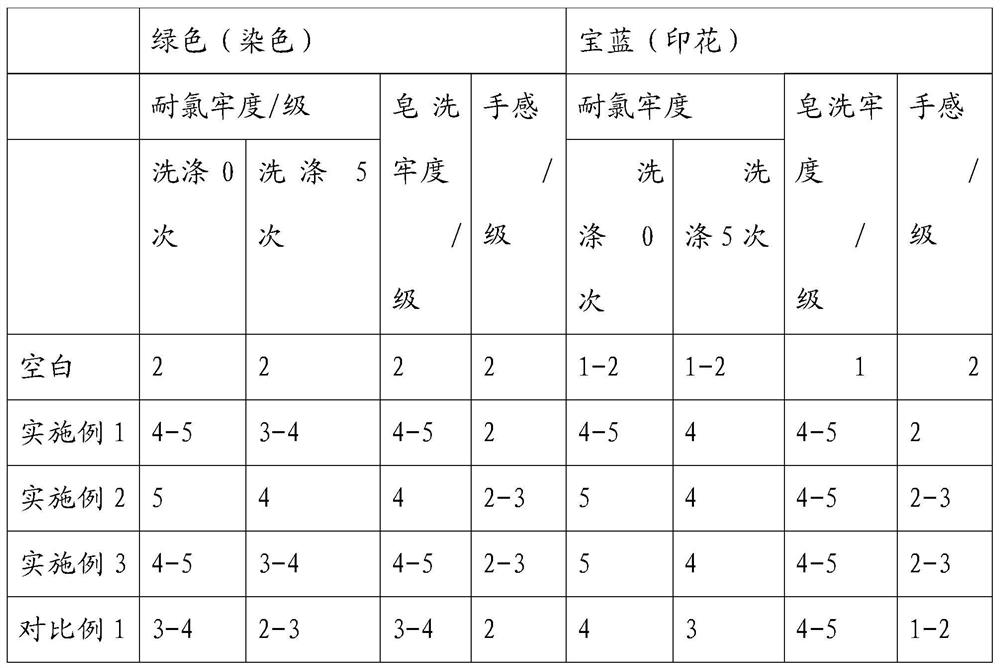

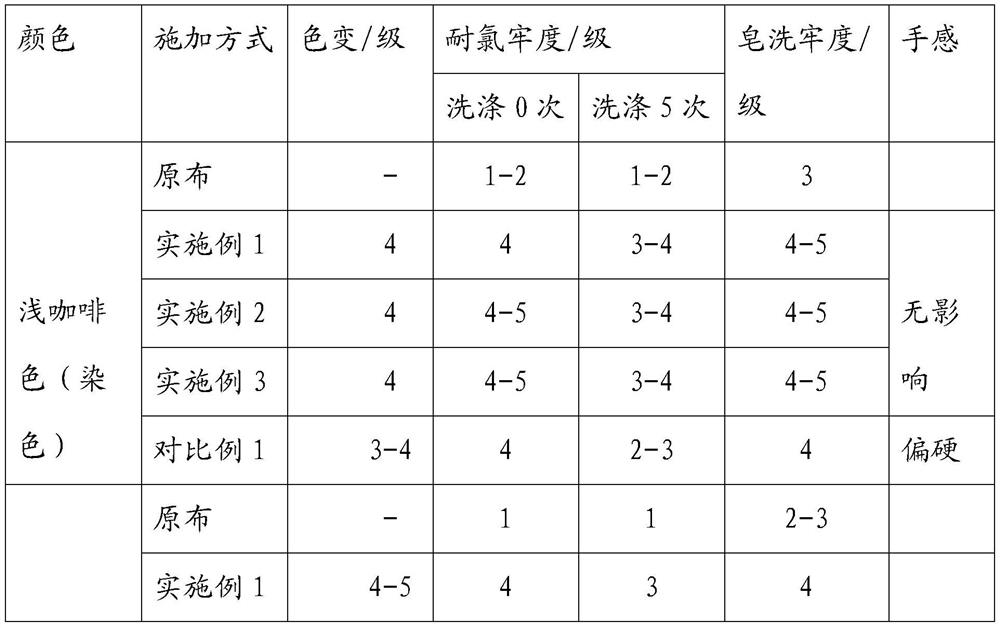

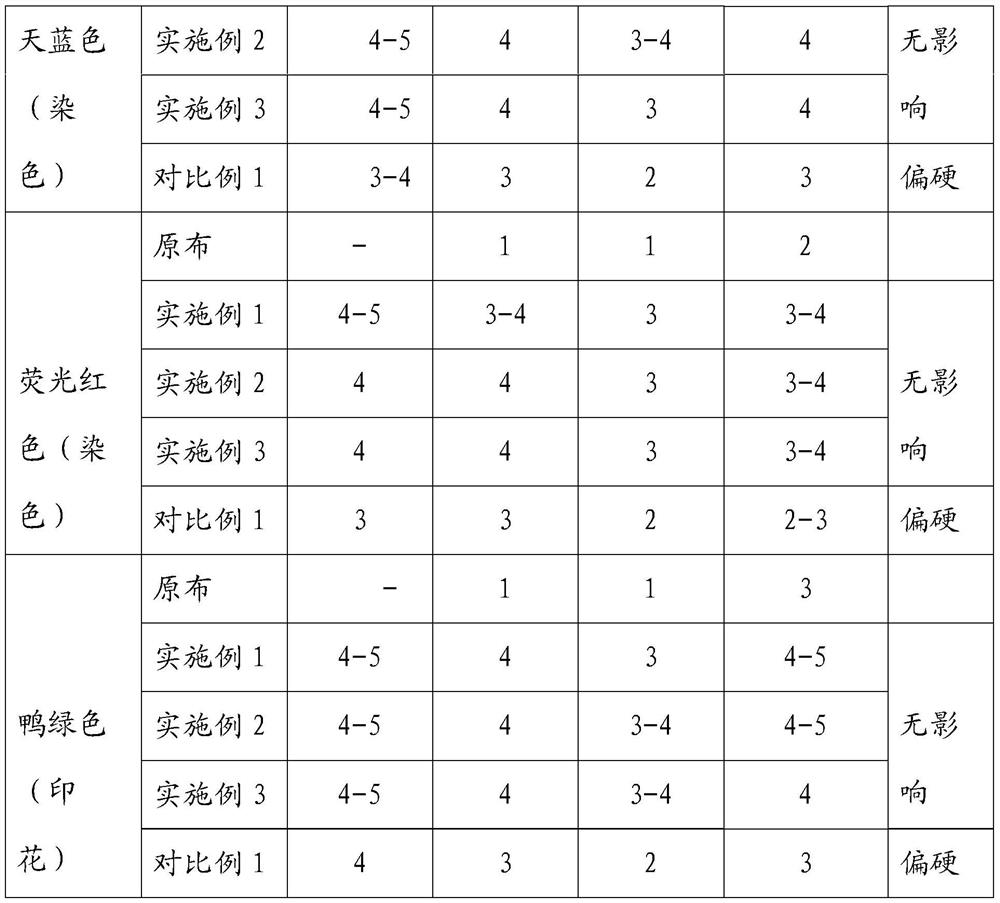

Examples

Embodiment 1

[0035] Preparation of acylated copolymer A:

[0036] Add 1 mol of polyethyleneimine to a reactor equipped with a stirrer, a thermometer, and a drop tank, add 2 mol of acryloyl chloride to the drop tank, cool with an ice-water bath and keep the temperature at 0-5°C), and Add acryloyl chloride dropwise while stirring at a stirring rate of 600-700 rpm. The dropwise addition time is 2 hours. After the dropwise addition, continue the reaction for 0.5 hour to obtain the acylated copolymer A1.

[0037] Preparation of chlorine-resistant color-fixing agent based on polyethyleneimine structure:

[0038] a. 0.7kg of ammonium persulfate is prepared with deionized water to an aqueous solution with a concentration of about 5%, and added to the head tank;

[0039] b. Add 10kg diallylamine hydrochloride in the reactor, during stirring, add 50kg dimethyl diallyl ammonium chloride;

[0040] c. Heating up to 40-45°C and adding 10kg of acylated copolymer A1, then rising to 76-78°C;

[0041] d....

Embodiment 2

[0044] Preparation of acylated copolymer A:

[0045]Add 1 mol of polyethyleneimine to the reactor equipped with a stirrer, a thermometer, and a drop tank, add 1 mol of acryloyl chloride to the drop tank, cool with an ice-water bath and keep the temperature at 0-5°C), and Add acryloyl chloride dropwise while stirring at a stirring rate of 600-700 rpm. The dropwise addition time is 1.5 h. After the dropwise addition, continue the reaction for 1.0 h to obtain the acylated copolymer A2.

[0046] Preparation of chlorine-resistant color-fixing agent based on polyethyleneimine structure:

[0047] a. 0.75kg of ammonium persulfate is prepared with deionized water to an aqueous solution with a concentration of about 5%, and added to the head tank;

[0048] b. add 10kg diallylamine hydrochloride in the reactor, during stirring, add 40kg dimethyl diallyl ammonium chloride;

[0049] c. Heating up to 40-45°C and adding 10kg of acylated copolymer A1, then rising to 76-78°C;

[0050] d. Us...

Embodiment 3

[0053] Preparation of acylated copolymer A:

[0054] Add 1 mol of polyethyleneimine to a reactor equipped with a stirrer, a thermometer, and a drop tank, add 3 mol of acryloyl chloride to the drop tank, cool with an ice-water bath and keep the temperature at 0-5°C), and Add acryloyl chloride dropwise while stirring at a stirring rate of 600-700 rpm. The dropwise addition time is 2.3 hours. After the dropwise addition, continue the reaction for 0.2 hours to obtain the acylated copolymer A3.

[0055] Preparation of chlorine-resistant color-fixing agent based on polyethyleneimine structure:

[0056] a. 0.65kg of ammonium persulfate is prepared with deionized water to an aqueous solution with a concentration of about 5%, and added to the head tank;

[0057] b. Add 10kg diallylamine hydrochloride in the reactor, during stirring, add 50kg dimethyl diallyl ammonium chloride;

[0058] c. Warm up to 40-45°C and add 12.5kg of acylated copolymer A3, then rise to 76-78°C;

[0059] d. U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com