High-elasticity breathable textile material and production and preparation process thereof

A technology for textile materials and preparation processes, which is applied in the directions of vibrating liquid/gas/vapor removal with textile materials, liquid/gas/vapor fabric processing, metal processing, etc. Inaccurate hole position and other problems, to achieve the effect of reducing the number of workers, reducing the amount of work, and improving the firmness of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

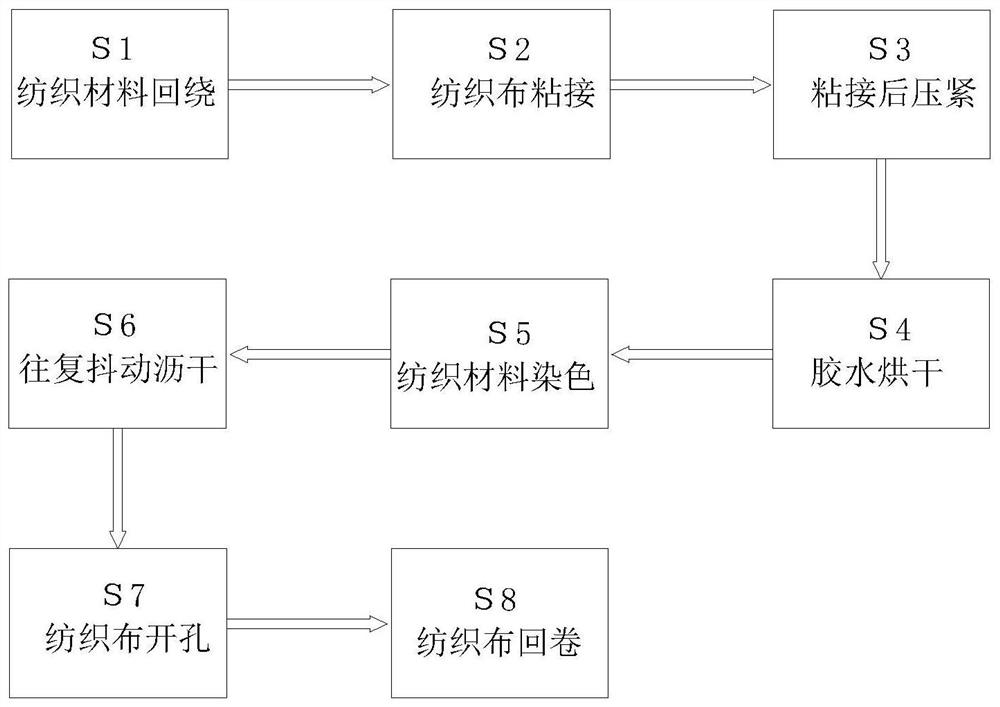

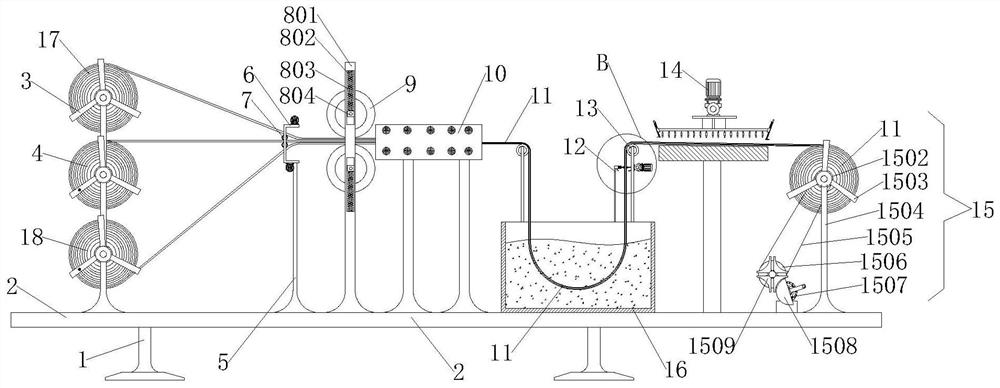

[0055] see Figure 1-9 It is a schematic diagram of the overall structure of a high elastic breathable textile material and the production and preparation process of the high elastic breathable textile material;

[0056] A production and preparation process of a high elastic breathable textile material is characterized in that it comprises the following steps:

[0057] S1 textile material rewinding: rewinding the multi-layer textile fabric, so that the textile fabric of different materials wound into a cylinder is stretched in one direction at the same time;

[0058] S2. Bonding of textile cloth: laminating and bonding the multi-layer textile materials in step S1, and pasting and fastening the textile cloth wound into a cylindrical shape by different materials;

[0059] S3. Compression after bonding: In step S2, the multi-layer textile cloth is interlayer pasted and fixed, and then compacted and fixed. Two pressure rollers are rolled and compacted from the middle of the texti...

Embodiment 2

[0093] read on Figure 1-9It is a high-elastic and breathable textile material. This embodiment has similarities with the above-mentioned embodiment 1, and the similarities will not be described in this embodiment. The specific differences are:

[0094] A high-elastic and breathable textile material, comprising a textile cloth 4, a first pasting cloth 17, and a second pasting cloth 18, the textile cloth 4 is arranged in the middle layer, the top layer of the textile cloth 4 is bonded with the first pasting cloth 17, and the top layer of the textile cloth 4 A second pasting cloth 18 is bonded, and the textile cloth 4 is made of cotton; the first pasting cloth 17 and the second pasting cloth 18 are non-woven fabrics with rhombus mesh.

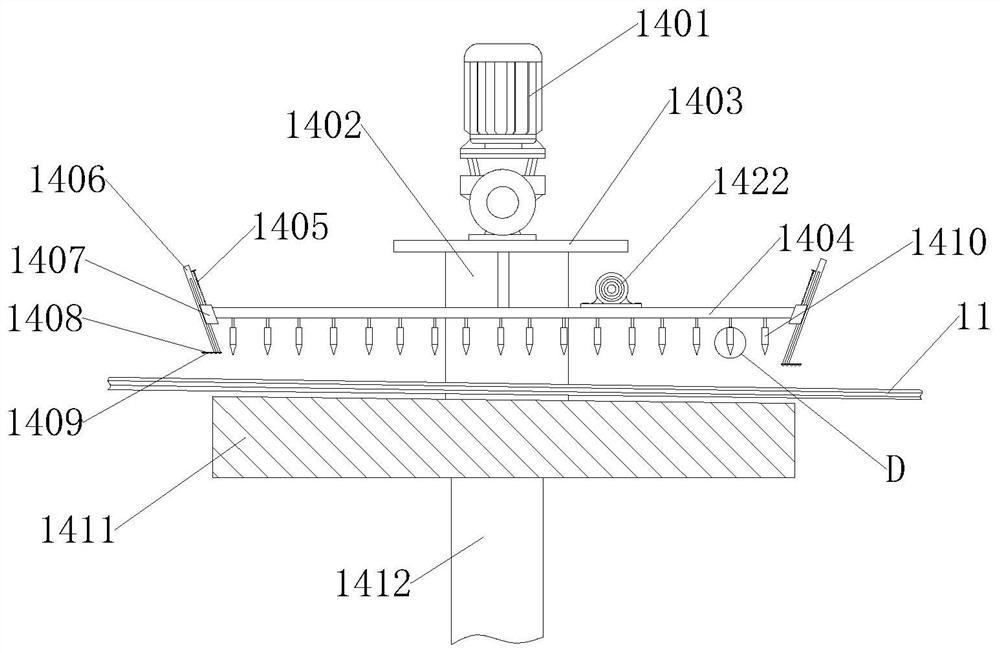

[0095] The cloth shaking mechanism 12 includes a third support rod 1211 upright and fixed on the top of the dyeing box 16, a second electric push rod 1210 is fixedly installed in the middle of the third support rod 1211, and a push rod is stretch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com