Intelligent formed textile product continuous drying device and method

A textile product and drying device technology, which is applied in the field of textile production, can solve the problems of taking a long time, reducing the practicality of the device, and having too many guide rollers, so as to improve the drying effect and drying efficiency, ensure the aesthetics, The effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

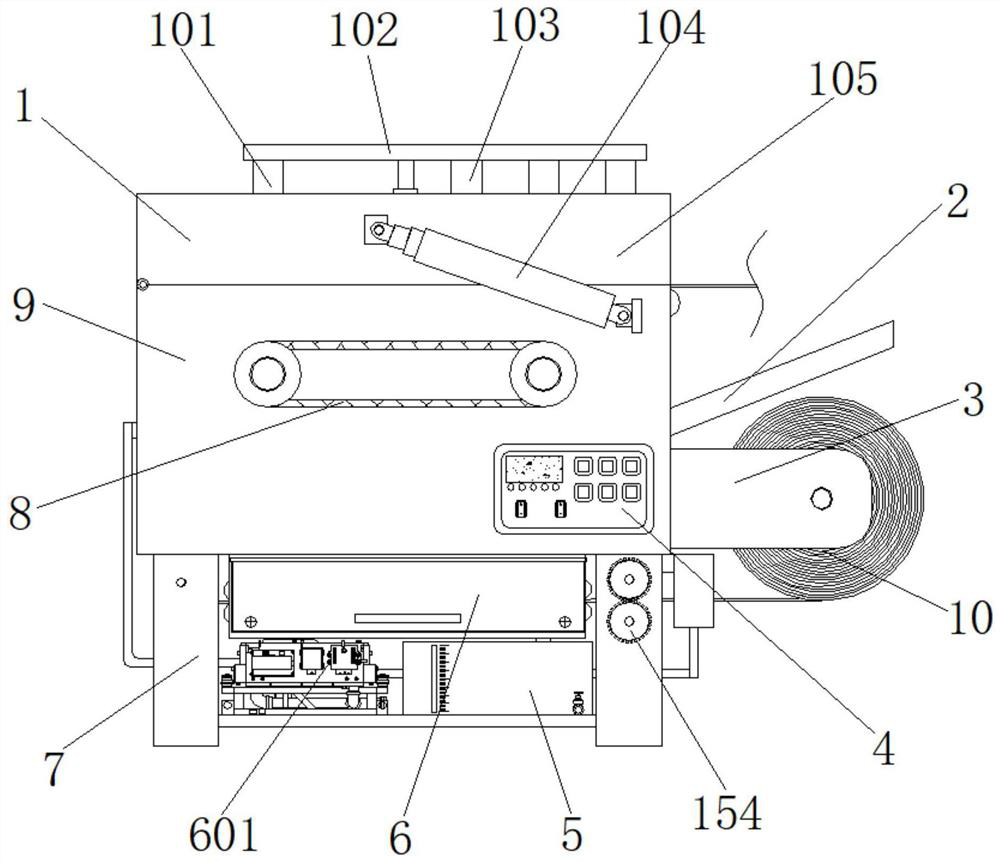

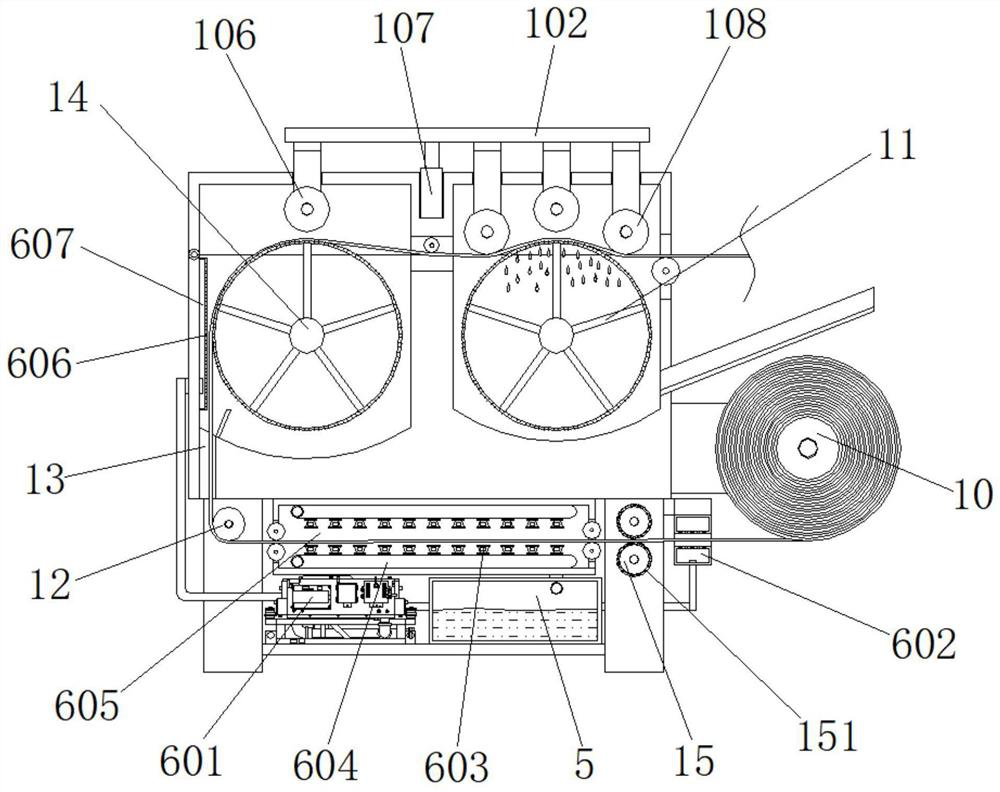

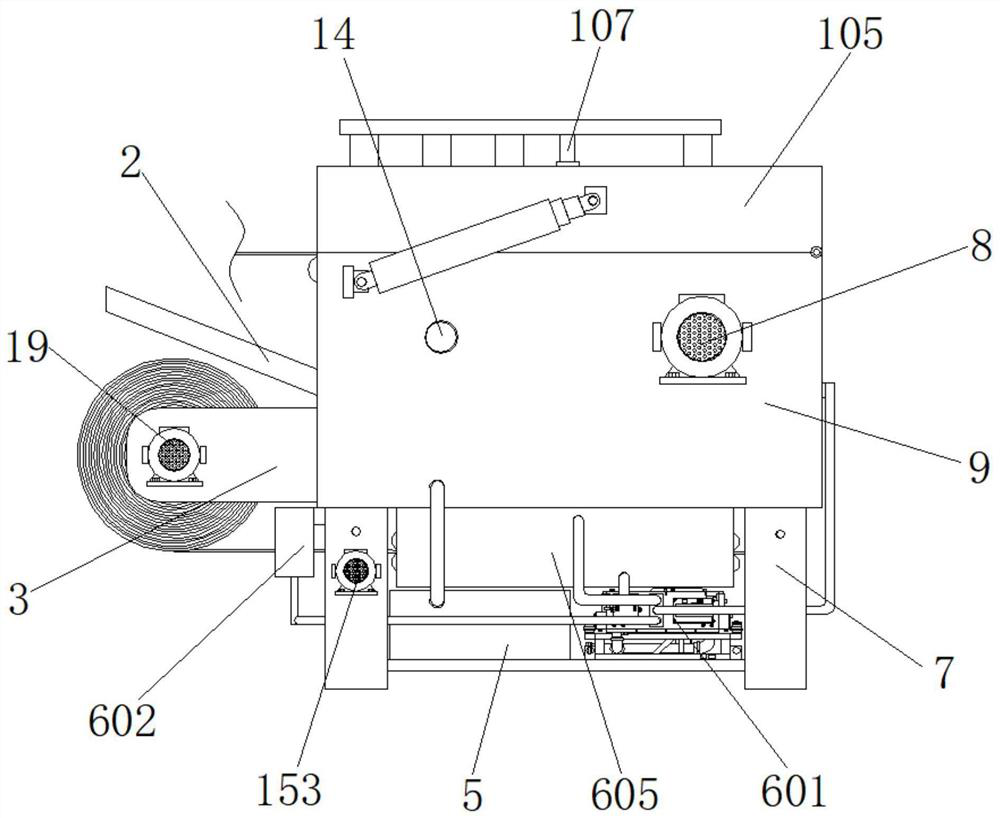

[0050] Example 1, such as Figure 1-6 As shown, when the molded textile product needs to be bypassed inside the device, the electric push rod 104 is first controlled to extend through the control panel 4, so that the cover bin 105 is gradually opened by its hinge shaft, and then the molded textile product is manually laid on both sides. Group the top of the screen cylinder 18, then pass the head end of the formed textile product through the strip-shaped through hole 13 and then pass through the steering guide roller 12 and enter the inside of the drying chamber 605, and then pass the formed textile product through two sets of installation rollers 152 Finally, the head end of the formed textile product is fixed on the outside of the winding roller 10 after passing through the annular hollow chamber 602, and the cover chamber 105 is controlled to be re-covered on the top of the main chamber 9, and then the electric lifting rod 107 is controlled to shorten, so that the first guide...

Embodiment 2

[0051] Example 2, such as Figure 1-8As shown, when starting to dry the formed textile product, then control the second driving motor 19 to drive the winding roller 10 to start winding the formed textile product, and control the driving device 8 to drive the two groups of rotating shafts 14 to rotate, that is, control the two groups of The screen cylinders 18 rotate synchronously and in the same direction, so that the formed textile products pass through the interior of the device at a constant speed. The water is extruded, and the extruded water droplets pass through the sieve holes on the surface of the first group of sieve cylinders 18 and gradually gather to the inner bottom of the processing chamber 17, and flow into the interior of the collection chamber 5 through the pipeline, and then the extruded formed textile products When passing through the outside of the second group of screen cylinders 18, the hot air blower 601 is controlled to deliver the hot air to the inside...

Embodiment 3

[0052] Example 3, such as figure 1 , 2 , 3, 4, 5 and 9, when it is necessary to ensure the compliance of the fluff on the surface of the formed textile product, the first driving motor 153 is controlled to drive a group of installation rollers 152 to rotate, and the two groups of installation rollers 152 pass through the rotation of two groups of gears 154 transmission, so that the two sets of installation rollers 152 rotate in opposite directions, use the bristles 151 on the outside of the installation rollers 152 to brush the fluff on the surface of the formed textile product, and then cooperate with the hot air blown obliquely from the second air outlet 608, which greatly ensures the formation of textile products. The softness of the fluff on the surface of the product ensures the aesthetics of the formed textile product.

[0053] Working principle: connect the device to the power supply before use, and when it is necessary to bypass the inside of the device, the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com