A kind of pcb solder mask window opening automatic processing method

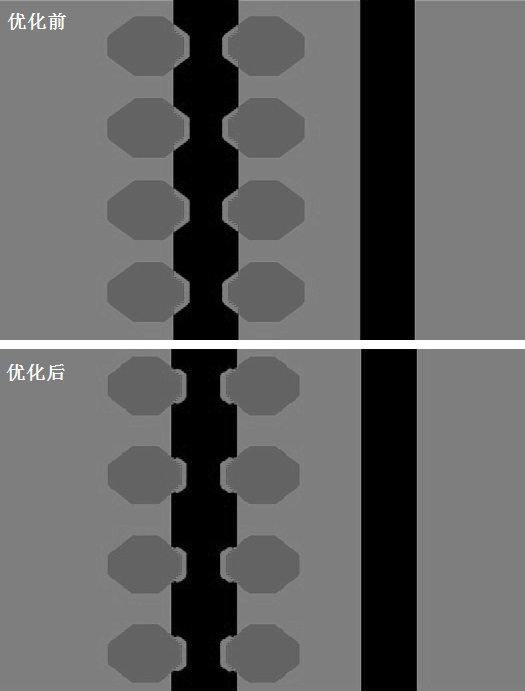

A technology of automatic processing and window opening, which is used in electrical digital data processing, special data processing applications, CAD circuit design, etc. Problems such as poor efficiency, to avoid the tombstone effect, avoid the size of the tin receiving area, and ensure the effect of the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate those skilled in the art to understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

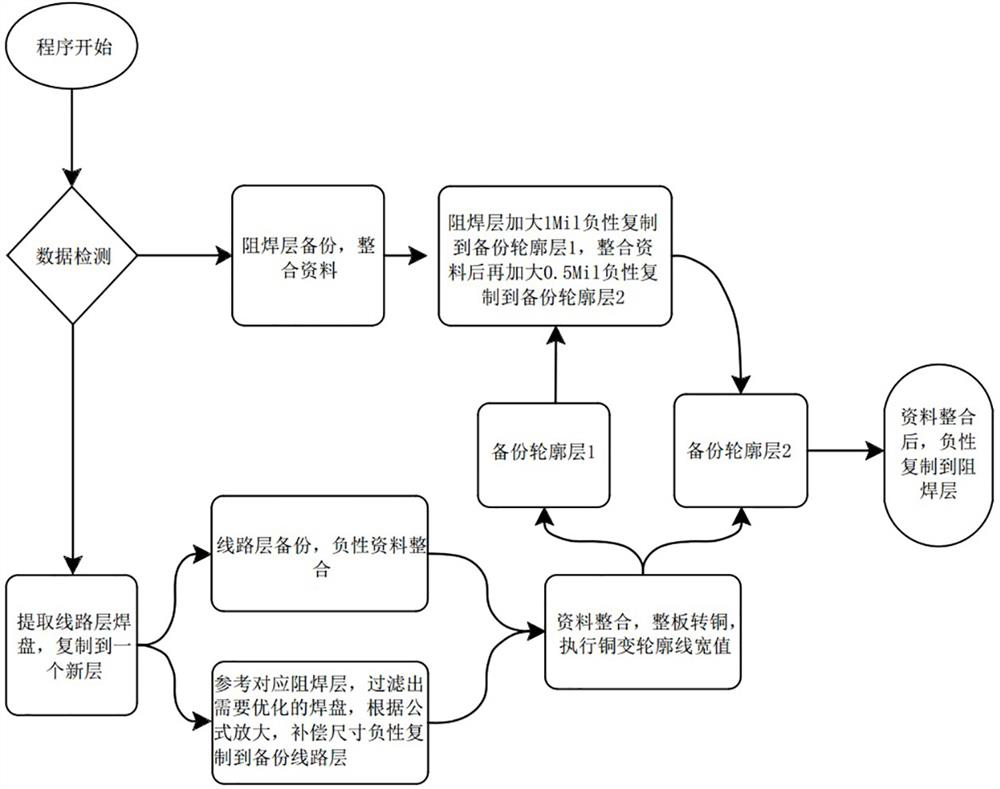

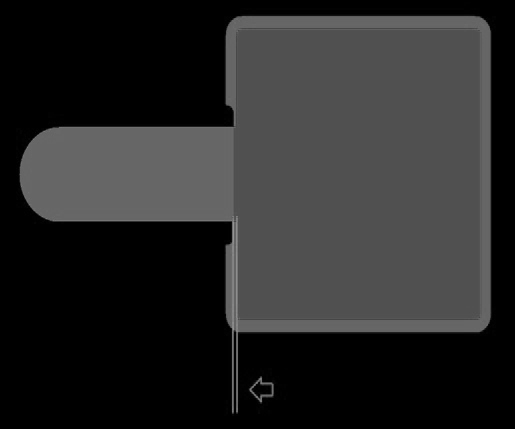

[0032] refer to Figure 1 to Figure 6 , the present invention provides an automatic processing method for PCB solder resist window opening, comprising: checking and extracting the data of both the circuit layer and the solder resist layer, and duplicating and backing up the data of the two, and screening out the solder that needs to be optimized according to the data. Disk, copy the data of the pads that need to be optimized in the circuit layer to the backup of the circuit layer data, and integrate the positive and negative data to obtain the backup contour layer, optimize the data of the backup contour layer, and save the optimized The backup contour layer and the backup of the solder mask layer are negatively superimposed to complete the solder mask op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com