Method for determining dosage of coating material in modification treatment of coral aggregate and modification method

A technology for cladding materials and determining methods, which is applied in the field of civil engineering and construction materials, can solve problems affecting performance, affecting maintenance, and difficult to accurately determine, and achieve uniform coating, guaranteed coating treatment effect, and high coincidence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

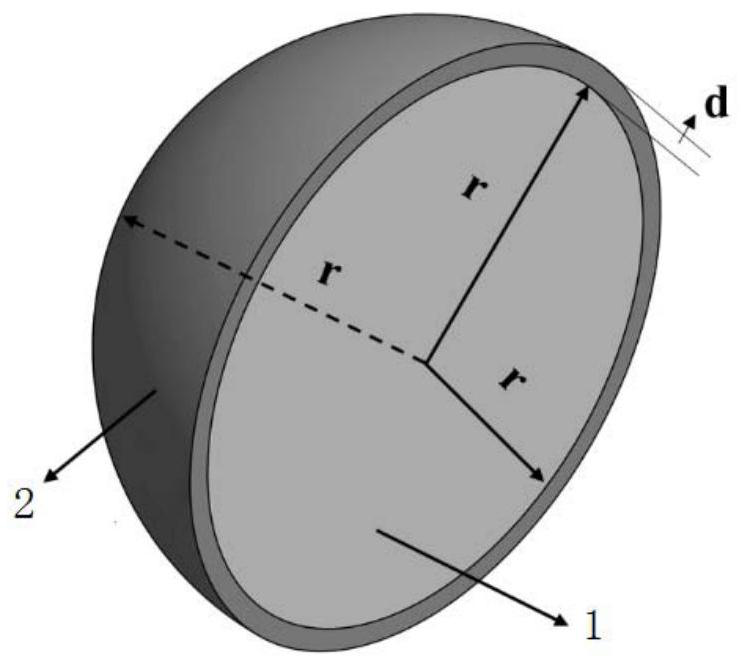

Image

Examples

Embodiment 1

[0084] This embodiment provides a modification method of coral aggregate, and the specific steps are as follows:

[0085] Dosage of coating material

[0086] 1, screening points, 100kg coral aggregate sieves are 25kg having a particle size of 4.75-9 mm; 50 kg having a particle size of 9.5-16mm; 25 kg having a particle size of 16-19mm;

[0087] 2. Determine the value of each parameter in the calculation formula: Test the density of the slurry material used to treat coral aggregates, the present embodiment is used as a cement-based mixture of 0.47 as a coating material, and the density ρ is tested. p 2000kg / m 3 The loose stacking density of the coral aggregates is 973kg / m in turn. 3 965kg / m 3 ; 954kg / m 3 The thickness of the coating layer is 1 mm;

[0088] 3. The total coating material required for coral aggregates by grading is calculated from the grading average particle diameter, and the total amount of coated material is 55.8 kg.

[0089] Modification treatment

[0090] ...

Embodiment 2

[0093] This embodiment provides a modification method of coral aggregate, and the specific steps are as follows:

[0094] The first step: Screening, in Example 1.

[0095] Step 2: The coating material is equipped with Example 1, and the cladding layer thickness is selected for 2mm;

[0096] In the third step: According to the grading average particle diameter, the coated material required for each stage of screening is calculated, and the total amount of coating material is used in total is 111.6 kg.

[0097] Step 4: Take 100kg of coral sand, 111.6 kg of coated material is taken.

[0098] Step 5: Add coral sand in the mixer, first add a good water, stir 120s, to get the intermediate, then slowly add the powder while stirring, continue to stir 3 min, discharge, stack, and maintain 16 h at room temperature, Modified coral aggregate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com