Preparation method of alkaline fuel cell exchange membrane

A technology of fuel cells and exchange membranes, applied in the field of exchange membranes, to achieve high conductivity, ensure alkali stability, and excellent alkali stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of an alkaline fuel cell exchange membrane, specifically comprising the steps of:

[0025] S1: Place polyphenylene ether (PPO) in an oven at 100°C for 10 minutes to dry, then take it out of the oven, and let it cool to room temperature.

[0026] S2: Put the polyphenylene ether dried in step S1 into a three-necked round-bottomed flask, add chlorobenzene and magneton, wherein the molar ratio of PPO to chlorobenzene is 1:1.2, in order to prevent bumping, add zeolite, and turn on the magnetic stirring Switch on and off at 40°C to make the PPO fully dissolved by magnetic stirring.

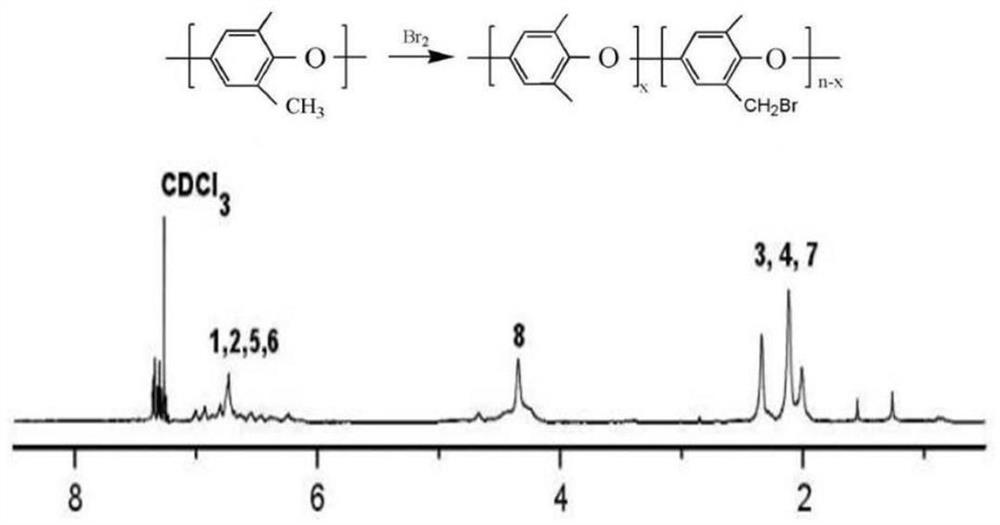

[0027] S3: Dilute liquid bromine with chlorobenzene to obtain a solution, then add it to the dropping funnel, place the dropping funnel on the three-neck round bottom flask in step S2, and slowly add it to the uniformly dissolved polyphenylene ether solution for bromination reaction , wherein the nitrogen gas was continuously fed during the whole reaction process, first reac...

Embodiment 2

[0033] A preparation method of an alkaline fuel cell exchange membrane, specifically comprising the steps of:

[0034] S1: Place the polyphenylene ether (PPO) in an oven at 100°C for 30 minutes to dry, then take it out of the oven, and let it cool to room temperature.

[0035] S2: Put the polyphenylene ether dried in step S1 into a three-necked round-bottomed flask, add chlorobenzene and magneton, wherein the molar ratio of PPO to chlorobenzene is 1:2, in order to prevent bumping, add zeolite, and turn on the magnetic stirring Switch on and off at 50°C to make the PPO fully dissolved by magnetic stirring.

[0036] S3: Dilute liquid bromine with chlorobenzene to obtain a solution, then add it to the dropping funnel, place the dropping funnel on the three-neck round bottom flask in step S2, and slowly add it to the uniformly dissolved polyphenylene ether solution for bromination reaction , in which nitrogen gas was continuously fed during the whole reaction process, first react...

Embodiment 3

[0042] A preparation method of an alkaline fuel cell exchange membrane, specifically comprising the steps of:

[0043] S1: Place polyphenylene ether (PPO) in an oven at 100°C for 20 minutes to dry, then take it out of the oven, and let it cool to room temperature.

[0044] S2: Put the polyphenylene ether dried in step S1 into a three-necked round-bottomed flask, add chlorobenzene and magneton, wherein the molar ratio of PPO to chlorobenzene is 1:1.5, in order to prevent bumping, add zeolite, and turn on the magnetic stirring Switch on and off, at 45°C, let the magnetic sub-stirring PPO fully dissolve.

[0045] S3: Dilute liquid bromine with chlorobenzene to obtain a solution, then add it to the dropping funnel, place the dropping funnel on the three-neck round bottom flask in step S2, and slowly add it to the uniformly dissolved polyphenylene ether solution for bromination reaction , in which nitrogen gas was continuously fed during the whole reaction process, first reacted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com