Washable efficient anti-mite agent and preparation method thereof

An anti-mite and water-resistant technology, applied in the fields of botanical equipment and methods, acaricides, biocides, etc. the effect of folds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

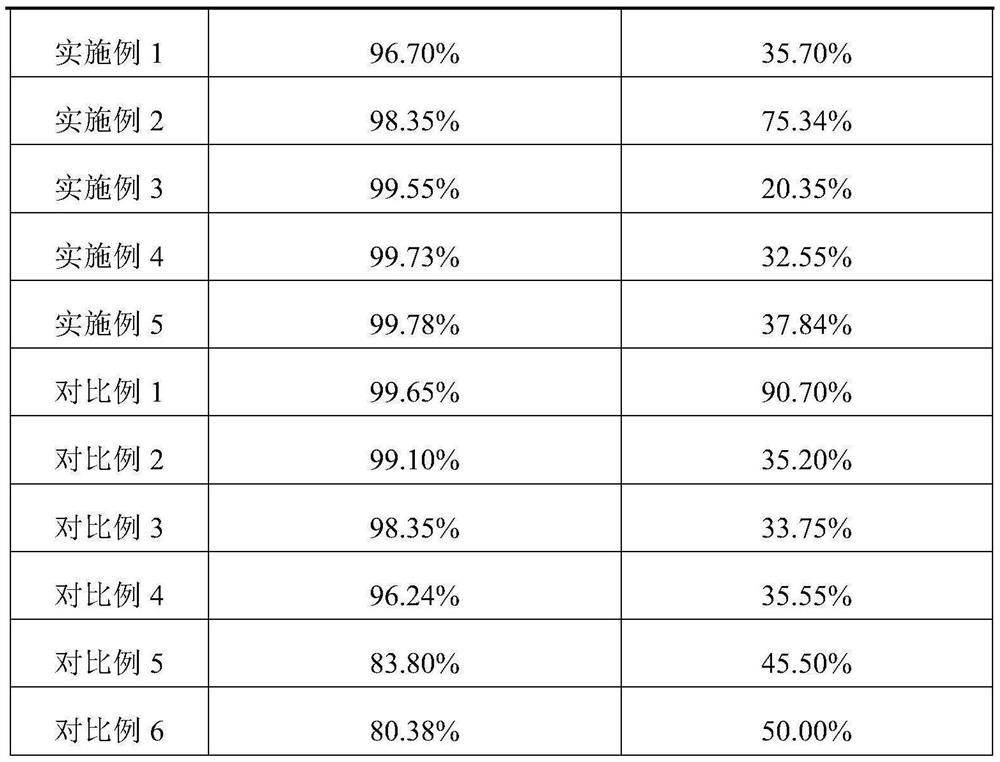

Embodiment 1

[0033] A washable and efficient anti-mite agent prepared from the following raw materials:

[0034] Acaricidal ingredient: 1.3%, repellent ingredient: 2.2%, dispersant 0.3%, emulsifier 0.5%, wall material 3%, buffer 4%, initiator 0.3%, coagulant 1.5%, and the rest is absolute ethanol, Deionized water.

[0035] The preparation method comprises the following steps:

[0036] First add the acaricidal component, repellent component, dispersant, and deionized water into the beaker, heat it in a water bath for 60 minutes to 80°C, then keep it at a constant temperature of 60°C and stir for 40 minutes at a stirring speed of 300r / min, then add in sequence Continue to stir the wall material, coagulant, initiator and absolute ethanol, raise the temperature to 80°C and react for 1.2h, then add an emulsifier and continue stirring for 1h to make the wall material and core material emulsify evenly, and finally add a buffer to adjust the pH of the solution to 7. A high-efficiency anti-mite a...

Embodiment 2

[0050] A washable and efficient anti-mite agent prepared from the following raw materials:

[0051] Acaricide ingredient: 2.7%, acaricide ingredient: 1.7%, dispersant 0.2%, emulsifier 1%, wall material 2%, buffer agent 5%, initiator 0.1%, coagulant 1%, the rest is absolute ethanol, Deionized water.

[0052] The preparation method comprises the following steps:

[0053] First add the acaricidal component, repellent component, dispersant, and deionized water into the beaker, heat it in a water bath for 30 minutes to 75°C, then keep it at a constant temperature of 50°C and stir for 60 minutes at a stirring speed of 600r / min, then add in sequence Continue to stir the wall material, coagulant, initiator and absolute ethanol, raise the temperature to 90°C and react for 1 hour, then add an emulsifier and continue stirring for 0.5 hour to make the wall material and core material emulsify evenly, and finally add a buffer to adjust the pH of the solution to 6. A high-efficiency anti-m...

Embodiment 3

[0056] A washable and efficient anti-mite agent prepared from the following raw materials:

[0057] Acaricidal ingredient: 1.8%, repellent ingredient: 5.8%, dispersant 0.5%, emulsifier 0.8%, wall material 1%, buffer 6%, initiator 0.3%, coagulant 2%, the rest is absolute ethanol, Deionized water.

[0058] The preparation method comprises the following steps:

[0059] First add the acaricidal component, repellent component, dispersant, and deionized water into the beaker, heat it in a water bath for 40 minutes to 90°C, then keep it at a constant temperature of 60°C and stir for 60 minutes at a stirring speed of 100r / min, then add in sequence Continue to stir the wall material, coagulant, initiator and absolute ethanol, raise the temperature to 70°C for 2 hours, then add emulsifier and continue stirring for 0.8 hours to make the wall material and core material emulsify evenly, and finally add buffer to adjust the pH of the solution to 8. A high-efficiency anti-mite agent that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com