Automatic precise milling machine machining and feeding and discharging device

A milling machine processing and precise technology, applied in positioning devices, milling machine equipment, metal processing and other directions, can solve the problems of position deviation, unstable grasping by the manipulator, inconvenient wheel processing and production, etc., and achieve the effect of reducing position deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

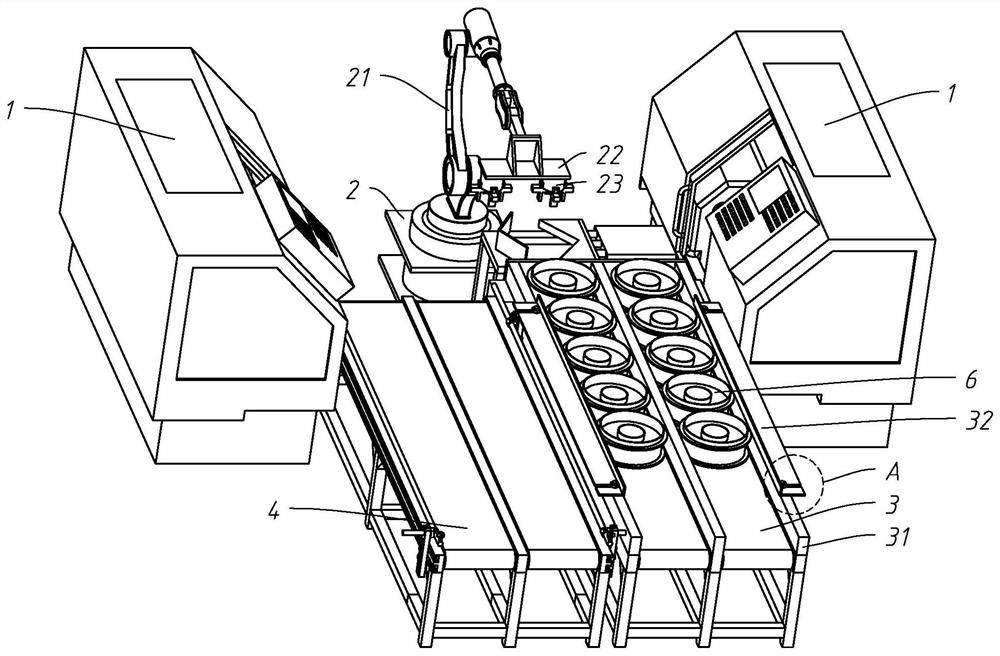

[0038] refer to figure 1 , an automatic precision milling machine processing and loading and unloading device, including a feeding conveyor belt 3 placed on the ground of the working environment and used to transport the hub 6. In this embodiment, the number of feeding conveyor belts 3 is two.

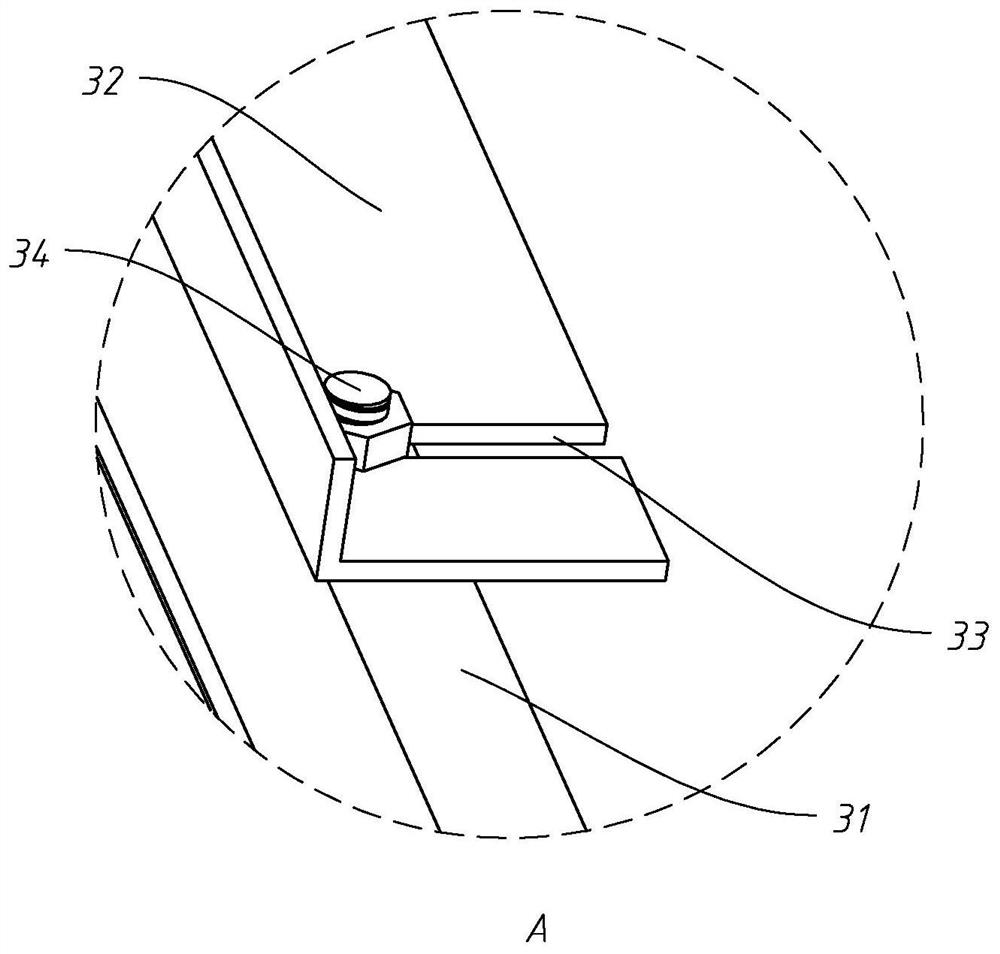

[0039] refer to figure 1 and figure 2 On both sides of the two feeding conveyor belts 3 and on the side near the output end of the feeding conveyor belt 3, baffles 31 are fixed, and an adjusting plate 32 is detachably connected to the top of the two side baffles 31, and the top of the adjusting plate 32 runs through. There is a strip hole 33 , the extension direction of the strip hole 33 is perpendicular to the conveying direction of the feeding conveyor belt 3 , and one end of the strip hole 33 communicates with the side wall of the regulating plate 32 . An adjusting bolt 34 is threaded on the strip hole 33, and the screw-in end of the adjusting bolt 34 is threaded with the baffle ...

Embodiment 2

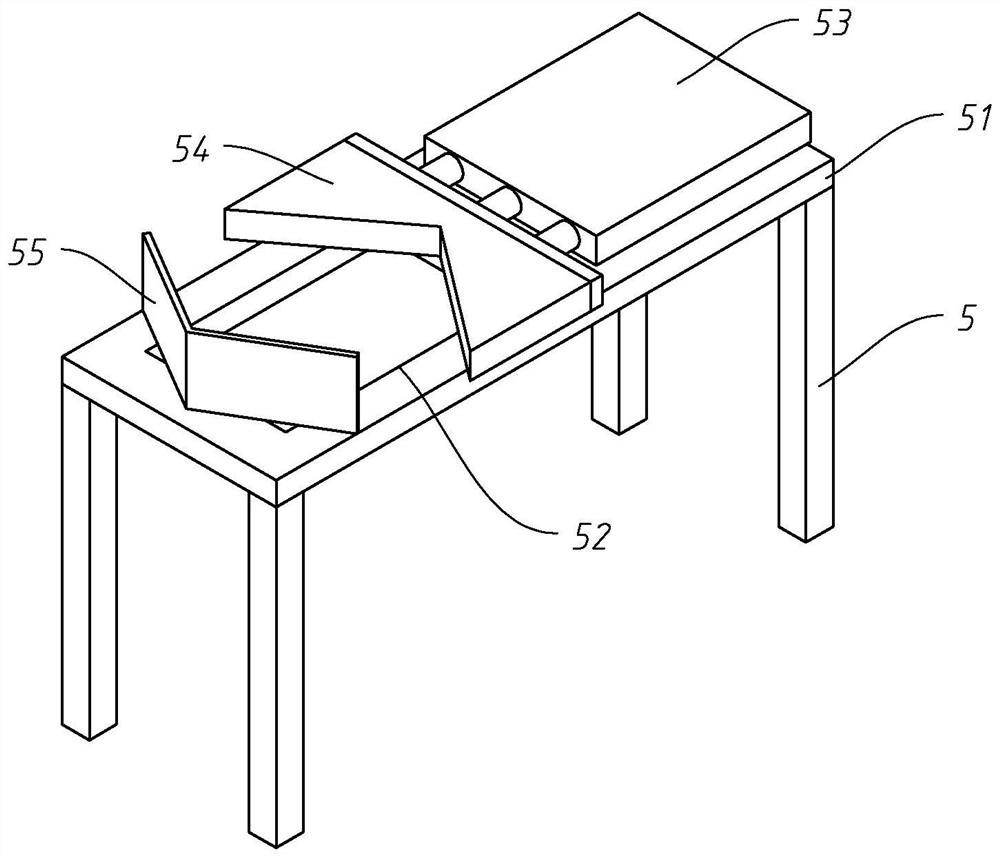

[0060] refer to Figure 4 , Different from Embodiment 1, in this embodiment, the first positioning block 54 and the second positioning block 55 are provided with arc-shaped slopes on opposite surfaces, and the openings of the two arc-shaped slopes are opposite to each other.

[0061] The implementation principle of an automatic precision milling machine processing and loading and unloading device in the embodiment of the present invention is as follows:

[0062] When the wheel hub 6 to be processed is transferred from the feeding conveyor belt 3 to the top plate 51 between the first positioning block 54 and the second positioning block 55, the hydraulic cylinder 53 is activated to make the piston rod push the first positioning block 54, so that the wheel hub 6 is in the The first positioning block 54 moves toward the second positioning block 55 under the clamping of the arc-shaped slope at the end, until the hub 6 is sandwiched between the arc-shaped slopes of the second posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com