A kind of preparation method of three-dimensional graphene composite material

A composite material, graphene technology, applied in the direction of additive processing, etc., to achieve the effects of excellent mechanical properties, improved accuracy, and rich raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

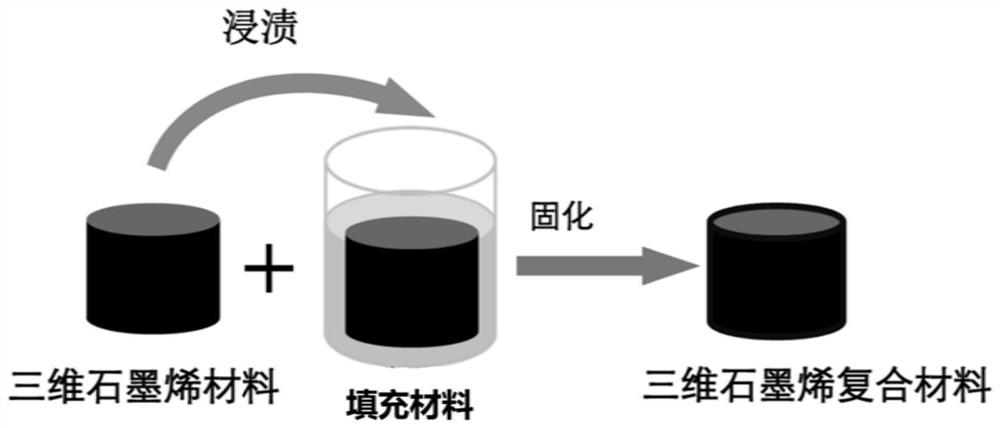

[0053] A preparation method of a three-dimensional graphene resin-based composite material, comprising the following steps:

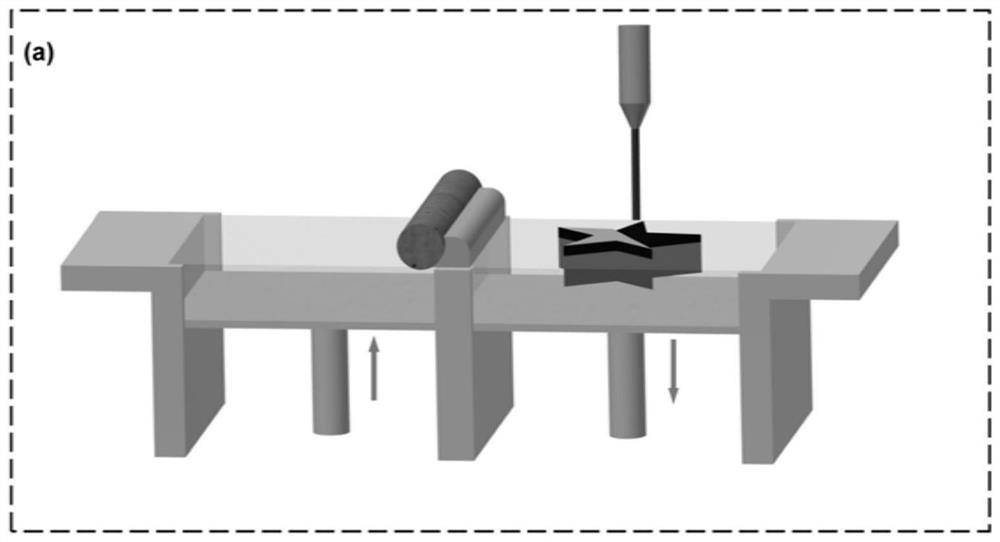

[0054] S1 substrate processing, fixing the polyimide (PI) paper on the bottom plate, and laser-induced the PI paper to produce a laser-induced graphene (LIG) substrate;

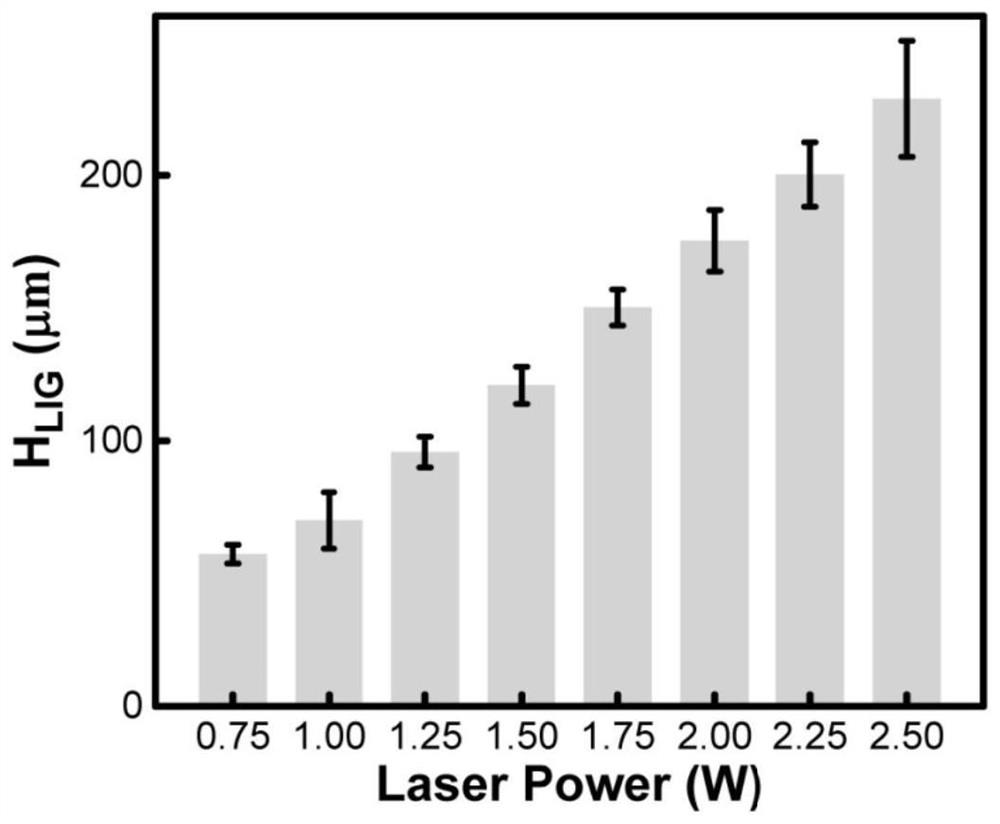

[0055] S2 powder spreading, spreading the polymer powder on the surface of the substrate LIG, the thickness of the powder layer is 60%-80% of the graphene growth height;

[0056] S3 laser induction, using CO 2 The laser performs laser selective carbonization on the laid polymer powder to form a pre-designed single-layer graphene film;

[0057] S4 continues to spread the powder, spread a layer of polymer powder on the surface of the formed graphene, and the thickness of the powder layer is 60%-80% of the growth height of the graphene;

[0058] S5 laser induction, using CO 2 The laser performs laser selective carbonization on the laid polymer powder to form a pre-designed single-layer...

Embodiment 1

[0068] A method for preparing a three-dimensional graphene resin-based material by 3D printing, comprising the following steps:

[0069] S1 substrate processing, fixing the polyimide (PI) paper on the aluminum plate, and laser-induced the PI paper to produce a laser-induced graphene (LIG) substrate;

[0070] S2 in the air atmosphere, spread the polyimide powder evenly on the LIG surface of S1, and use the laser to select the polyimide powder with a power of 1W, a scanning speed of 50.8mm / s and a printing resolution of 500 Sexual graphene;

[0071] S3 continues to spread the powder, on the surface of the formed graphene, carry out the second powder spreading, and the thickness of the powder spreading is 50 μm;

[0072] S4 laser induction, the laser is used to selectively graphenize the polyimide powder with a power of 1W, a scanning speed of 50.8mm / s and a printing resolution of 500 to form a pre-designed single-layer graphene film;

[0073] S5 prints layer by layer, repeatin...

Embodiment 2

[0079] A method for preparing a three-dimensional graphene resin-based composite material by 3D printing, comprising the following steps:

[0080] S1 substrate processing, fixing the polyimide (PI) paper on the aluminum plate, and laser-induced the PI paper to produce a laser-induced graphene (LIG) substrate;

[0081] In S2, the polyimide powder was evenly spread on the LIG surface of S1 in the air atmosphere, and the polyimide powder was processed by the laser with a power of 1.5W, a scanning speed of 50.8mm / s and a printing resolution of 500. Selective grapheneization;

[0082] S3 continues to spread the powder, on the surface of the formed graphene, carry out the second powder spreading, and the thickness of the powder spreading is 100 μm;

[0083] S4 laser induction, the laser is used to selectively graphenize the polyimide powder with a power of 1.5W, a scanning speed of 50.8mm / s and a printing resolution of 500 to form a pre-designed single-layer graphene film;

[0084...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com