Automatic aluminum alloy batching method and device

An automatic batching and aluminum alloy technology, which is applied in the direction of computer material science, instruments, manufacturing computing systems, etc., can solve the problems of manual batching calculation deviation, multi-condition restrictions, and the complexity of batching rules, so as to improve production efficiency and level, improve Accuracy and efficiency, the effect of saving manpower and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

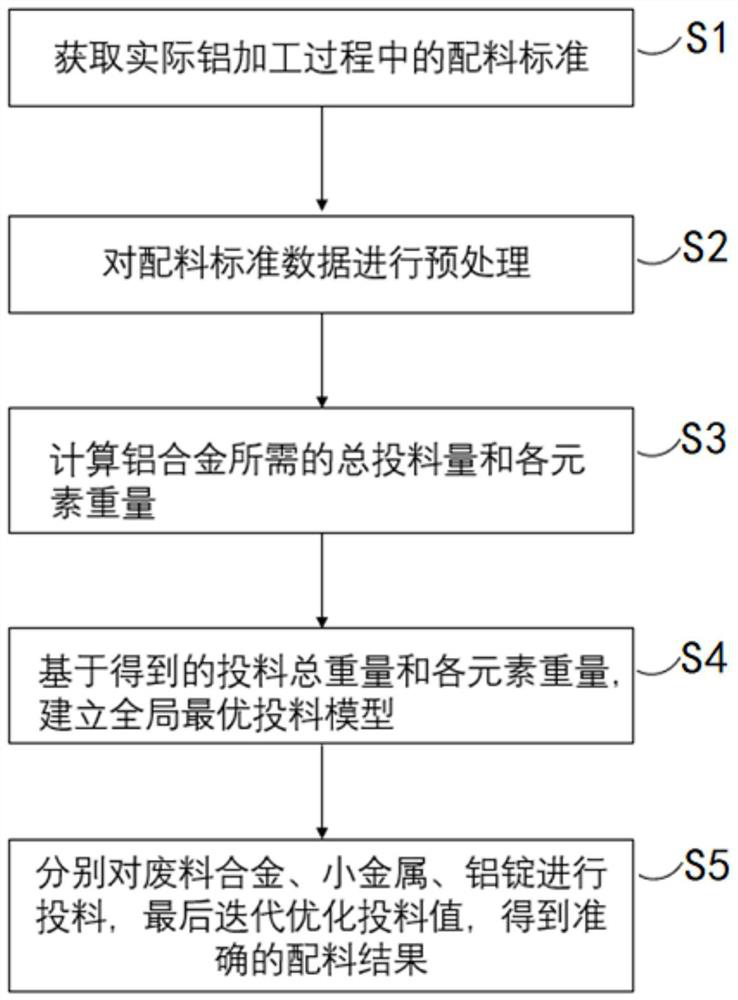

[0054] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

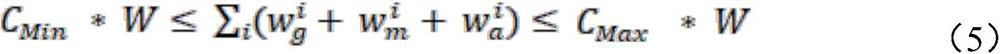

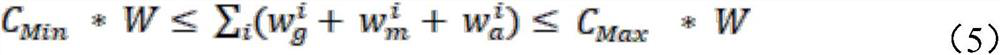

[0055] like figure 1 and figure 2 As shown, the aluminum alloy automatic batching method provided by the present invention comprises the following steps:

[0056] S1, obtain the ingredients standard in the actual aluminum processing process;

[0057] Specifically, it includes: obtaining the chemical composition standards before the production of aluminum alloys, process control standards, priority of use of waste materials, etc. Among them, the chemical composition standards mainly stipulate the element composition standards of the aluminum alloy, and the process control standards stipulate the weight ratio and grade of waste materials. Requirements, grade requirements for aluminum ingots, etc., priority of use of scrap alloys specifies the priority o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com