Spiral cross-shaped metal fuel element reactor core

A metal fuel and fuel element technology, applied in the direction of reactor fuel element, fuel element assembly, reactor fuel material, etc., can solve the problems of high peak fuel temperature, low thermal conductivity, large core volume, etc., and improve the outlet temperature. , low thermal conductivity, the effect of reducing core volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

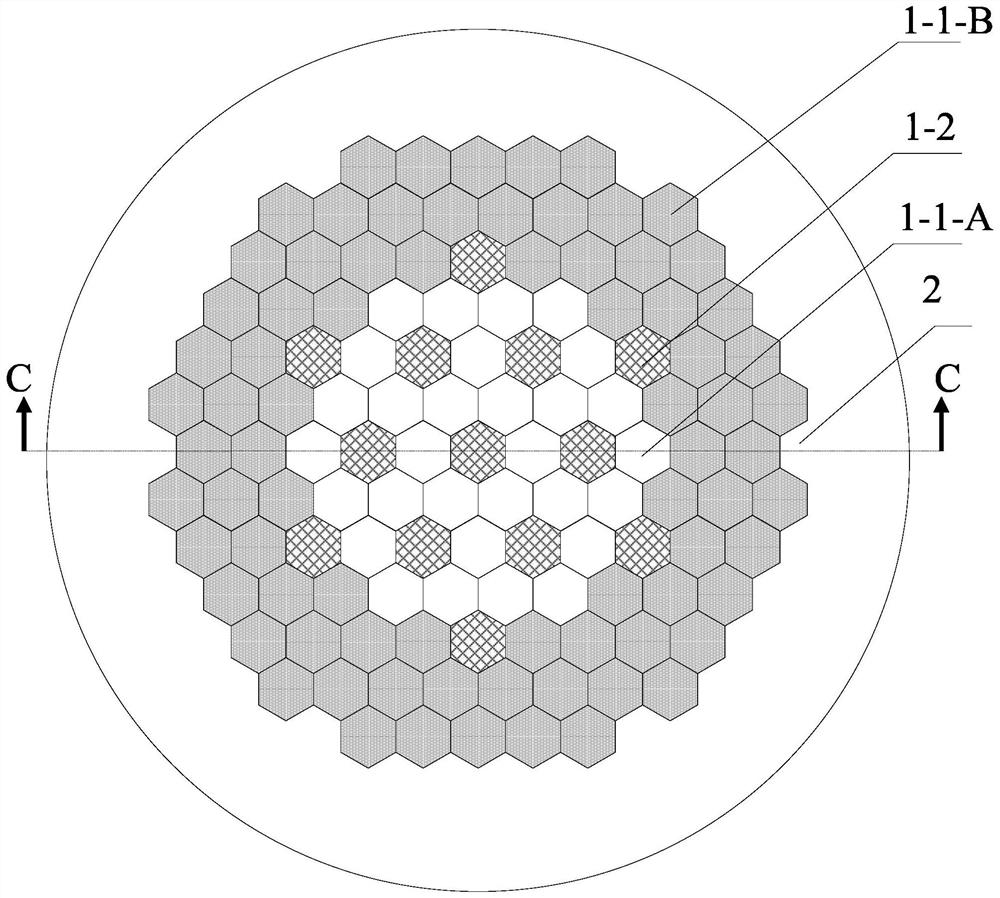

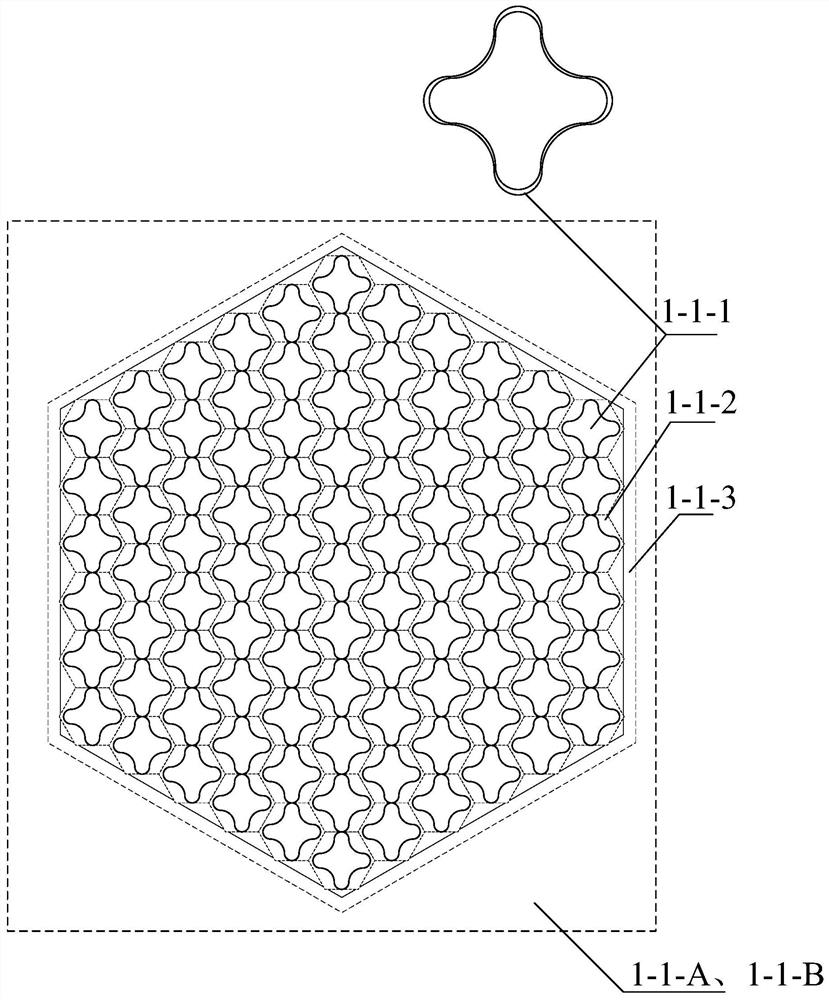

[0021] The invention provides a spiral cross-shaped metal fuel element core. Now, with reference to the accompanying drawings, the invention will be further described in detail by taking a small-scale fluoride-salt cooled high-temperature reactor core with a core thermal power of 125MW and a coolant of FLiBe as an example. Such as figure 1 and figure 2 Shown is an embodiment of the spiral cross fuel element small fluorine salt cooled high temperature stack of the present invention.

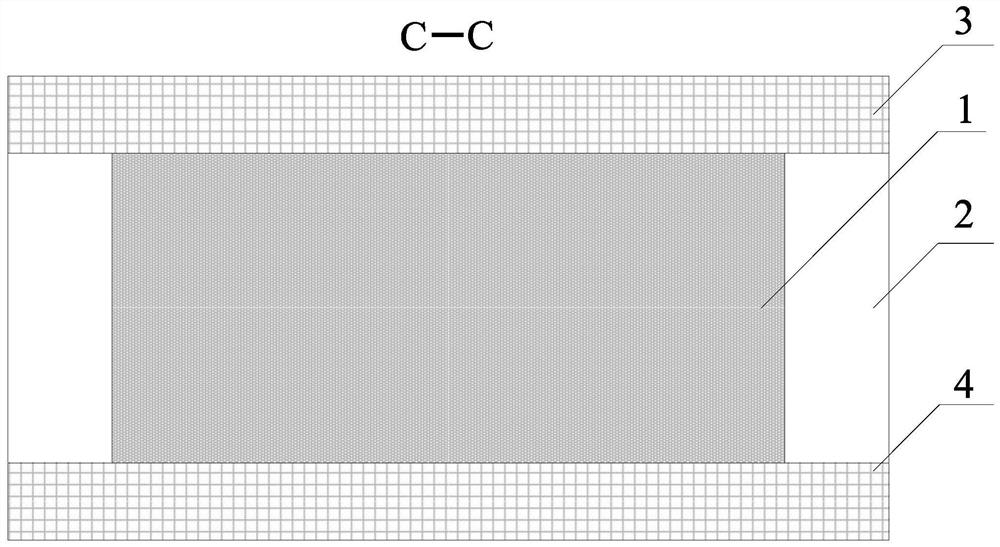

[0022] Such as figure 2 As shown, the spiral cross-shaped metal fuel element core includes a core active area 1, a radial reflector layer 2, an axially upward reflective layer 3 and an axially downward reflective layer 4; the spiral cross-shaped metal fuel element core, The core active area 1 is embedded in the radial reflective layer 2, the two are of the same height and the upper and lower end faces coincide with the central axis respectively; the axially upper reflective layer 3 and the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com