Capsule internal powder conveying and screening device and using method thereof

A screening device and powder technology, applied in heating devices, chemical instruments and methods, and sieves, can solve the problems of powder agglomeration, inconvenient filling, and increased powder volume, and achieve the effect of avoiding moisture agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

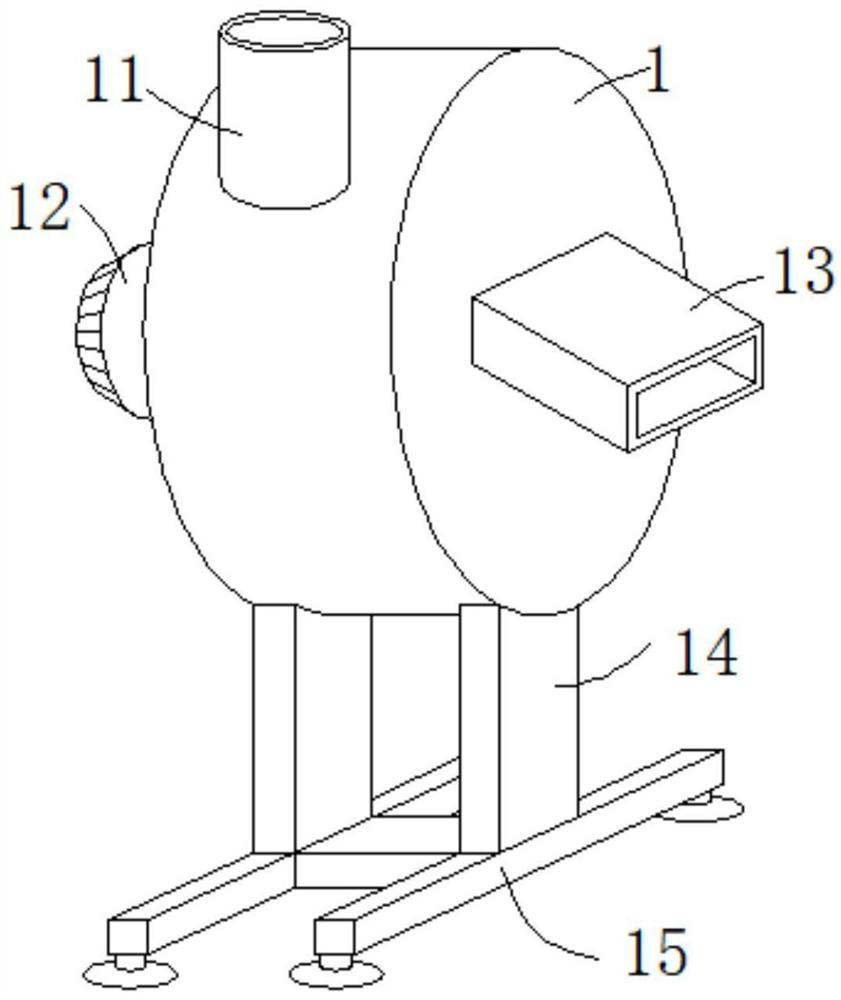

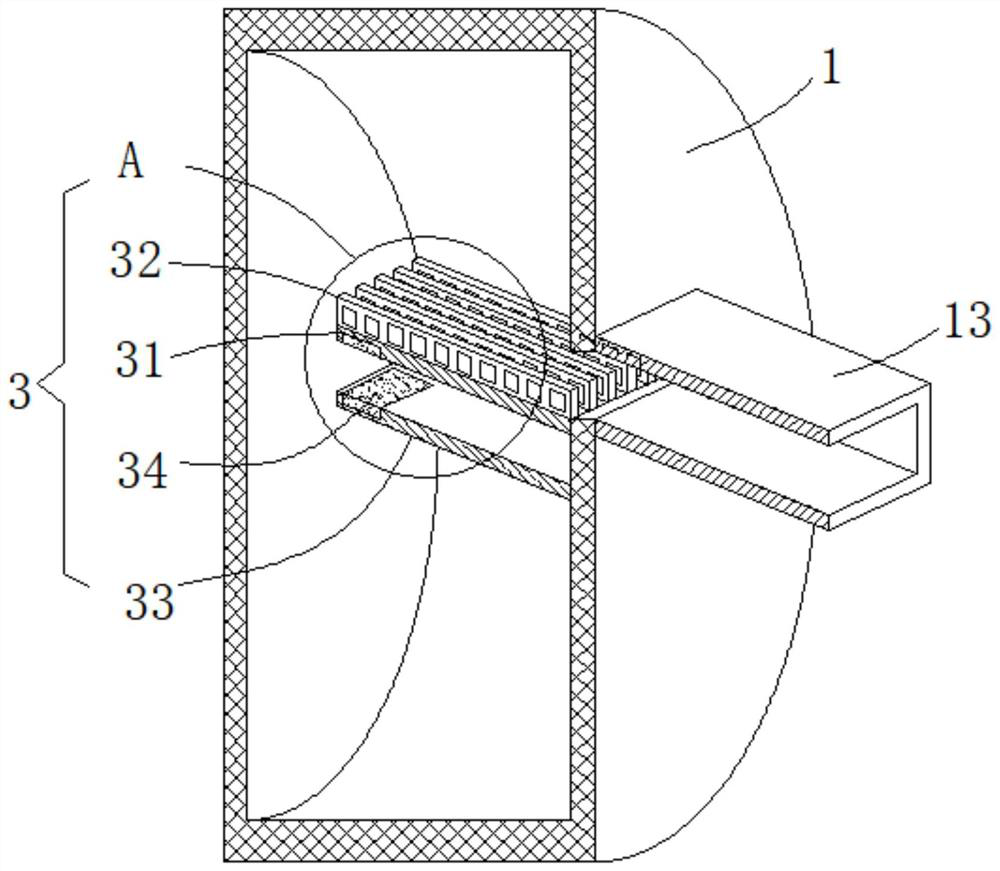

[0028] see Figure 1-4 , the present embodiment provides a powder transmission and screening device inside a capsule and its use method, including a screening cylinder 1 and a screening mechanism 3, the top of the outer wall of the screening cylinder 1 is provided with a feed port 16, and the top of the feed port 16 There is a feed pipe 11 at the opening, through which the capsule powder is fed into the feed port 16 and falls into the inside of the screening cylinder 1, waiting to be screened and the large agglomerated capsule powder is broken.

[0029] The right side wall of the screening cylinder 1 is provided with a discharge port and the opening of the discharge port is provided with a feed pipe 13 obliquely downward, through which the sieved capsule powder is conveniently exported to the feed pipe 13 .

[0030] The capsule powder will inevitably be deliquified and agglomerated during the transmission process, which will affect the packaging operation of the capsule powder...

Embodiment 2

[0036] see Figure 1-4 , further improvements have been made on the basis of Example 1:

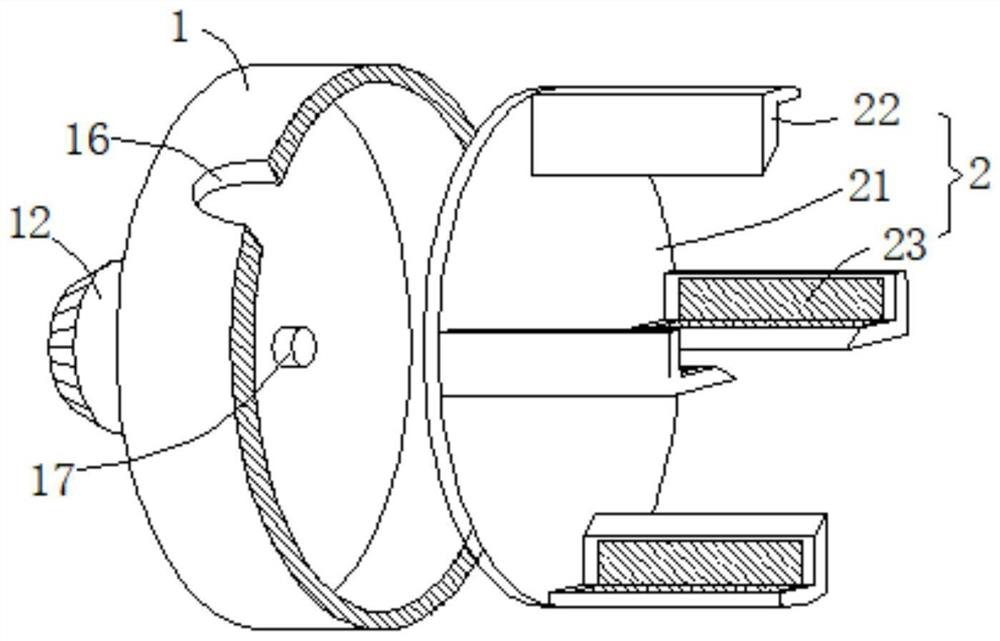

[0037] In order to feed the capsule powder into the screening cylinder 1, a driving motor 12 is fixed on the side wall of the screening cylinder 1 away from the discharge port, and the power shaft 17 of the driving motor 12 rotates through the screening cylinder 1 The side wall extends to the inside of the screening cylinder 1, and the drive motor 12 is used to provide power to drive the power shaft 17 to rotate. The inside of the screening cylinder 1 is provided with a material pushing mechanism 2, which follows the power shaft 17 of the driving motor 12 through the material pushing mechanism 2 Rotate so that the feeding mechanism 2 performs a feeding operation on the capsule powder delivered into the screening cylinder 1.

[0038] The material shifting mechanism 2 includes a turntable 21, the side wall of the turntable 21 is connected with the power shaft 17 of the drive motor 12, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com