Three-dimensional track conveying type tool magazine

A conveying and three-dimensional technology, applied in the field of tool magazines, can solve the problems of inability to make the chain structure, unstable chain transmission, and high power of the transmission motor, and achieve the effects of low motion noise, simple structure, and small transmission load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

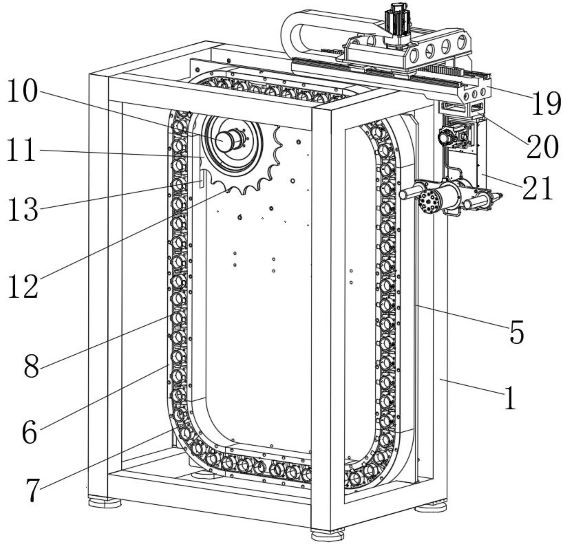

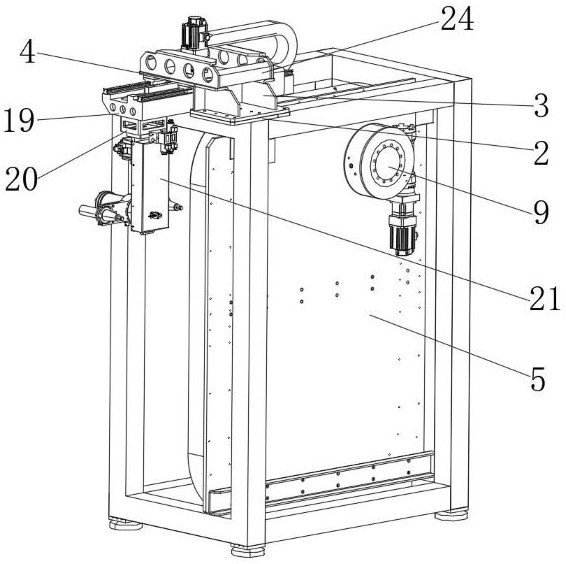

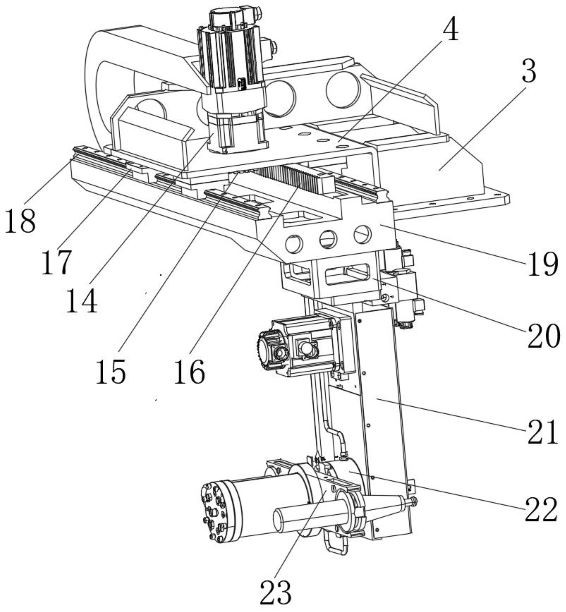

[0034] Such as Figure 1-6As shown, a three-dimensional track conveying type tool magazine includes a mounting bracket 1, a mounting plate 2 is installed on the right side of the upper rear part of the mounting bracket 1, a mounting seat 3 is installed on the upper end of the mounting plate 2, and the upper end front of the mounting seat 3 A support 4 is installed, the support 4 is an L-shaped structure, the upper front of the support 4 is equipped with a servo motor 14, the output end of the servo motor 14 runs through the lower front of the support 4 and a drive gear 15 is installed, and the drive gear One side of 15 is connected with transmission rack 16, and the front part of the lower end of support 4 is equipped with slide block 17, and slide block 17 is provided with two groups and is distributed in front and back, and slide block 17 is set to every group two and is distributed in left and right , the lower ends of the two groups of sliders 17 are slidingly connected wi...

Embodiment 2

[0039] Figure 7 The three-dimensional track conveying tool magazine is different from Embodiment 1 in that the shape of the conveying track 6 is crescent-shaped, and the crescent-shaped conveying track 6 can accommodate more tool pockets 8 without changing the existing volume of the tool magazine. Under the premise, more processing knives can be installed and transported, and the practicability is higher. All the other structures are the same as in Example 1.

Embodiment 3

[0041] Figure 8 The three-dimensional rail conveying type tool magazine is different from Embodiment 1 in that the shape of the conveying rail 6 is crescent-shaped and there are two conveying rails 6. Correspondingly, the vertical plate 5, the reduction motor 9 and the driving wheel 11 are all provided There are two. At the same time, there is a linear drive mechanism between the mounting base 3 and the mounting plate 2 that drives the mounting base 3 to move perpendicular to the paper surface. The linear drive mechanism can be composed of a linear motor module or a motor. , gears, racks and linear guide rails, the linear drive mechanism drives the mounting seat 3 to move, so that the mounting seat 3 moves from one conveying track 6 to another conveying track 6, so that the tool changer arm 23 can be between the two conveying tracks 6 Move, so that the tool changing arm 23 can pick up and change the tool at the two conveying rails 6, and carry out 3D three-dimensional transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com