A kind of tungsten trioxide-titanium dioxide electrochromic film and preparation method thereof

An electrochromic and thin-film technology, applied in instruments, coatings, optics, etc., can solve the problem of failing to achieve selective regulation of visible light bands and near-infrared light bands, and not involving near-infrared light "dual-frequency" electrochromic effects , Only consider the light modulation effect and electrochemical performance, etc., to achieve the effect of easy online large-area coating, improve coloring efficiency, and controllable products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

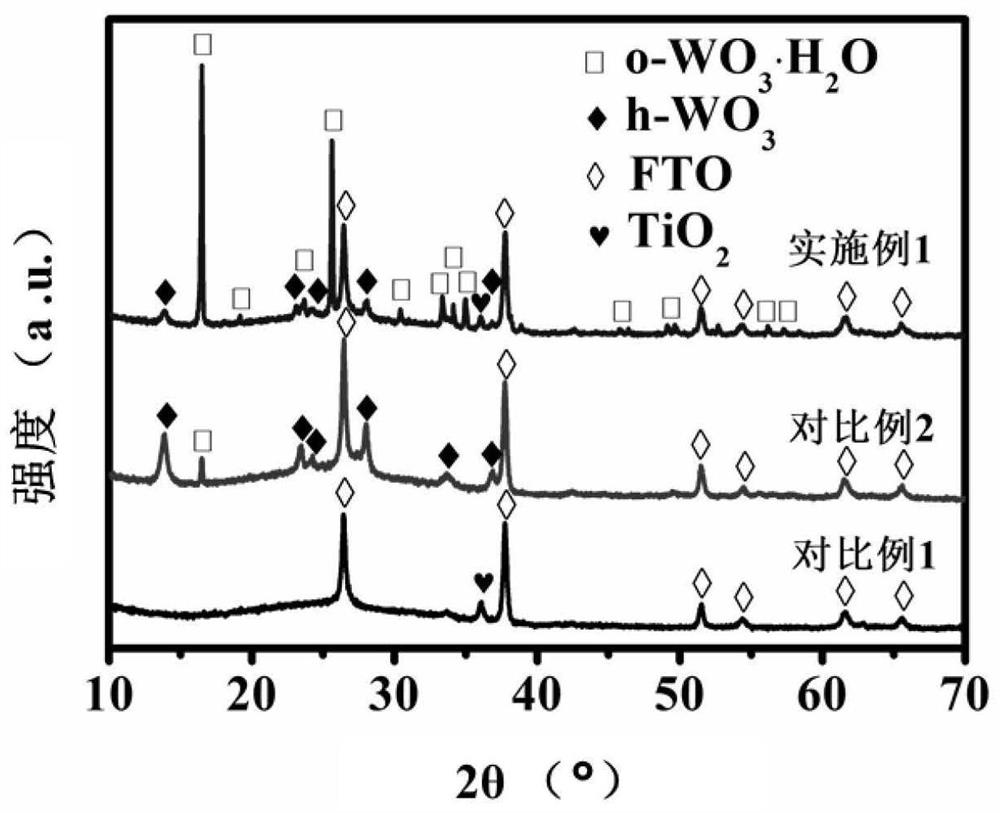

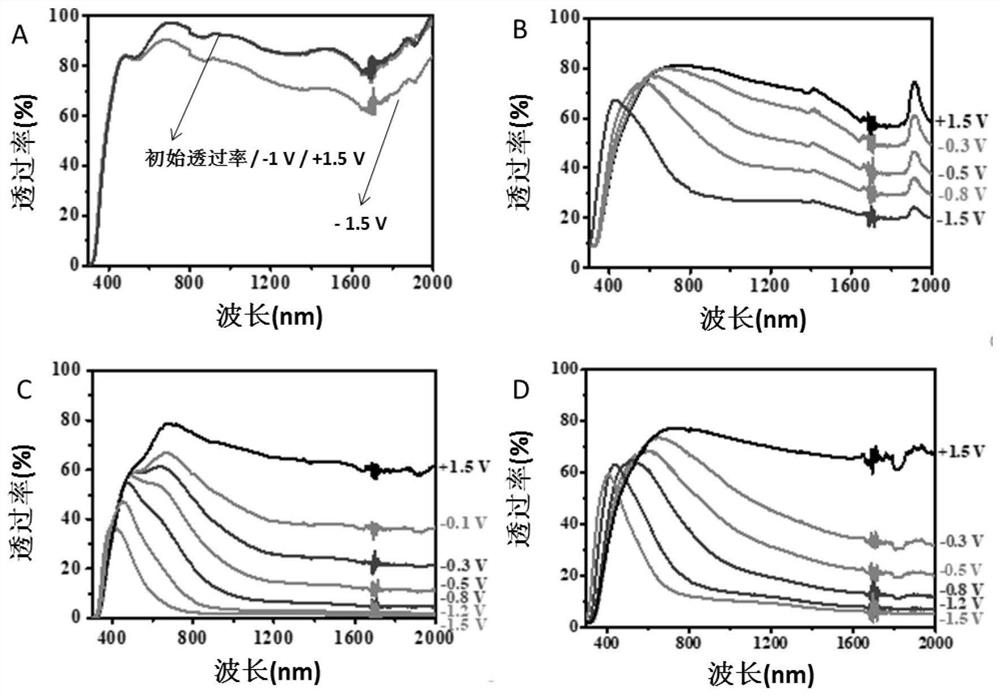

Embodiment 1

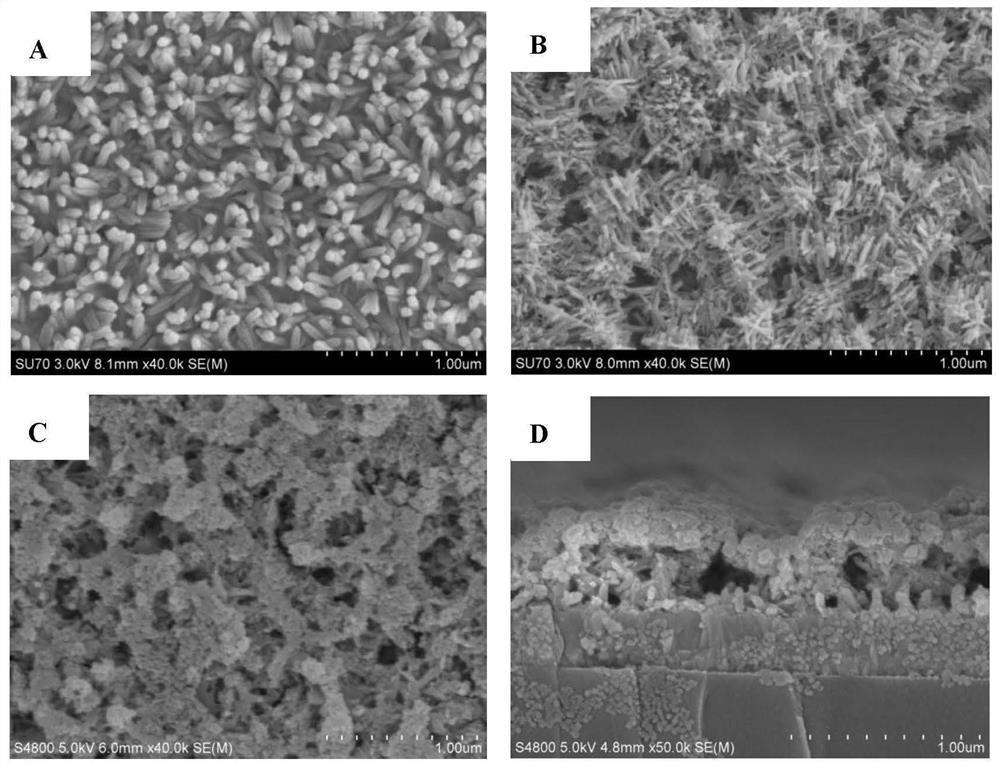

[0044] (1) Mix 30 mL of concentrated hydrochloric acid, 30 mL of deionized water and 1.2 mL of butyl titanate, and magnetically stir for 1 h to prepare a titanium dioxide precursor solution; FTO conductive glass (30 mm × 30 mm × 1 mm) was mixed with deionized water and alcohol After ultrasonic cleaning, it was put into a 50mL high-pressure reactor liner, and then 20mL of titanium dioxide precursor solution was added to it to generate a hydrothermal reaction. The hydrothermal reaction conditions were: 130°C, 2h; 2 Array of conductive glass;

[0045] (2) Dissolve 3.3g of sodium tungstate dihydrate in 120mL of deionized water, heat and stir at 70°C for 30min, place in cold water to cool, add 100mL of 0.25mol / L HCl solution until no more precipitation is formed; remove the supernatant , the precipitate was washed with deionized water until the pH of the washing solution was 2.4, the total volume was 120 mL, and then 3 mL of 30 wt.% H was added. 2 O 2 The solution was stirred at ...

Embodiment 2

[0048] (1) Mix 30 mL of concentrated hydrochloric acid, 30 mL of deionized water and 0.9 mL of butyl titanate, and magnetically stir for 1 h to make a titanium dioxide precursor solution; FTO conductive glass (30 mm × 30 mm × 1 mm) was mixed with deionized water and alcohol After ultrasonic cleaning, it was put into a 50mL high-pressure reactor liner, and then 20mL of titanium dioxide precursor solution was added to it to generate a hydrothermal reaction. The hydrothermal reaction conditions were: 130°C, 2h; 2 Array of conductive glass;

[0049] (2) Dissolve 3.3g of sodium tungstate dihydrate in 120mL of deionized water, heat and stir at 70°C for 30min, place in cold water to cool, add 100mL of 0.25mol / L HCl solution until no more precipitation is formed; remove the supernatant, The precipitate was washed with deionized water until the pH of the washings was 2.4 and the total volume was 120 mL, followed by the addition of 3 mL of 30 wt.% H 2 O 2 The solution was stirred at 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com