A kind of niobium pentoxide electrochromic film, hydrothermal synthesis method and use thereof

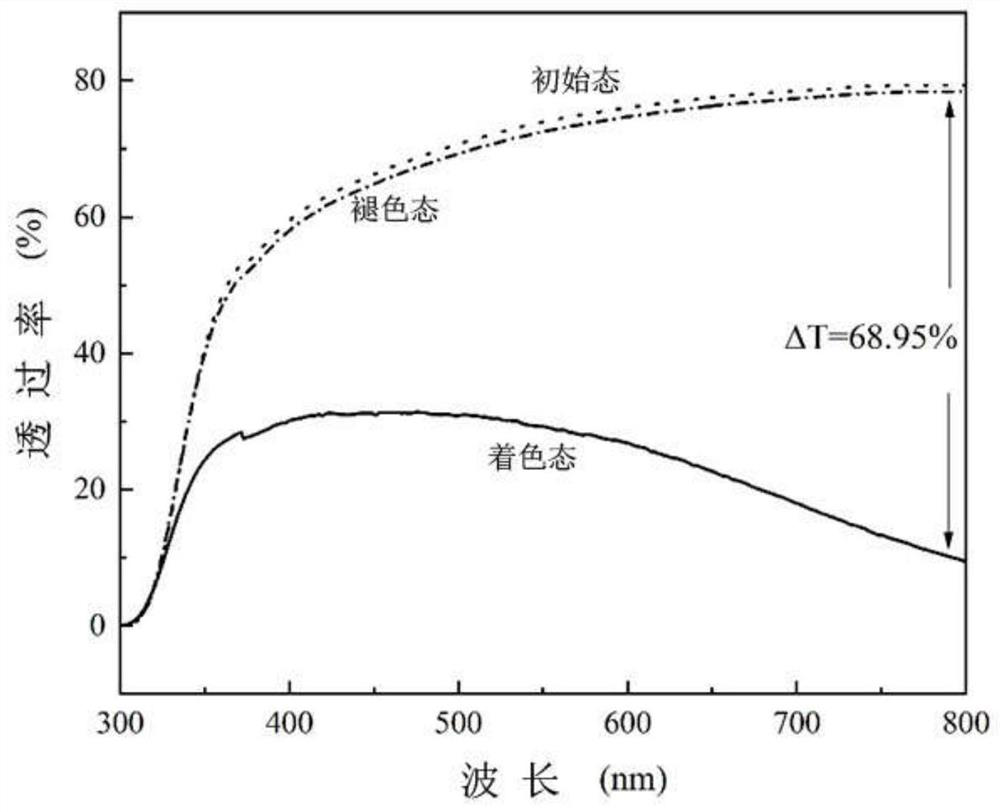

A niobium pentoxide and electrochromic technology, which is applied in coatings and other directions, can solve the problems of unsatisfactory light modulation amplitude and cycle stability, high preparation conditions, and short service life of color-changing devices. Chromogenic properties, low requirements for preparation conditions, high light modulation amplitude effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Cut the FTO conductive glass into 50mm × 25mm rectangular pieces, and then place them in acetone, ethanol and deionized water in sequence, and ultrasonically clean them for 5 to 10 minutes each. use.

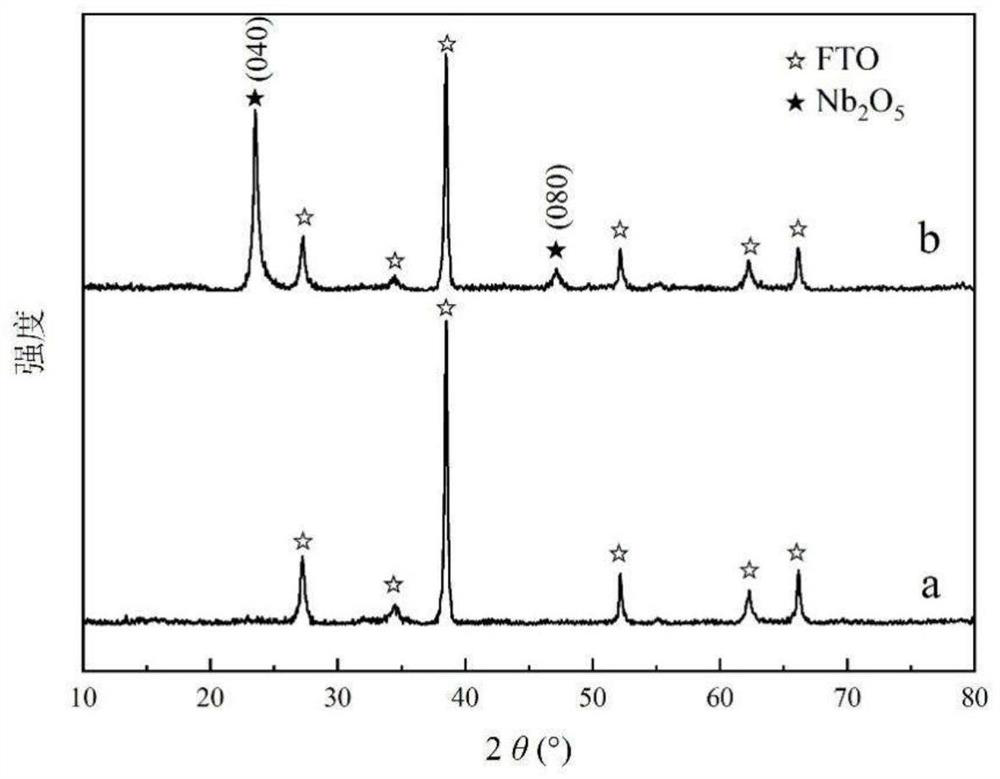

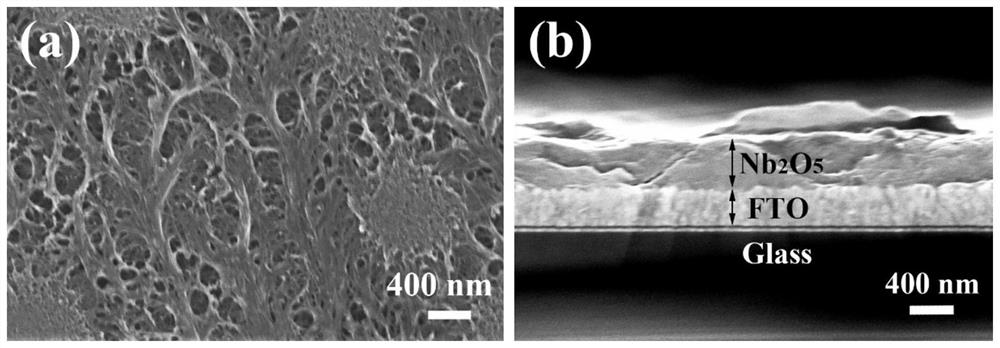

[0036]Measure 18 mL of absolute ethanol and 42 mL of deionized water, and mix them evenly to obtain solution A. Weigh 3.2 g of commercially available niobium oxalate powder, add solution A, place in a 100 mL volume beaker, and stir with a magnetic stirrer at medium speed until colorless and transparent to obtain a niobium pentoxide precursor solution. Then move the solution to the lining of a 100mL capacity polytetrafluoroethylene high-pressure hydrothermal kettle, place a piece of pretreated FTO conductive glass conductive side down, and insert it into the solution at an angle of 75° to the horizontal line, the FTO conductive glass is beyond the liquid surface 10mm. After sealing the steel shell of the high-pressure hydrothermal kettle, it was put into an oven for hydr...

Embodiment 2

[0041] The pretreatment method of the FTO conductive glass is the same as that of Example 1.

[0042] Measure 24 mL of absolute ethanol and 36 mL of deionized water, and mix them evenly to obtain solution B. Weigh 3.2 g of niobium oxalate powder, add solution B, place in a 100 mL volume beaker, and stir with a magnetic stirrer at medium speed until colorless and transparent to obtain a niobium pentoxide precursor solution. Then move the solution to the lining of a 100mL capacity polytetrafluoroethylene high-pressure hydrothermal kettle, place a piece of pretreated FTO conductive glass conductive side down, and insert it into the solution at an angle of 75° with the horizontal line, the FTO conductive glass exceeds the liquid surface 10mm. After sealing the steel shell of the high-pressure hydrothermal kettle, it was put into an oven for hydrothermal reaction. The temperature of the oven was set to 160° C. and the reaction time was 3h. After the hydrothermal reaction was comp...

Embodiment 3

[0045] The specific embodiment and the test method are the same as in Example 1, except that the volume ratio of deionized water and ethanol is 4:1, that is, 12 mL of absolute ethanol and 48 mL of deionized water.

[0046] The electrochromic properties of the niobium pentoxide thin films prepared in Examples 1 to 3 are shown in Table 1:

[0047] Table 1 Data Summary of Examples 1 to 3

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| coloring efficiency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com