Long-shaft submerged pump with good stability

A long-axis submerged and stable technology, which is applied to components of pumping devices for elastic fluids, pumps for special fluids, pumps, etc., can solve submerged pump vibration, shorten the service life of shaft sleeves, and reduce the temperature of pump shafts. Lifting and other problems, to facilitate inspection and maintenance, avoid resonance problems, improve the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

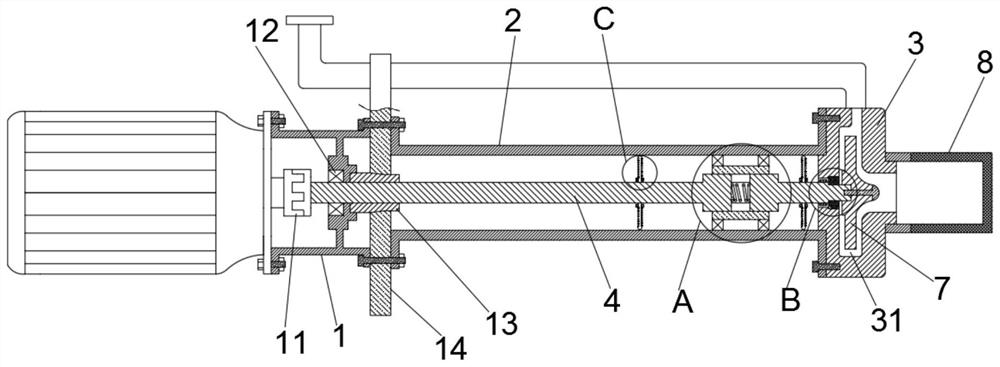

[0028] Such as Figure 1-3 As shown, the long-axis submerged pump of the present invention includes the main shaft 4 arranged in the shaft housing 2, the two ends of the shaft housing 2 are respectively connected with the mounting plate 14 and the pump housing 3, the pump housing 3 is provided with a chamber 31, the pump The bottom of the shell 3 is provided with a liquid inlet, and a net cover is installed on the liquid inlet. One side of the installation plate 14 is installed with a drive motor through the connecting frame 1, and the driving motor is connected with the main shaft 4 through the coupling 11. Support plate, fixed bearing 12 and limit sleeve 13 are respectively fixedly installed on both sides of the support plate, limit sleeve 13 is fixedly connected with mounting plate 14, main shaft 4 passes through fixed bearing 12 and limit sleeve 13.

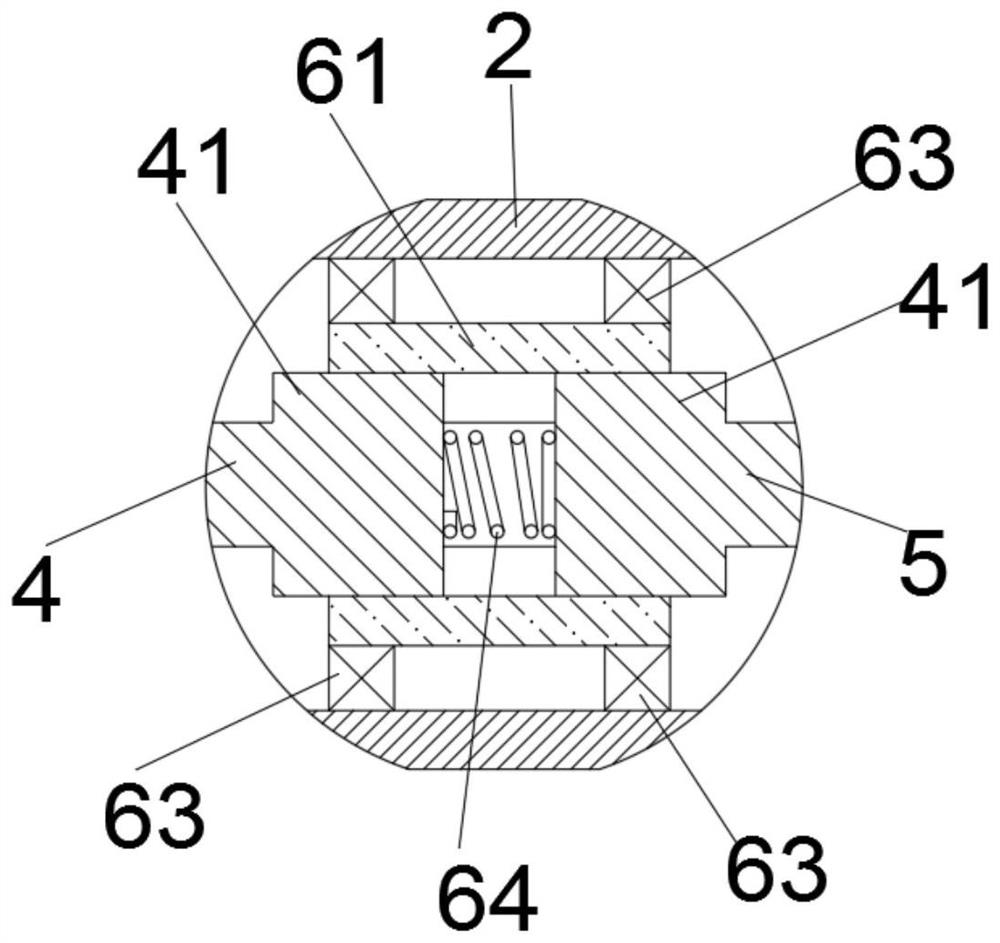

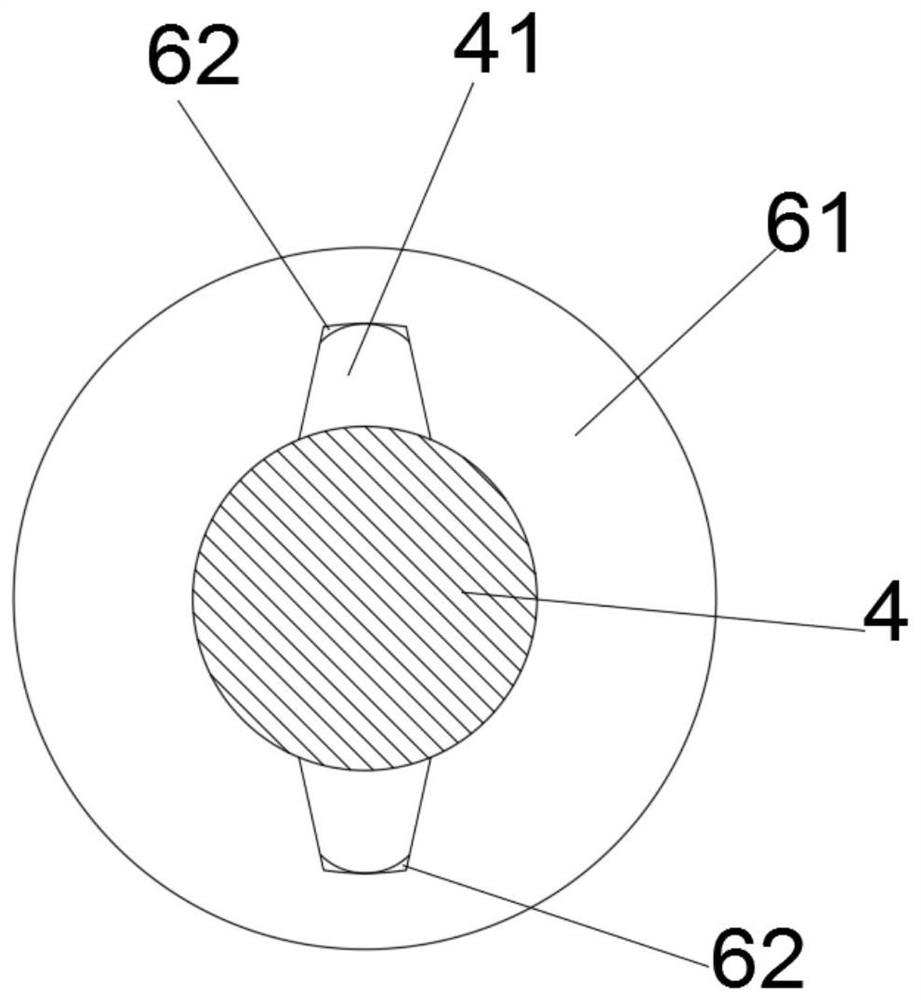

[0029] The other end of the main shaft 4 is connected with the rotating shaft 5 through the connecting device, the top of t...

Embodiment 2

[0032] As a further technical solution of the present invention, such as Figure 5 As shown, two adjustment devices are evenly installed on the surface of the main shaft 4, and two adjustment devices are evenly installed on the surface of the rotating shaft 5 at the same time. The adjustment device includes a mounting rod 42, a second spring 44, and a counterweight ring 45. The mounting rod 42 is fixedly mounted on the corresponding rotating shaft 5 or main shaft 4, and the end of the mounting rod 42 is provided with a limit ball 43, and the counterweight ring 45 The second spring 44 is installed on the installation rod 42 between the limit ball 43 and the weight ring 45 . During the rotation of the rotating shaft 5 and the main shaft 4, under the action of centrifugal force, the counterweight ring 45 can compress the second spring 44, and adjust the position of the counterweight ring 45 on the mounting rod 42, thereby realizing the alignment between the rotating shaft 5 and t...

Embodiment 3

[0034] As a further technical solution of the present invention, such as Figure 4As shown, the sealing device includes a connecting bearing and a rubber sealing ring, the connecting bearing and the rubber sealing ring are closely connected with the pump casing 3, the connecting bearing is located on one side of the chamber 31, and the outer diameter of the connecting bearing is larger than the outer diameter of the rubber sealing ring, and the rubber sealing ring The sealing ring is in close contact with the connecting bearing, and the rubber sealing ring is in surface contact with the inner ring 33 and the outer ring 32 of the connecting bearing respectively. The inner wall of the rubber sealing ring 34 is provided with two ring grooves 35, and the ring groove 35 is provided with a silicone ring 36. The width of the silicone ring 36 is greater than the depth of the ring groove 35, and the silicone ring 36 contacts with the surface of the rotating shaft 5. Under the sealing e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com