Eddy current thermal imaging defect reconstruction method based on electrical impedance tomography

A technology of electrical impedance imaging and thermal imaging, which is applied in the field of defect detection, can solve the problem that it is difficult to obtain the true shape of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

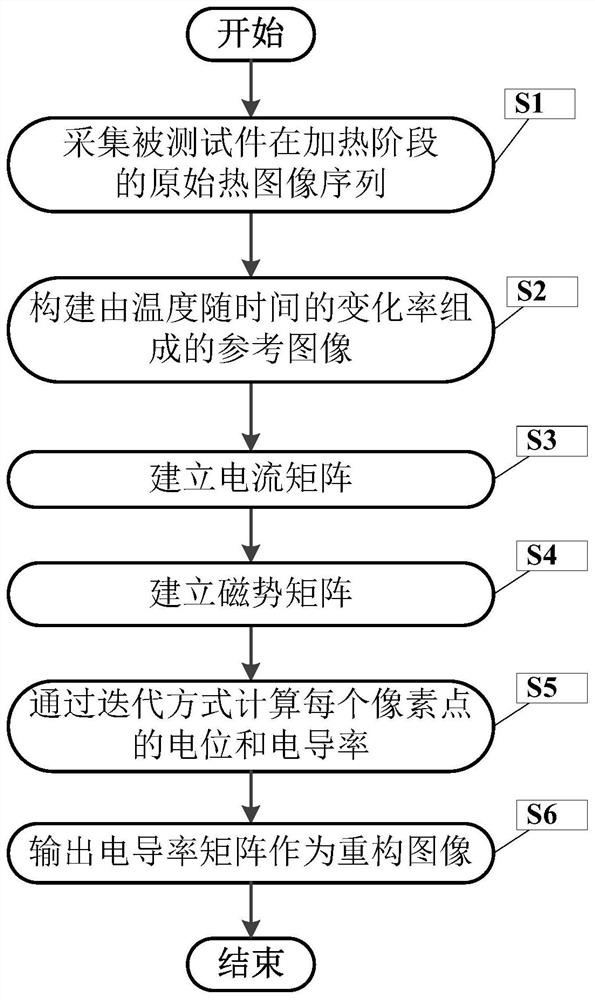

[0066] figure 1 It is a flowchart of a defect reconstruction method based on electrical impedance imaging in eddy current thermal imaging according to the present invention.

[0067] In this example, if figure 1 As shown, the present invention is based on electrical impedance imaging eddy current thermal imaging defect reconstruction method, comprising the following steps:

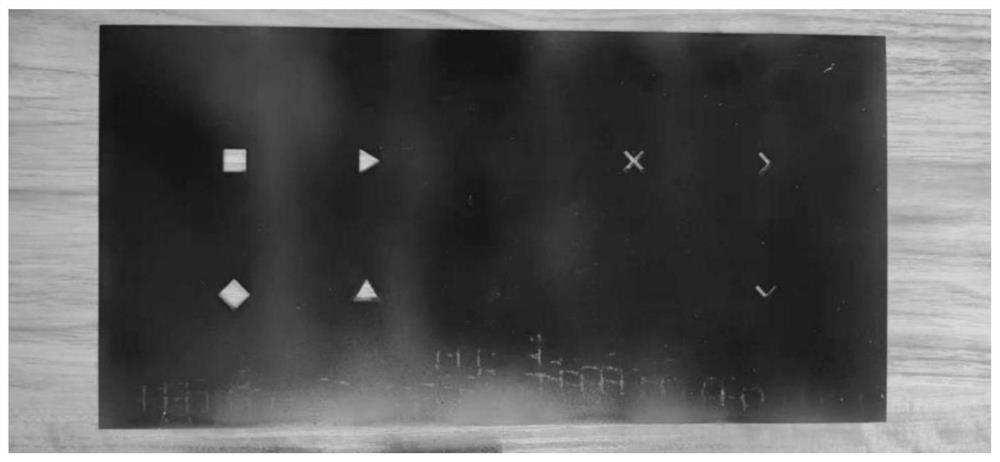

[0068] S1. Use a coil to excite the test piece. The coil is a high-conductivity hollow copper tube with an inner diameter of 6.35mm, and a current with a frequency of 275kHz and an amplitude of 150A is passed through. The tested piece is austenitic 304 stainless steel with a thickness of 0.28mm. Defects of different shapes are engraved, such as figure 2 shown. The coil is placed horizontally on the surface of the test piece, and the lifting distance from the test piece is 1cm. When the current is passed through the coil, heating starts, and the heating time is 200ms. Use an infrared thermal imager to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com