Tetragonal-phase high-entropy thermal barrier coating material and preparation method thereof

A technology of thermal barrier coating and tetragonal phase, which is applied in the field of tetragonal phase high-entropy thermal barrier coating material and its preparation, and can solve the problems of poor phase stability at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Multicomponent Zr designed according to high entropy 1-4x Y x m x Ta x Nb x o 2 Weigh a certain amount of each oxide powder (wherein x is taken as 0.2, and the component is Zr 0.2 Y 0.2 Yb 0.2 Ta 0.2 Nb 0.2 o 2 ), including ZrO 2 , Y 2 o 3 , Yb 2 o 3 、 Ta 2 o 5 , Nb 2 o 5 The oxide powders were placed in different alumina crucibles, put into a box-type muffle furnace and kept at 1000 °C for 2 h, and the heating rate and cooling rate were controlled at 5 °C / min to remove the adsorbed water and Impurities.

[0028] Pour the calcined oxide powders into a high-energy ball mill jar, add a certain amount of isopropanol (100ml) and zirconia balls (0.3mm, the ball-to-material ratio is 10:1), and perform high-energy ball milling. The rotating speed is 2500 / min, and the ball milling time is 12h.

[0029] The suspension after high-energy ball milling is separated from the ball material, washed 6 times with absolute ethanol, and the obtained mixed suspension is...

Embodiment 2

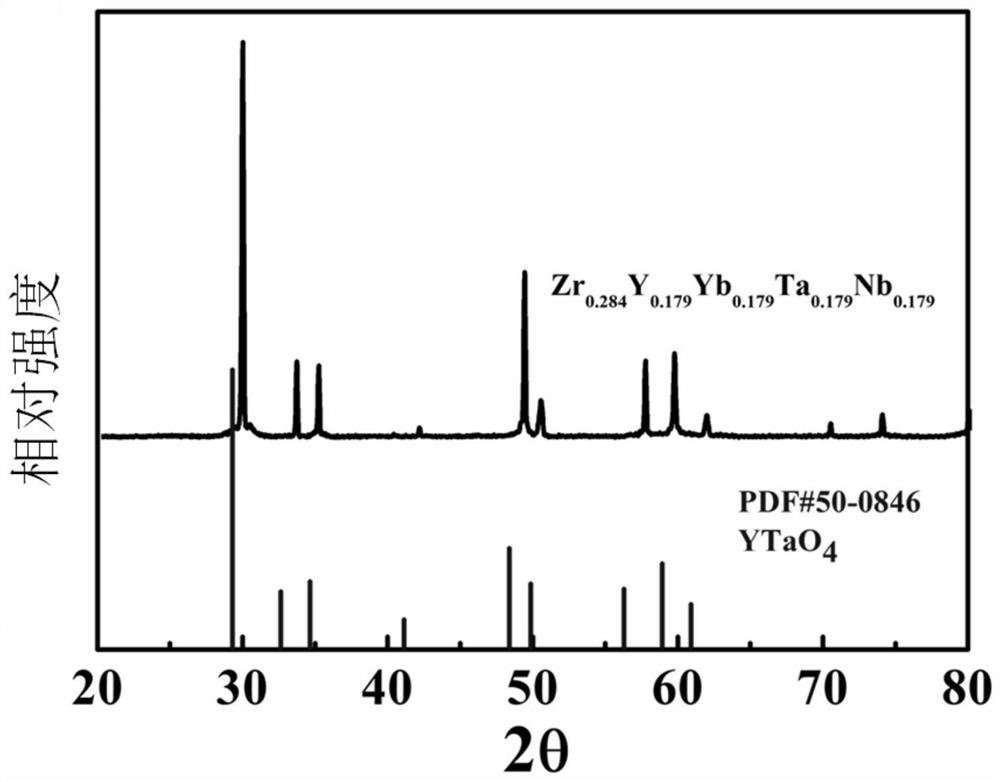

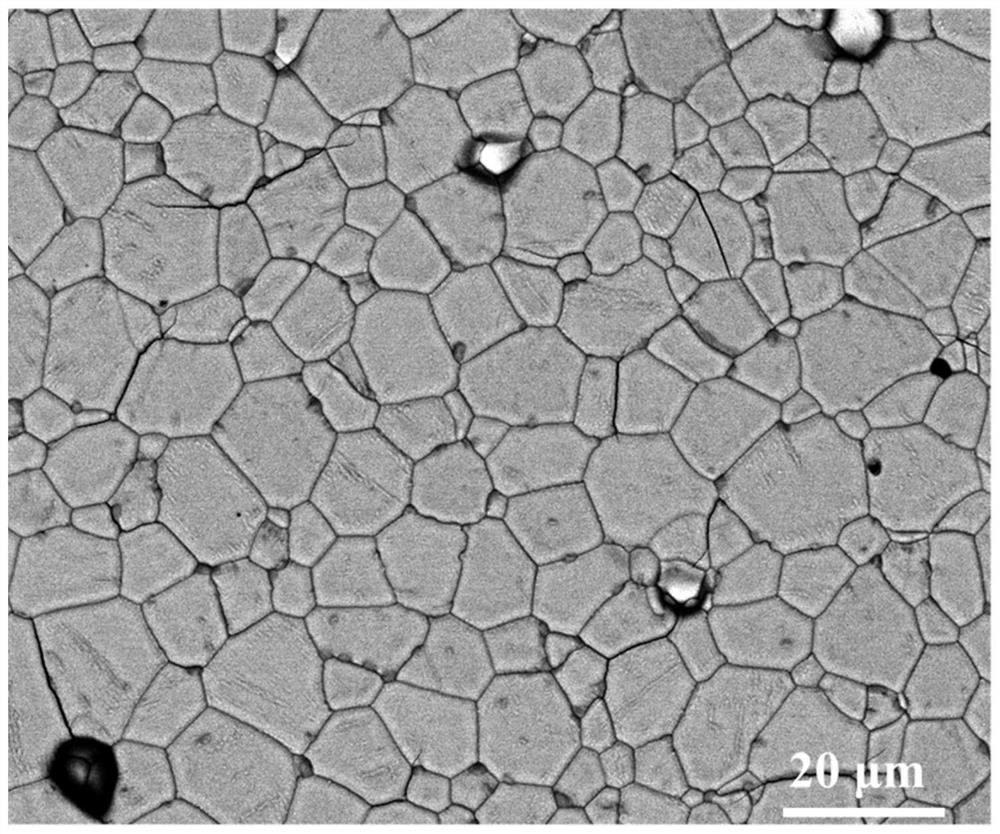

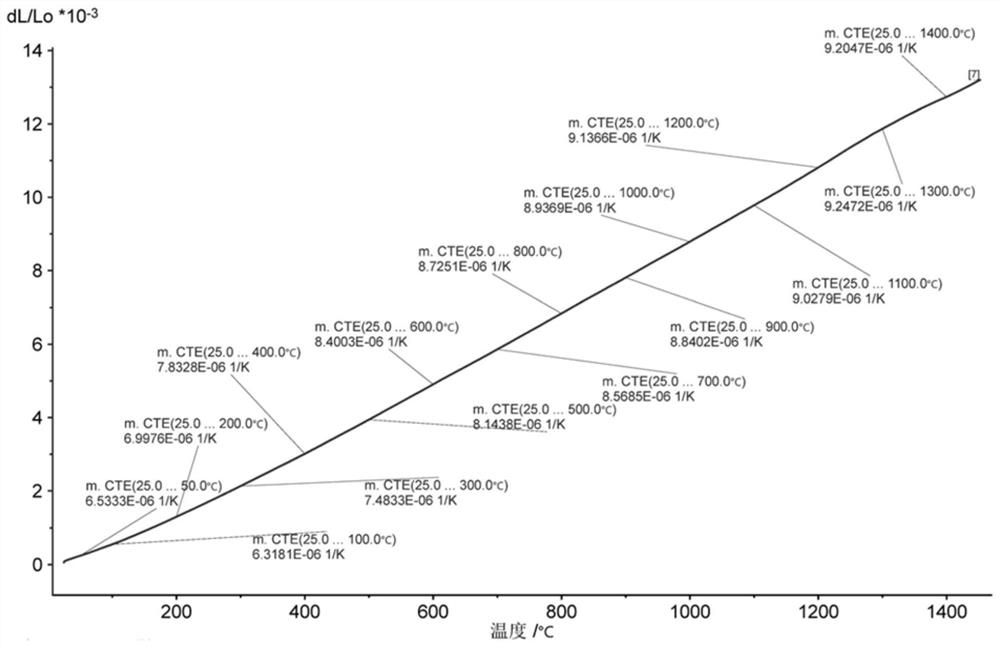

[0037] Multicomponent Zr designed according to high entropy 1-4x Y x m x Ta x Nb x o 2 Weigh a certain amount of each oxide powder (where x is 0.179, and the component is Zr 0.284 Y 0.179 Yb 0.179 Ta 0.179 Nb 0.179 o 2 ), including ZrO 2 , Y 2 o 3 , Yb 2 o 3 、 Ta 2 o 5 , Nb 2 o 5 The oxide powders were placed in different alumina crucibles, put into a box-type muffle furnace and kept at 1000 °C for 1 h, and the heating rate and cooling rate were controlled at 10 °C / min to remove the adsorbed water and Impurities.

[0038] Pour the calcined oxide powders into a high-energy ball mill tank, add a certain amount of isopropanol (120ml) and zirconia balls (0.4mm, the ball-to-material ratio is 10:1), and perform high-energy ball milling. The rotating speed is 2100r / min, and the ball milling time is 12h.

[0039] The suspension after high-energy ball milling is separated from the ball material, washed 6 times with isopropanol, and the obtained mixed suspension is ...

Embodiment 3

[0050] Multicomponent Zr designed according to high entropy 1-4x Y x m x Ta x Nb x o 2 Weigh a certain amount of each oxide powder (where x is 0.119, and the component is Zr 0.524 Y 0.119 Yb 0.119 Ta 0.119 Nb 0.119 o 2 ), including ZrO 2 , Y 2 o 3 , Yb 2 o 3 、 Ta 2 o 5 , Nb 2 o 5The oxide powders were placed in different alumina crucibles, put into a box-type muffle furnace and kept at 1000 °C for 3 h, and the heating rate and cooling rate were controlled at 8 °C / min to remove the adsorbed water and Impurities.

[0051] Pour the calcined oxide powders into a high-energy ball mill tank, add a certain amount of isopropanol (90ml) and zirconia balls (0.3mm, the ball-to-material ratio is 8:1), and perform high-energy ball milling. The rotating speed is 2700r / min, and the ball milling time is 8h.

[0052] The suspension after the high-energy ball milling is separated from the ball material, washed with isopropanol for 5 times, and the obtained mixed suspension ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com