Connecting structure of stiff tubular column and reinforced concrete beam column

A reinforced concrete and beam-to-column connection technology, applied to structural elements, elongated structural members for load-bearing, columns, etc., can solve the problem of difficulty in accurately reserving opening positions, difficulty in ensuring welding quality, and weakening the rigidity of circular pipe columns and other problems, to achieve the effects of easy guarantee of welding quality, low installation difficulty and reduced construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

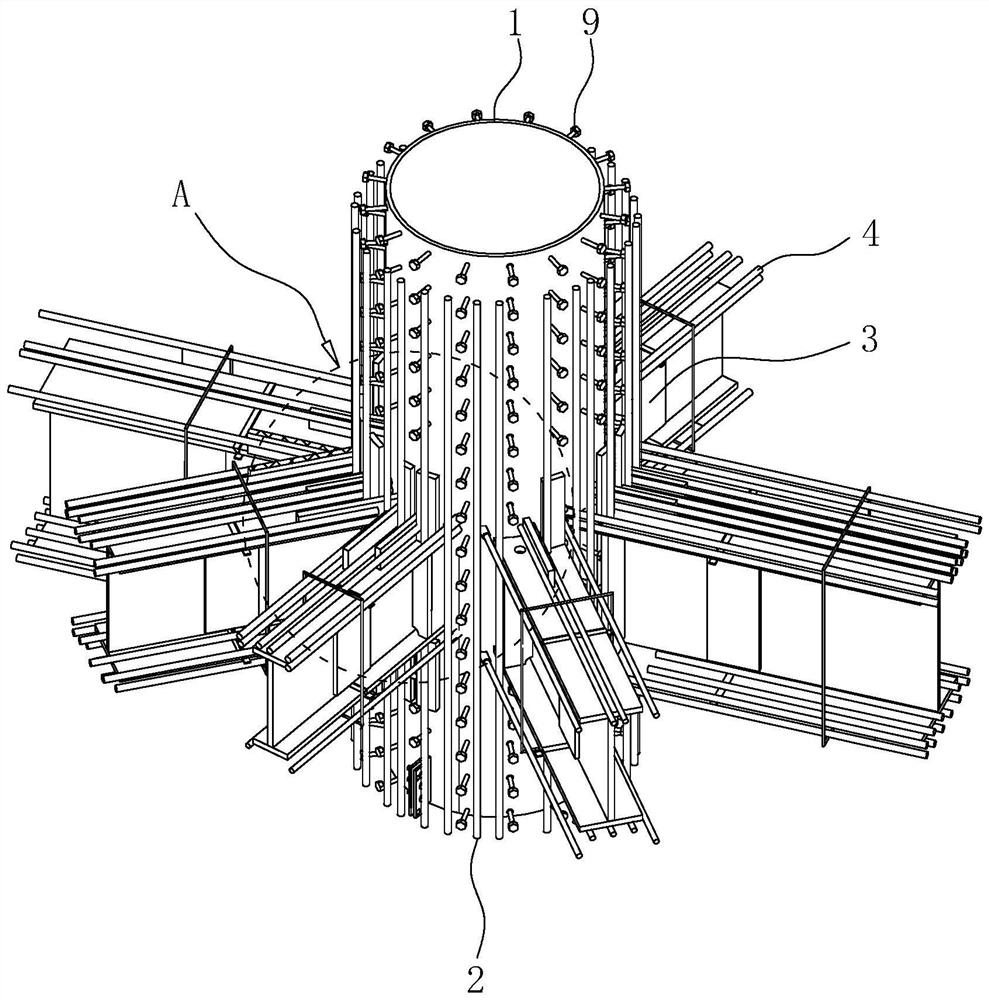

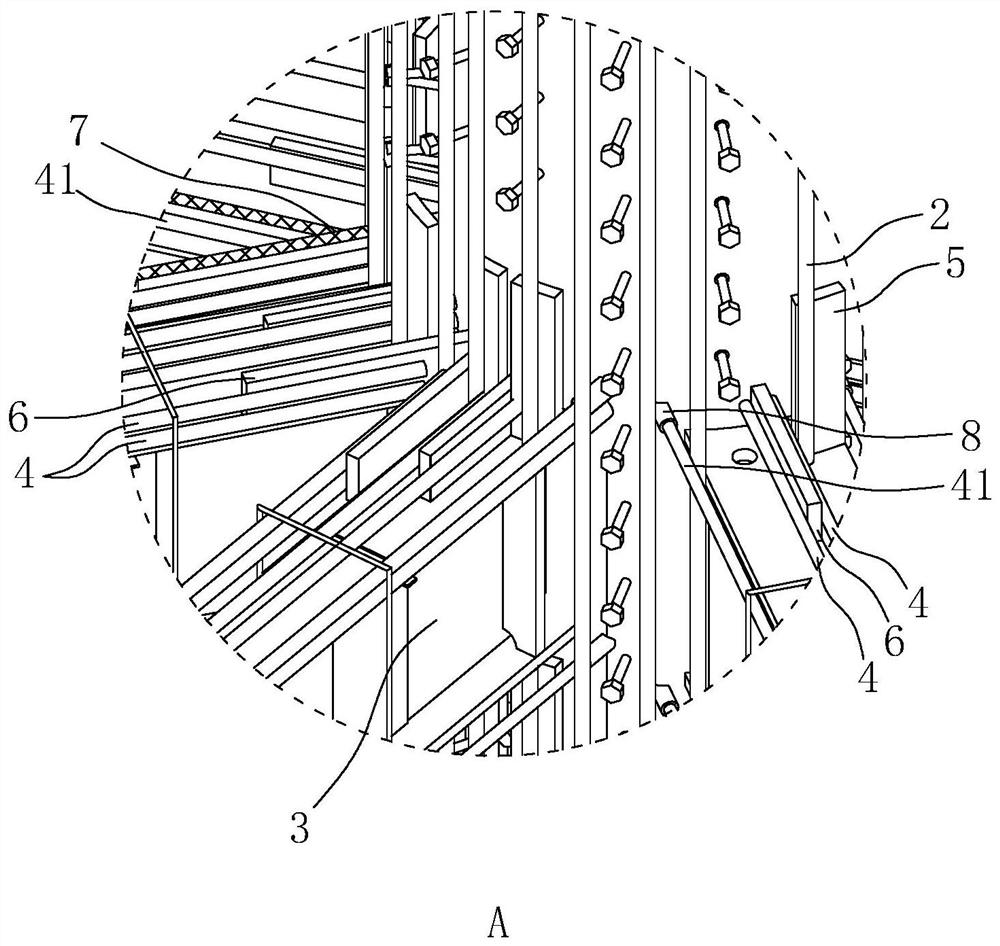

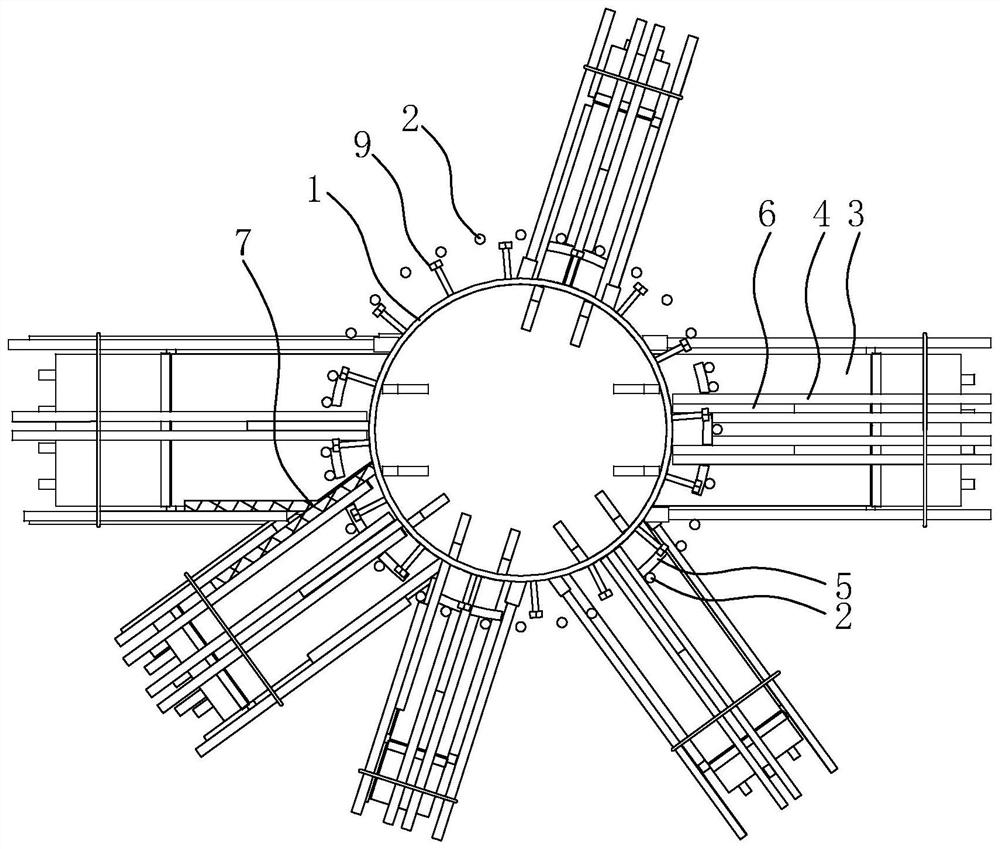

[0033] The following is attached Figure 1-5 The application is described in further detail.

[0034] refer to figure 1 , the embodiment of the present application discloses a connection structure between a rigid circular pipe column and a reinforced concrete beam column, including a vertically arranged circular pipe column 1, a steel corbel 3 fixed on the circular pipe column 1, and a steel corbel 3 fixed on the circular pipe column. 1 and steel bars on steel corbels 3. The circular pipe column 1 is a hollow cylindrical cylinder, and the peripheral side of the circular pipe column 1 is welded with studs 9; the steel corbel 3 is an H-shaped corbel, and the steel corbel 3 is fixed on the peripheral side of the circular pipe column 1 by bolts. A plurality of steel corbels 3 are fixed on the circumference of the circular pipe column 1; the reinforcing bars include a column reinforcement 2 arranged in the axial direction of the circular pipe column 1 and a beam reinforcement 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com