Antibacterial ecological board production and manufacturing quality detection and early warning system based on machine vision

A technology for manufacturing quality and early warning system, applied in the direction of instruments, measuring devices, testing material hardness, etc., can solve the problem that the quality detection accuracy of antibacterial ecological board cannot be effectively improved, the quality early warning efficiency of antibacterial ecological board cannot be effectively improved, and the quality of antibacterial ecological board cannot be effectively improved. To improve the reference of antibacterial ecological board and other issues, to achieve the effect of improving early warning efficiency, improving convenience, and improving scientificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following will be implemented in conjunction with the present invention. The above content is only an example and description of the concept of the present invention. Those skilled in the art will make various modifications or supplements to the described specific embodiments or replace them in similar ways. As long as it does not deviate from the concept of the invention or exceeds the scope defined in the claims, it shall belong to the protection scope of the present invention.

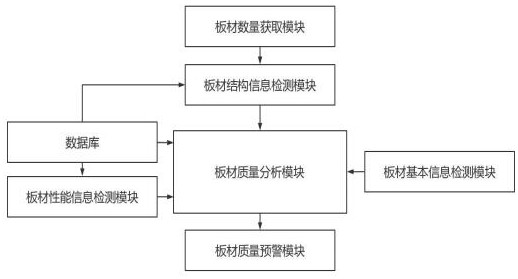

[0051] see figure 1 As shown, a machine vision-based antibacterial eco-board manufacturing quality inspection and early warning system includes a board quantity acquisition module, a board structure information detection module, a board performance information detection module, a board basic information detection module, a board quality analysis module, and a board quality analysis module. Early warning module and database.

[0052] The plate quality analysis module is respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com