Spherically-connected engine fuel injector binding post structure

A technology of fuel injectors and terminal posts, which is applied in the direction of engine components, machines/engines, connections, etc. It can solve the problems of small size, high risk of sliding tooth failure, and easy breakage of bolts, etc., to achieve large contact area, low risk of failure, Reliable effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

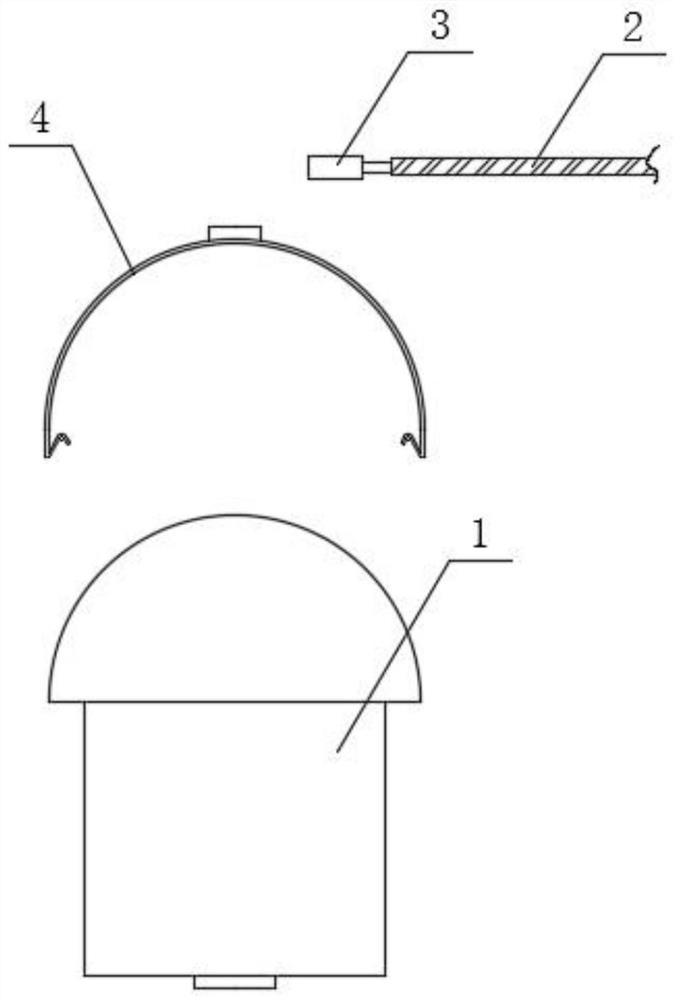

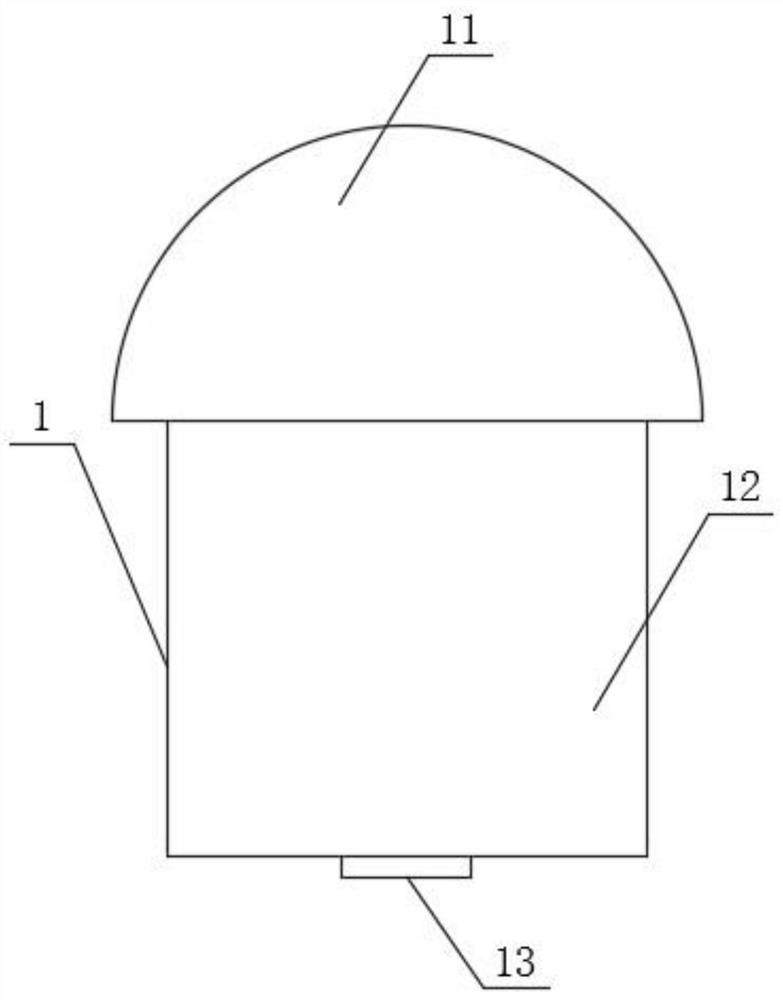

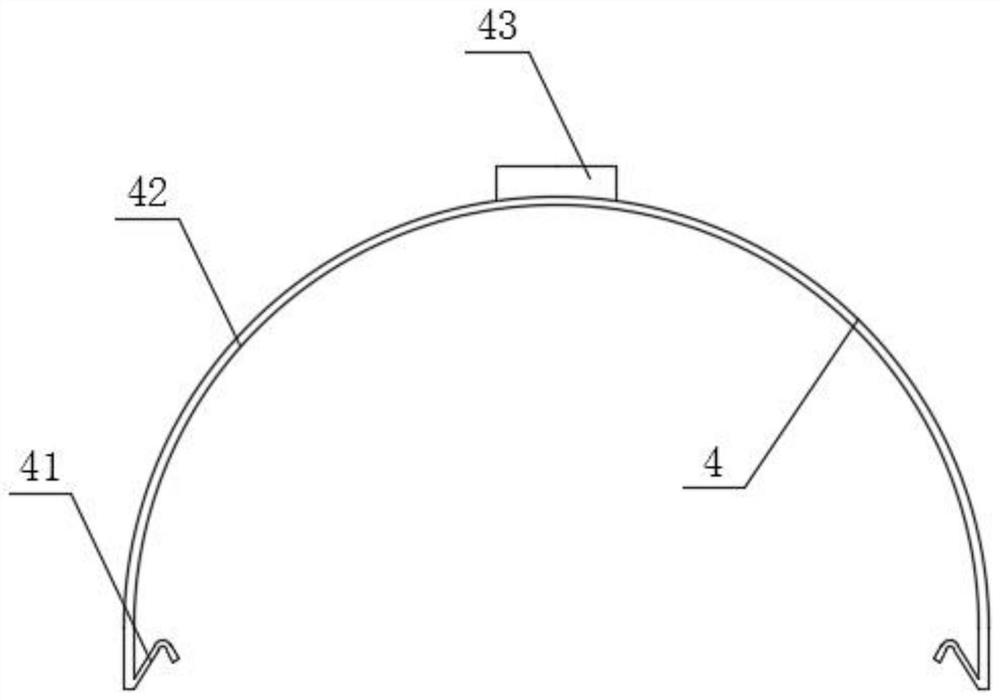

[0024] This embodiment provides: a ball-type connected engine fuel injector terminal structure, including a welding plate main body 3, the welding plate main body 3 is installed on one side of the wire harness 2, the wire harness 2 is a circular tubular structure with a hollow interior, and the wire harness 2 The outer side of the welding plate is provided with a protective cover, and the lower part of the welding plate main body 3 is provided with a spherical wiring cover 4 for the injector harness. A support plate is provided at the intersection of the board main body 3 and the wiring harness 2 , and a fuel injector spherical terminal 1 is provided below the spherical wiring cover 4 of the fuel injector wiring harness.

[0025] By adopting the above technical solutions:

[0026] The spherical terminal 1 of the fuel injector is composed of a hemispherical body 11, a cylinder 12 and a first spot welding plate 13, the first spot welding plate 13 is installed at the lower axis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com