Catalyst for removing methylbenzene as well as preparation and application of catalyst

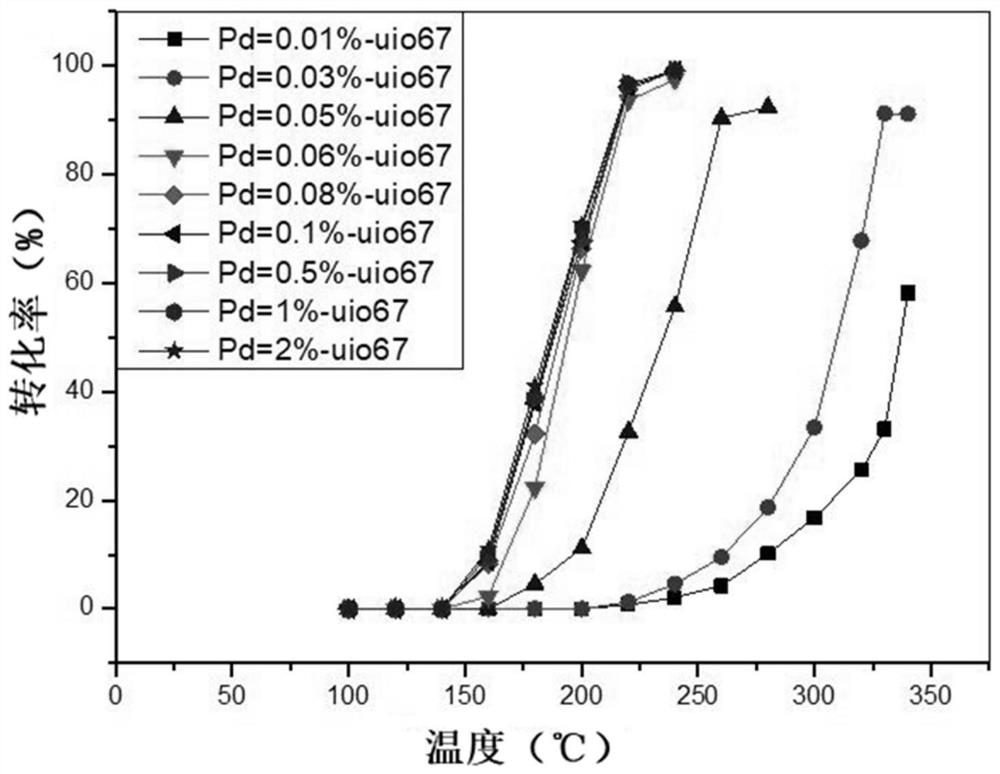

A catalyst and a technology for toluene are applied to the catalyst for removing toluene and the fields of preparation and application thereof, achieving the effects of improving the degree of removal, easy control of preparation conditions, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

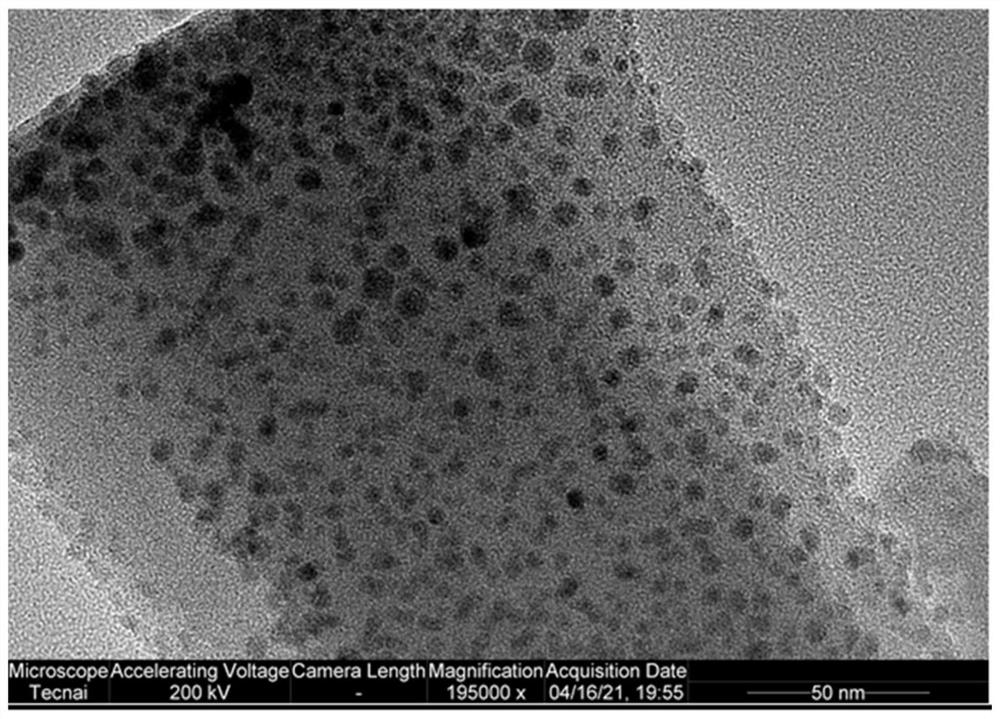

Image

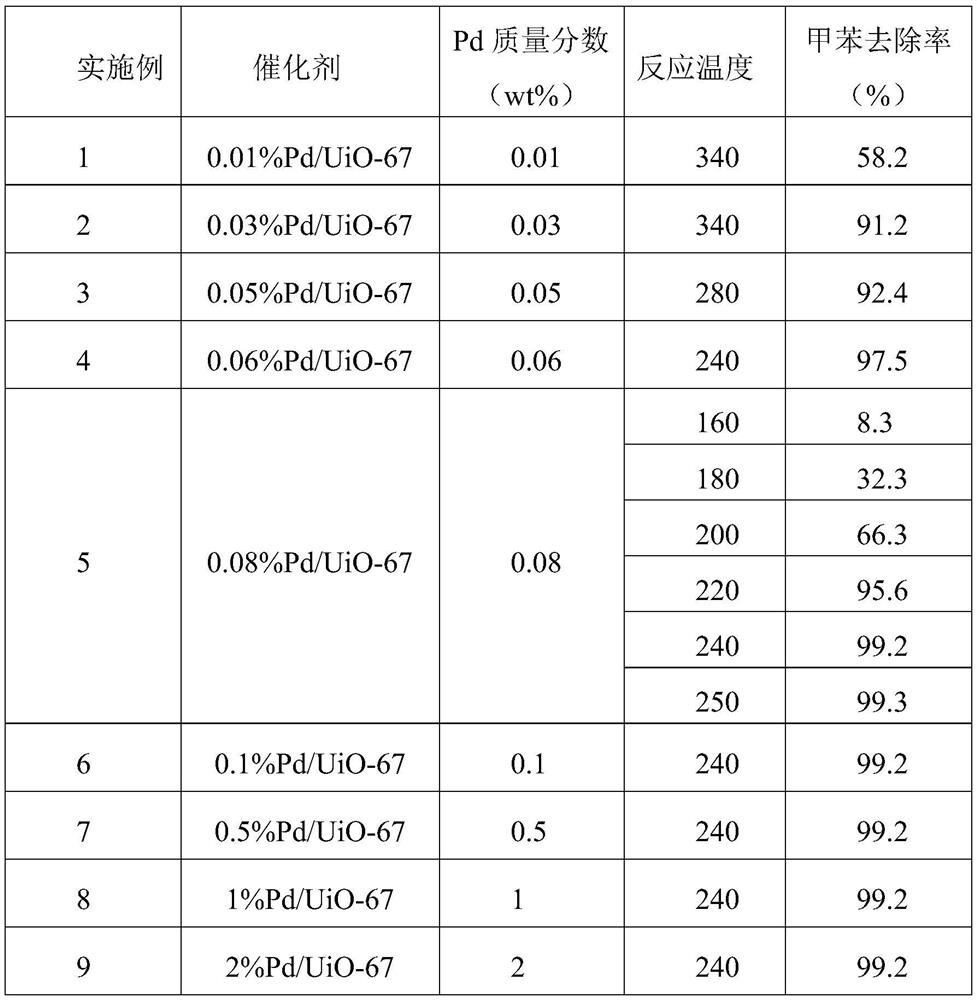

Examples

Embodiment 1

[0045] Measure 100mL from 1g / L citric acid solution, add 1g UiO-67 carrier material to the citric acid solution and stir for 0.5 hours to form the first suspension, the first suspension was left to stand for 6 hours, from 1g / L L PdCl 2 Weigh 0.166mLPdCl in the solution 2 solution, the PdCl 2The solution was slowly added to the first suspension and stirred to form the second suspension, the second suspension was left to stand for 12 hours, filtered 5 times through a suction filter, and then dried in an oven at 120°C to obtain the catalyst Precursors, catalyst precursors are placed in a muffle furnace and roasted at 300°C for 3 hours to obtain catalyst oxides, which are screened at 40-80 meshes for activity evaluation. The prepared catalyst is 0.01% Pd / UiO-67 catalyst, and Pd accounts for the whole in the catalyst 0.01% of catalyst mass.

[0046] The preparation method of UiO-67 comprises the following steps: get 4.66g zirconium tetrachloride, 4.844g biphenyl dicarboxylic aci...

Embodiment 2

[0051] Measure 50mL from 1g / L citric acid solution, add 1g UiO-67 carrier material to the citric acid solution and stir for 0.5 hours to form the first suspension, the first suspension was left standing for 8 hours, from 1g / L L PdCl 2 Weigh 0.498mLPdCl in the solution 2 solution, the PdCl 2 The solution was slowly added to the first suspension and stirred to form the second suspension, and the second suspension was left to stand for 14 hours, filtered through a suction filter for 5 times, and then dried in an oven at 120°C to obtain the catalyst Precursor, catalyst precursor is placed in a muffle furnace and roasted at 300°C for 3 hours to obtain a catalyst oxide, which is screened at 40-80 meshes for activity evaluation. The prepared catalyst is 0.03% Pd / UiO-67 catalyst, and Pd accounts for the whole in the catalyst 0.03% of catalyst mass.

[0052] The preparation method of UiO-67 comprises the following steps: get 4.66g zirconium tetrachloride, 4.844g biphenyl dicarboxyli...

Embodiment 3

[0057] Measure 100mL from a 1g / L citric acid solution, add 1g of UiO-67 carrier material to the citric acid solution and stir for 0.5 hours to form the first suspension, and leave the first suspension for 7 hours, from 1g / L L PdCl 2 Weigh 0.83mLPdCl in the solution 2 solution, the PdCl 2 The solution was slowly added to the first suspension and stirred to form the second suspension, the second suspension was left to stand for 13 hours, filtered 7 times through a suction filter, and then dried in an oven at 120°C to obtain the catalyst Precursor, catalyst precursor is placed in a muffle furnace and roasted at 300°C for 3 hours to obtain a catalyst oxide, which is screened at 40-80 meshes for activity evaluation. The prepared catalyst is 0.05% Pd / UiO-67 catalyst, and Pd accounts for the whole in the catalyst 0.05% of catalyst mass.

[0058] The preparation method of UiO-67 comprises the following steps: get 4.66g zirconium tetrachloride, 4.844g biphenyl dicarboxylic acid, joi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com