Three-roller type roundness correction method and roundness correction device for pipe end of large pipe fitting

A three-roller, pipe-end technology, applied in the field of mechanical processing, can solve the problems of no overall rounding method, low efficiency of rounding rounding, high cost, etc., and achieve the effect of wide rounding range, low cost, continuous loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

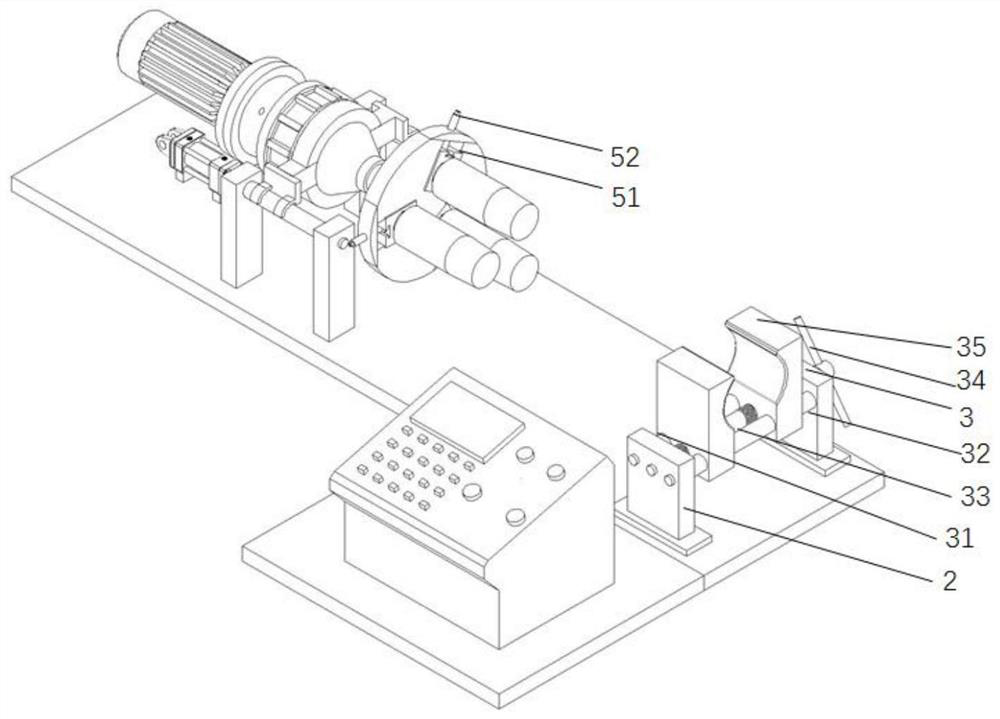

[0043] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

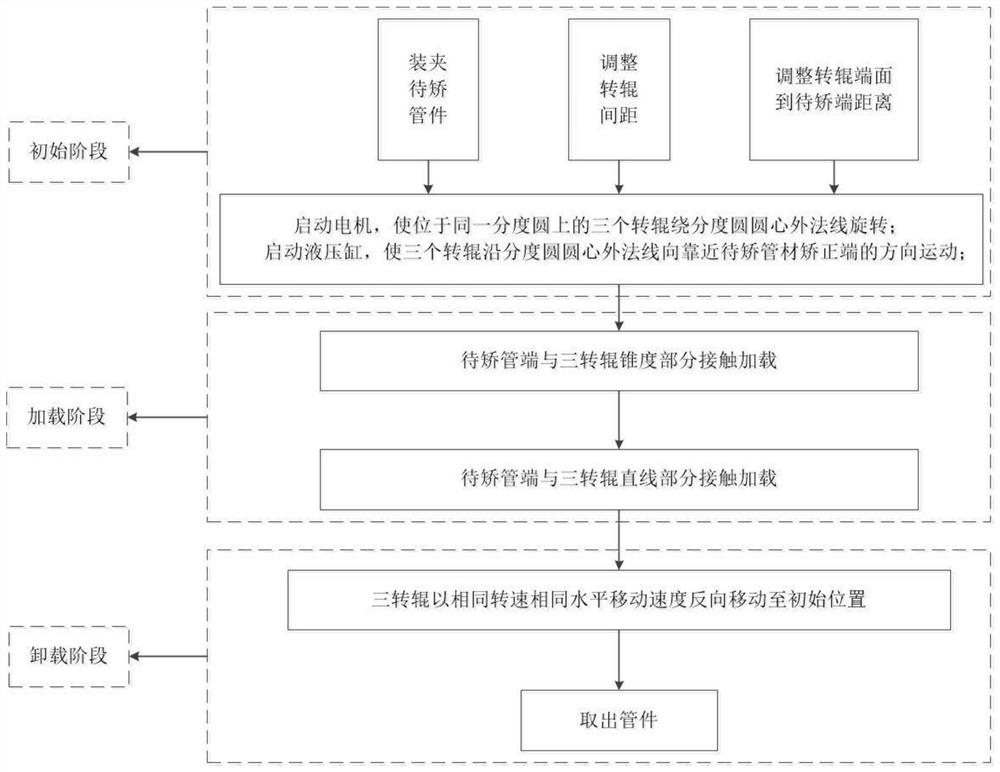

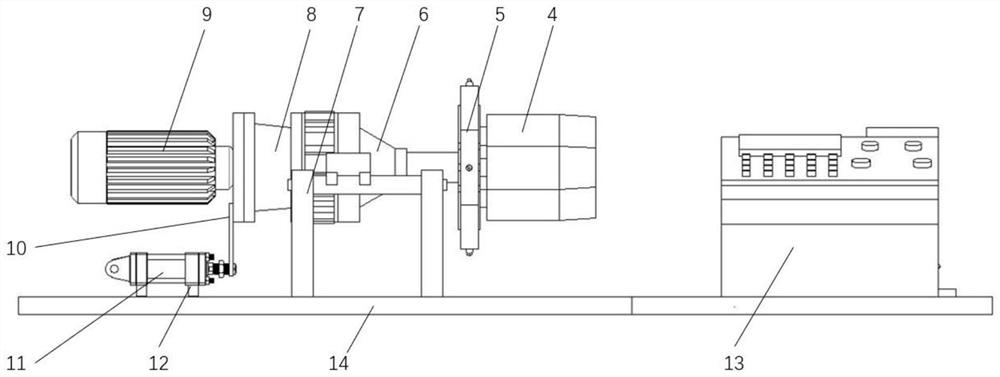

[0044] Three-roll rounding method for pipe ends of large pipe fittings, such as figure 1 As shown, the pipe to be straightened 1 is fixed in the clamping assembly 3, the distance between the three-turn roller 4 and the tapered end of the three-turn roller 4 and the end of the pipe to be straightened is adjusted, and the rotating drive assembly drives the three-turn roller 4 to rotate, The displacement drive assembly drives the rotating roller 4 to move towards the straightened end of the pipe to be straightened 1. When the rotating roller 4 contacts the straightened end of the pipe to be straightened 1, it starts to load, and the cross section of the pipe to be straightened 1 undergoes elastic-plastic deformation. During the gradual contact of the pipe fitting 1, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com