Plasma arc welding machine

A plasma arc and welding machine technology, applied in the field of metal welding, can solve the problems of reducing the connection between the metal and the welding connection block, debris easily falling on the welding position, affecting the welding efficiency, etc., so as to avoid repeated welding or omission, reduce Welding is not tight and reduces labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

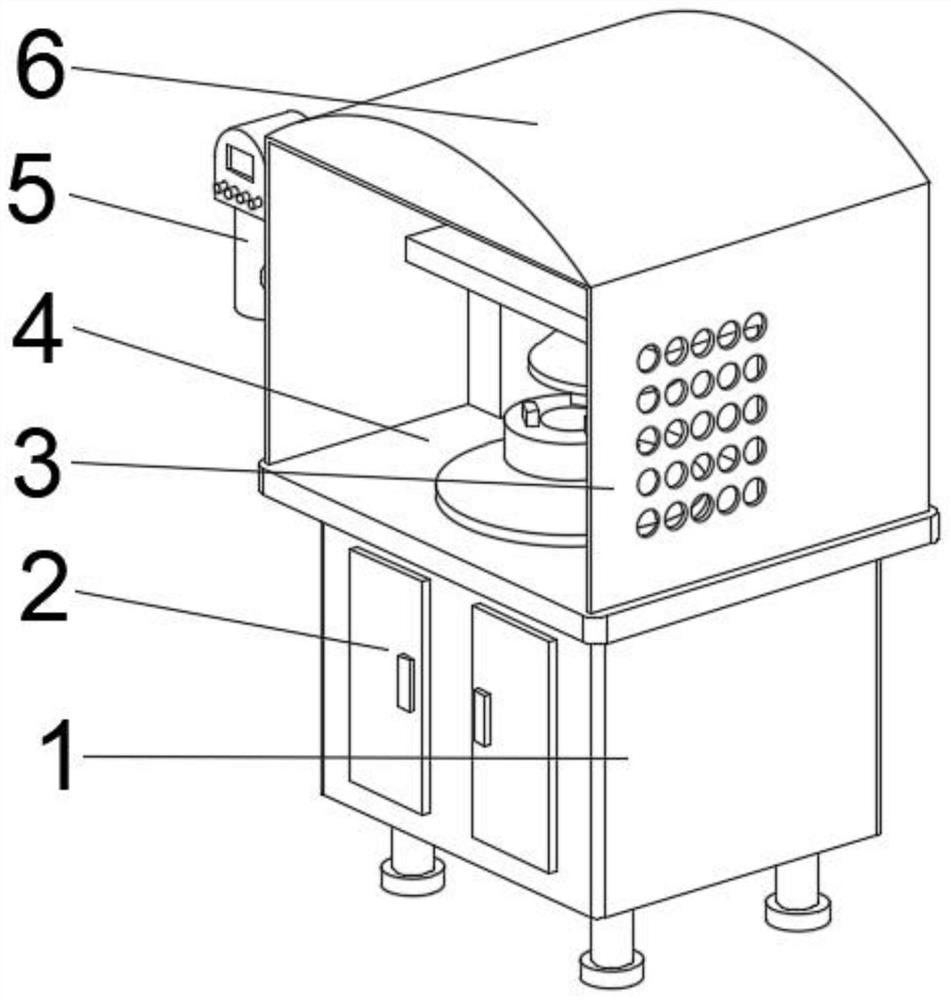

[0033] see Figure 1-2 , the present invention provides a technical solution: a plasma arc welding machine, comprising a main body box 1, maintenance box doors 2 are arranged on both sides of the front middle part of the main body box 1, and a welding device 4 is fixedly connected to the top of the main body box 1, and the welding device Both sides of the top of 4 are fixedly connected with protective plate 3, the middle part of the right outer wall of protective plate 3 is fixedly connected with controller 5, and the top of protective plate 3 is fixedly connected with collection box 6.

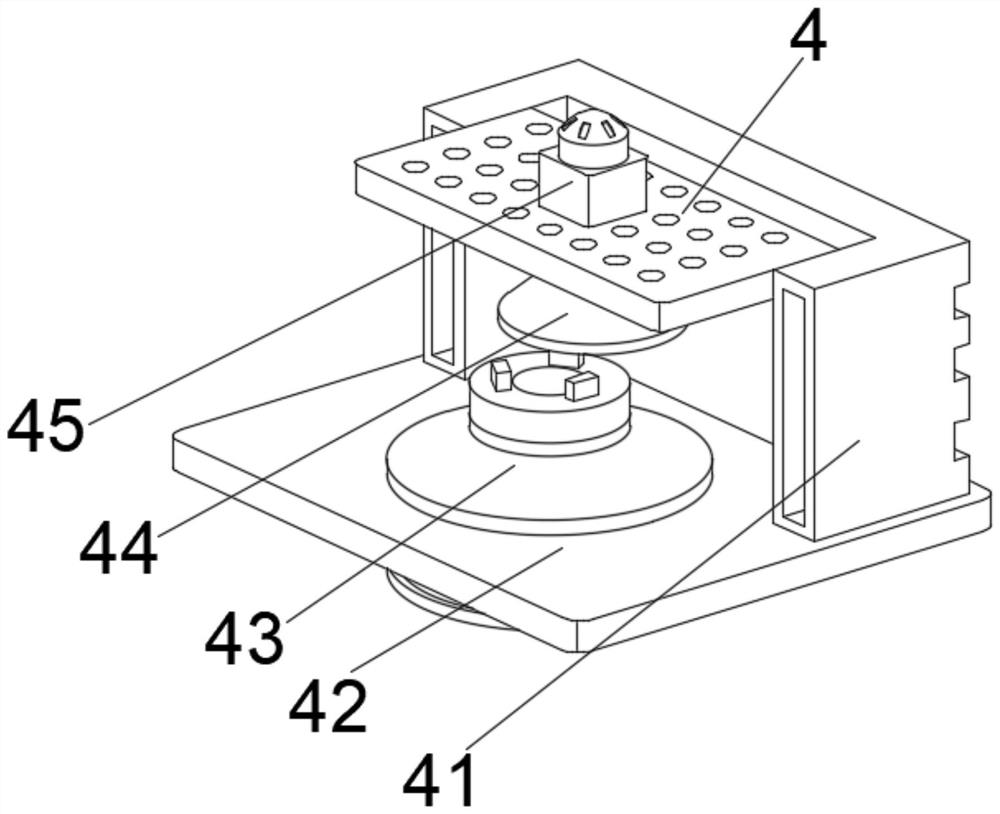

[0034] Wherein, welding device 4 comprises working platform 42, and the top middle position of working platform 42 is provided with fastening mechanism 43, and the top of working platform 42 is positioned at the both sides of fastening mechanism 43 and is fixedly connected with support frame 41, and the top center of support frame 41 A plasma welder 45 is provided at the position, and the bot...

Embodiment 2

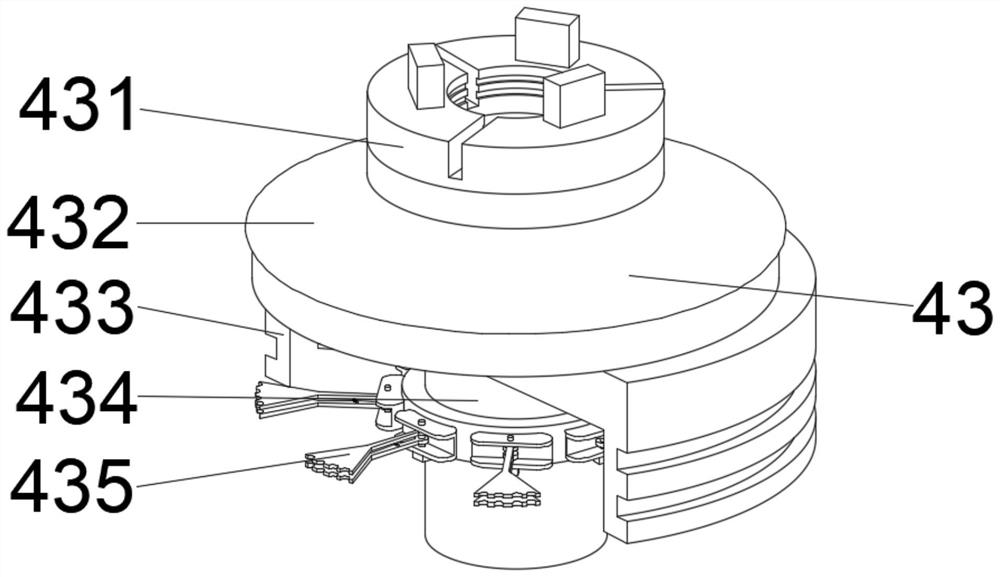

[0037] see Figure 1-4 On the basis of Embodiment 1, the present invention provides a technical solution: component 1 of the fastening mechanism 43 includes a connecting shell 433, the top of the connecting shell 433 is fixedly connected with a stabilizing block 432, and the top middle position of the stabilizing block 432 is provided with For the fastener 431 , a guide post 434 is provided at the middle of the inner cavity top of the connection shell 433 , and a positioning fastening body 435 is provided at the middle outer surface of the guide post 434 .

[0038] Wherein, the first component of the protection mechanism 44 includes a protective case 441, the top of the protective case 441 is fixedly connected with a connector 443, the middle part of the outer wall on both sides of the protective case 441 is fixedly connected with a fixing seat 445, and the bottom of the inner wall on both sides of the protective case 441 is provided with The transition ring 442 and the middle...

Embodiment 3

[0041] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the second component of the fastening mechanism 43 includes a rotating part d2, the top of the rotating part d2 is provided with a contact body d1, and the inner cavity of the rotating part d2 There is a rubber guide piece d3 in the middle of the top, positioning columns d5 are fixedly connected to both sides of the front of the rotating piece d2, and a friction increasing block d4 is arranged in the middle of the back of the rotating piece d2, and the front of the friction increasing piece d4 runs through the rotating piece d2 and extends to The inside of the rotating part d2.

[0042] Among them, the second component of the protection mechanism 44 includes a fixed connector t1, the top of the inner wall on both sides of the fixed connector t1 is fixedly connected with the limit block t2, and the middle part of the outer wall on both sides of the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com