Method for identifying misalignment fault of angle cock handle of railway wagon

A technology for knuckle cocks and railway wagons, applied to railway car body parts, railway signals, neural learning methods, etc., can solve the problem of low accuracy of knuckle cock handles, achieve accurate pixel information of key points, and improve Accuracy, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

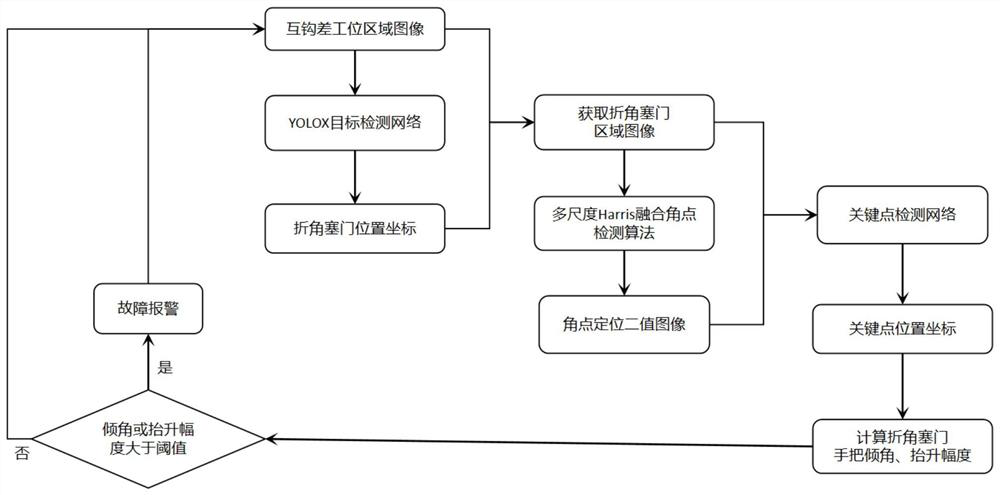

[0057] Specific implementation mode 1. Combination figure 1 and figure 2 This embodiment will be described. In this embodiment, a method for identifying a failure of a railway wagon knuckle cock handle not in the correct position, the method is specifically implemented through the following steps:

[0058] Step 1, obtaining the side image of the railway freight car, and intercepting the image of the inter-hook difference station area from the obtained image;

[0059] Step 2. Input the image of the inter-hook difference station area intercepted in step 1 into the YOLOX target detection network, and use the YOLOX target detection network to predict the pixel coordinate information of the bounding box of the knuckle plug part in the inter-hook difference station area image, and then Using the predicted pixel coordinate information, cut out the image of the knuckle plug part area from the input inter-hook difference station area image;

[0060] Step 3, extracting the corner fe...

specific Embodiment approach 2

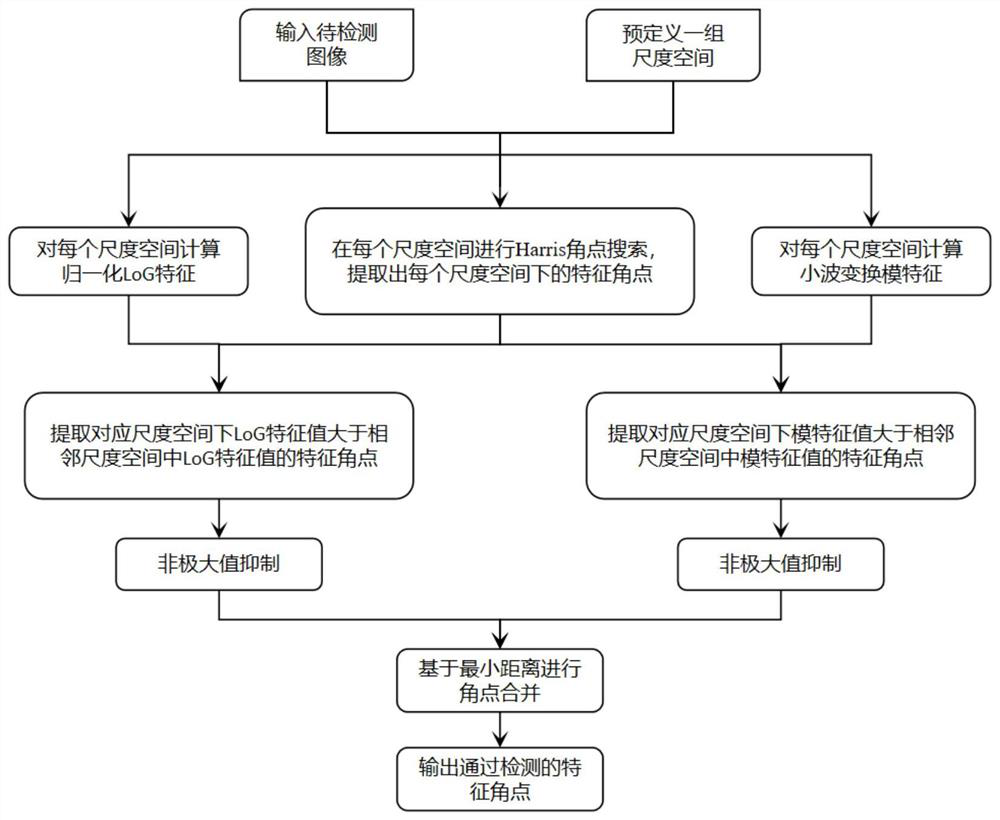

[0066] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is: the specific process of step three is:

[0067] Step 31. Based on the Gaussian scale space theory, use parameters of different scales to construct the Gaussian filter kernel (the specific scale can be set manually according to the needs), and then build a multi-scale based on the Gaussian filter kernel and the cropped corner plug part area image space image;

[0068] Before performing step 31, it is also possible to perform contrast enhancement on the cropped corner plug part area image, and then establish a multi-scale spatial image based on the contrast-enhanced image;

[0069] Step 32. For the spatial image of each scale, use the Harris corner detection algorithm to find the corners of the image, and record the set of corners of the spatial images of each scale as the initial candidate corner set P;

[0070] Step 33, for the spatial image of eac...

specific Embodiment approach 3

[0077] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the corner point positioning binary image is generated based on the corner points in the final corner point set F, which is specifically:

[0078] For any pixel in the obtained corner cock part area image, if the Manhattan distance between the pixel and at least one corner point in the final corner point set F is less than or equal to the threshold b (the value of the threshold b is artificially set according to the actual image size set), then set the pixel value of the pixel point to 255, otherwise, set the pixel value of the pixel point to 0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com