Atomic gas chamber non-magnetic transparent electric heating film preparation method based on laser direct writing

A laser direct writing, atomic gas chamber technology, applied in ohmic resistance heating, electric heating devices, heating element materials, etc., can solve the problems of temperature control accuracy and uneven heating, limited temperature control accuracy, limited heating power, etc. And the magnetic field control is accurate and controllable, meets the requirements of non-magnetization, and has excellent working effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

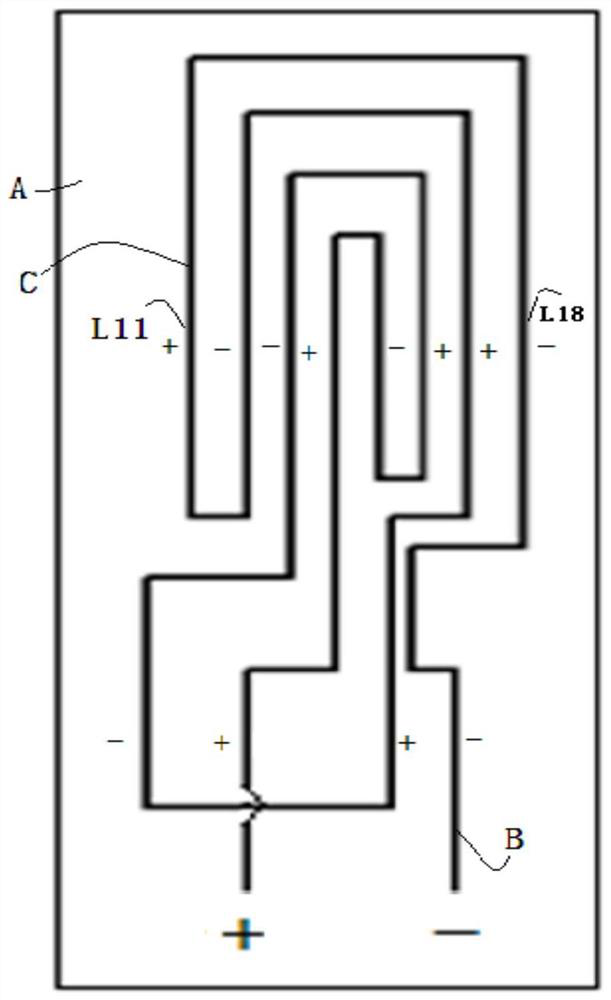

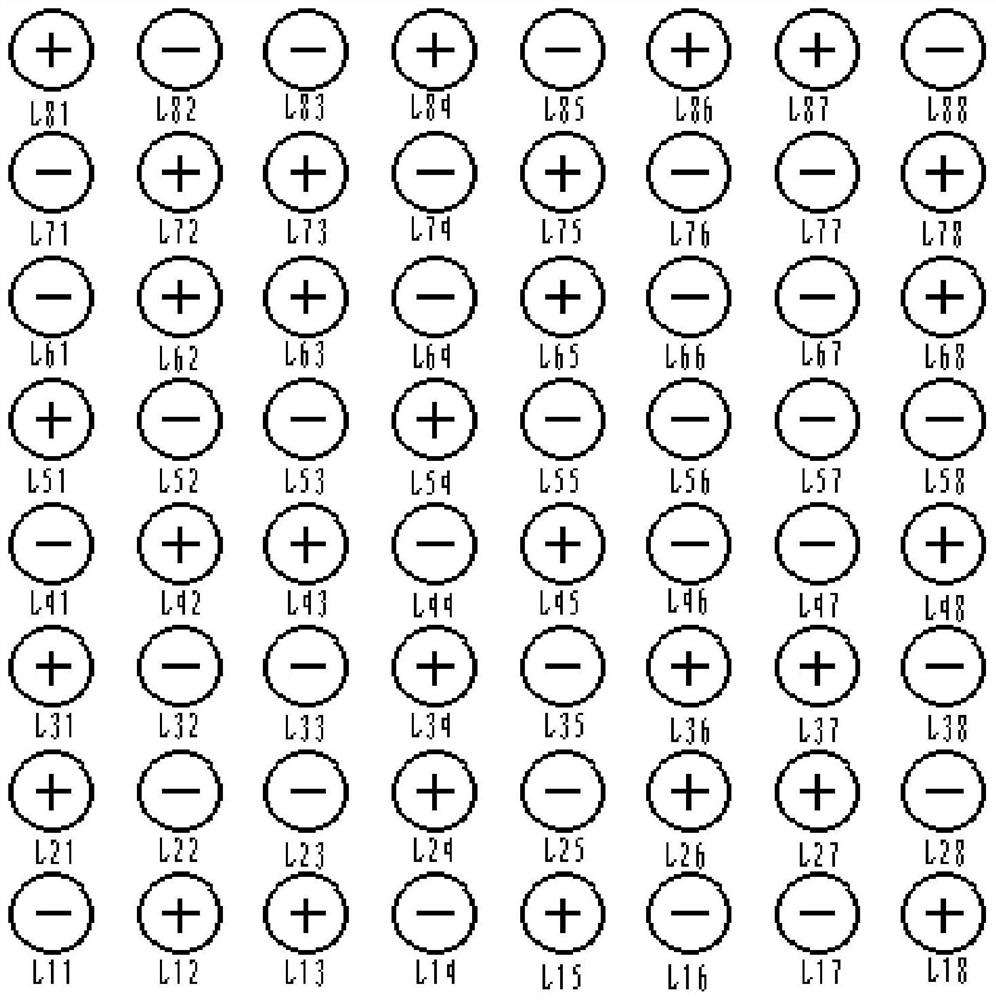

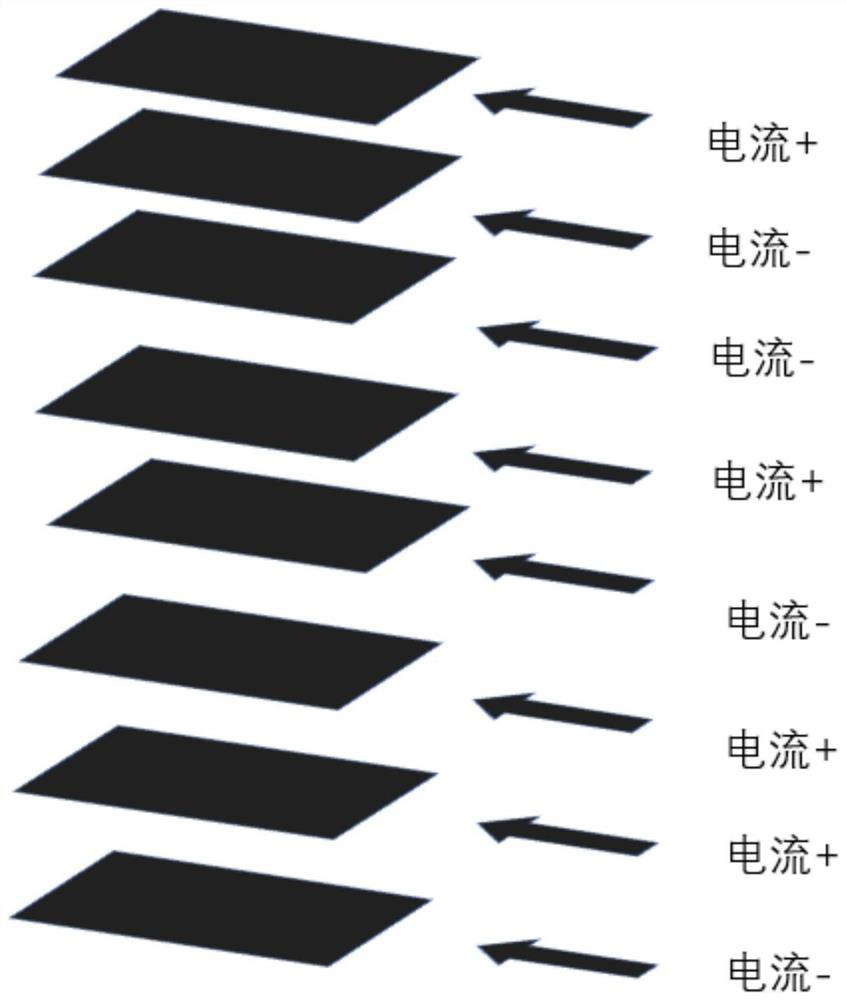

[0018] Below with the accompanying drawings ( Figure 1-Figure 3 ) and Examples illustrate the present invention.

[0019] figure 1 It is a schematic diagram of a micropattern with an octopole configuration produced by implementing a laser direct writing-based atomic air chamber non-magnetic transparent electric heating film preparation method of the present invention. figure 2 so figure 1 It is a schematic diagram of the current direction configuration of each graphene wire in the eight-layer GO film based on the eight-layer GO film. image 3 It is a schematic diagram of an 8-layer GO thin film made by implementing a laser direct writing-based atomic gas chamber non-magnetic transparent electric heating film preparation method of the present invention. refer to Figure 1 to Figure 3 As shown, a laser direct writing-based atomic air chamber non-magnetic transparent electric heating film preparation method uses laser direct writing reduction technology to produce line-type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com