Cushion packaging material and preparation method thereof

A packaging material and paste technology, applied in the field of packaging materials, can solve the problems of poor waterproof performance, inability to apply cushioning packaging materials and cold chain insulation cushioning packaging materials, high material costs, etc., to achieve good waterproof performance, good market application prospects, The effect of easy processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

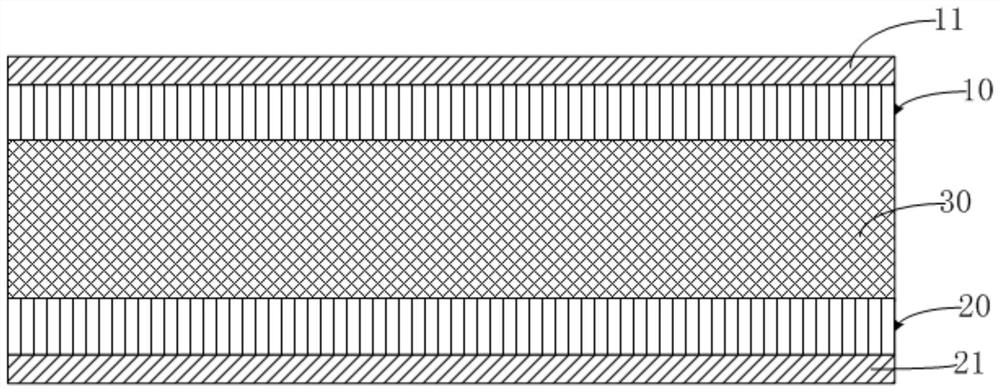

[0057] Such as figure 1 Shown is a schematic cross-sectional view of the packaging material in Example 1 of the present invention.

[0058] The packaging material in Example 1 of the present invention has a multi-layer composite structure, which includes a first paper base material 10 and a second paper base material 20 arranged up and down oppositely, and The foam layer 30 in between.

[0059] Specifically in this embodiment, the opposite outer surfaces of the first paper substrate 10 and the second paper substrate 20 are each coated with a waterproof coating; specifically, the outer surfaces of the first paper substrate 10 ( figure 1 The upper side shown) is coated with a layer of waterproof coating 11, and the outer side of the second paper substrate 20 ( figure 1 The lower side shown) is coated with a waterproof coating 21.

[0060] In a specific embodiment of the present application, both the first paper base material 10 and the second paper base material 20 are made o...

Embodiment 2

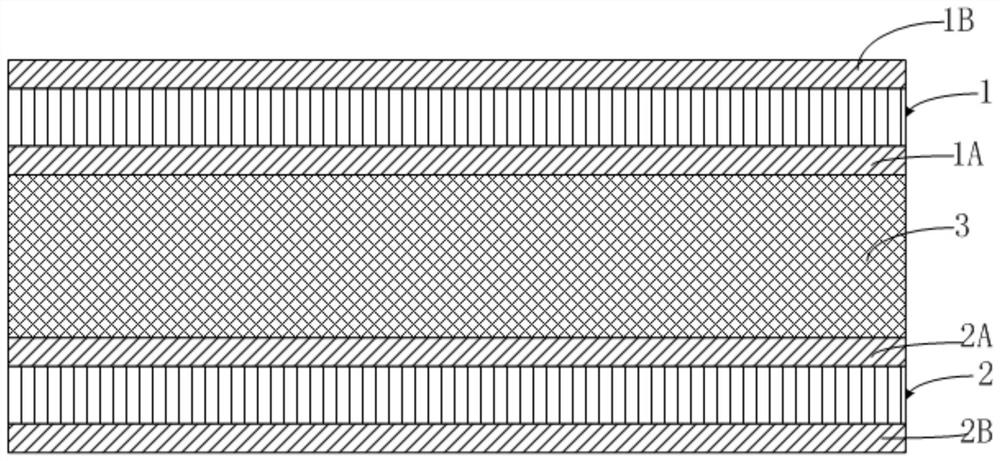

[0084] Such as figure 2 Shown is a schematic cross-sectional view of the packaging material of Example 2 of the present invention.

[0085] The packaging material of Example 2 of the present invention has a multilayer composite structure, which includes a first paper base material 1 and a second paper base material 2 arranged up and down oppositely, and Foam layer 3 in between.

[0086] Specifically in this embodiment, the inner and outer surfaces of the first paper substrate 1 are coated with a layer of waterproof coating 1A and 1B, and the inner and outer surfaces of the second paper substrate 2 are also coated with a layer of waterproof coating. Coat 2A and 2B.

[0087] In this embodiment, the foam layer 3 is formed by coating between the first paper substrate 1 (waterproof coating 1A) and the second paper substrate 2 (waterproof coating 2A) (specifically, full-screen coating is used). way) a layer of water-based foamable coating, which is obtained by foaming at a tempe...

Embodiment 3

[0103] The only difference between the packaging material of Example 3 and Example 1 is that the foam layer 30 is coated with a water-based foamable coating in a local spot-coating manner between the first paper substrate 10 and the second paper substrate 20. , and obtained by foaming at a temperature of 80-130°C, drying and curing.

[0104] Preferably, in this embodiment, the water-based foamable paint is uniformly applied at intervals of certain rows and columns, and finally foamed, dried and cured to form a foamed layer. The structure of the foam layer is similar to the "bubble film" structure on the market (bubbles are evenly arranged in a certain row and column interval), and the volume of each foam formed is about 0.35-0.4cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com