Mine gas extraction equipment and data management and visualization system and method

A technology of gas drainage and data management, applied in mining equipment, gas discharge, mining equipment, etc., can solve the problems of equipment detection that cannot be observed in real time, hidden dangers of mine safety production, etc., so as to facilitate the management of underground personnel and protect life and property The effect of safety and loss rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Mine Gas Drainage Equipment and Data Management Visualization System

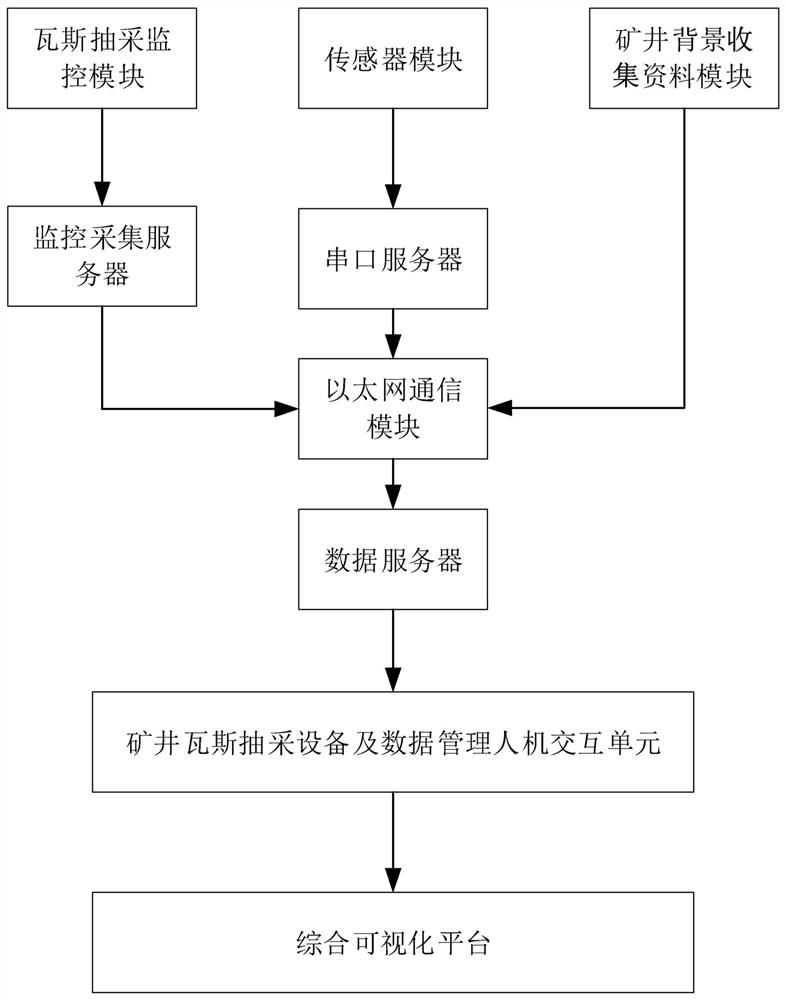

[0050] like figure 1As shown, this embodiment includes a data server, a comprehensive visualization platform, mine gas drainage equipment and data management human-computer interaction unit, gas drainage monitoring module, sensor module, mine background data collection module, Ethernet communication module, serial port server and Monitor collection server.

[0051] The sensor module includes a number of temperature sensors, a number of gas concentration sensors, and a number of gas pressure sensors; the output terminals of the temperature sensors, gas concentration sensors, and gas pressure sensors are connected through RS232 bus or RS485 bus or CAN bus or I 2 The C bus is respectively connected to the input terminals of the serial port server for communication.

[0052] The output end of the serial port server is connected with the input end of the data server through the Ethernet commun...

Embodiment 2

[0060] Example 2 Mine Gas Drainage Equipment and Data Management Visualization Method

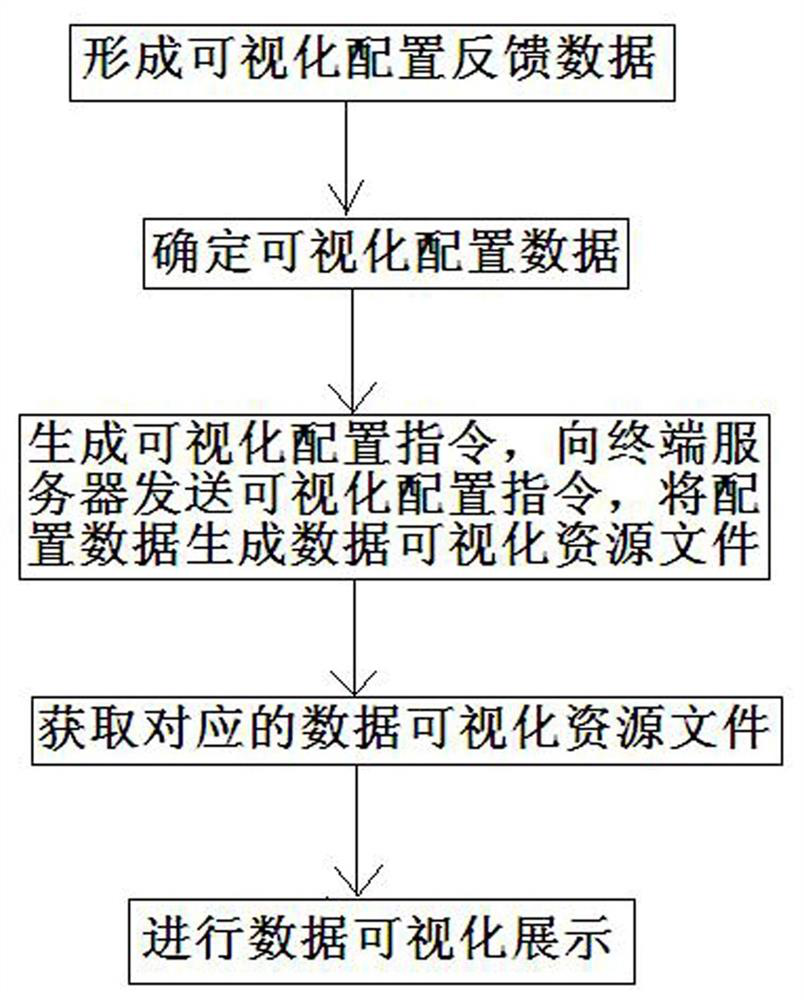

[0061] This embodiment adopts embodiment 1 to realize, such as figure 2 As shown, the method includes the following steps:

[0062] S1. Form visual configuration feedback data

[0063] In this step, on the one hand, the real-time detection data collected by the hardware device is uploaded to the data server, and on the other hand, the user inputs the recorded data into the data server; the data server stores the two aspects of data in its built-in database to form visual configuration feedback data ;

[0064] Specifically, it includes the following simultaneous collection / entry processes,

[0065] ① The camera captures the working status, start and stop status of the mine gas drainage equipment in real time, and sends the results to the data server;

[0066] ②The temperature sensor detects the ambient temperature of the air inlet and return airways and the operating temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com