Cooling device for alloy material production

A technology of cooling device and alloy material, which is applied in the direction of furnace material, charging treatment type, lighting and heating equipment, etc., and can solve the problems of impurity precipitation, pipeline blockage, cooling effect decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

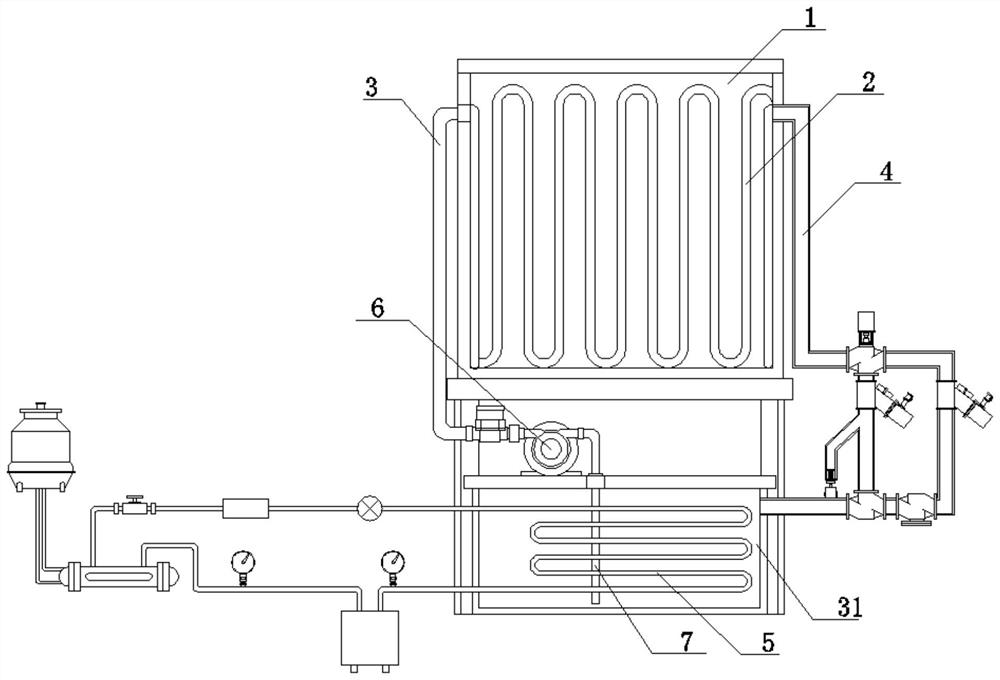

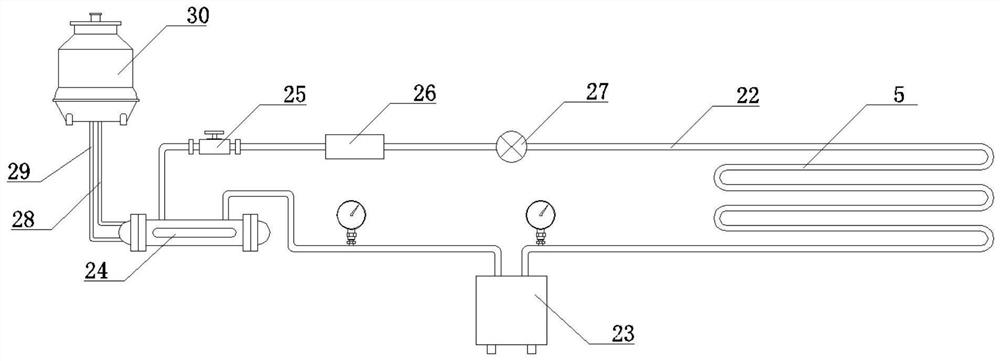

[0039] A cooling device for the production of alloy materials, comprising a furnace 1, the interior of the furnace 1 is provided with a water cooling wall 2, the water cooling wall 2 is connected with a water inlet pipe 3 and a water outlet pipe 4, one end of the water inlet pipe 3 is connected with a water cooling box 31, and the water outlet pipe One end of 4 is connected to the water-cooled box 31, the outlet pipe 4 is connected with a filter module, and the water-cooled box 31 is provided with an evaporating pipe 5 inside, and the evaporating pipe 5 is connected with a cooling module; The water inlet of the pump 6 is connected with a water suction pipe 7 , and the water suction pipe 7 is located inside the water cooling box 31 .

[0040] (see figure 1 )

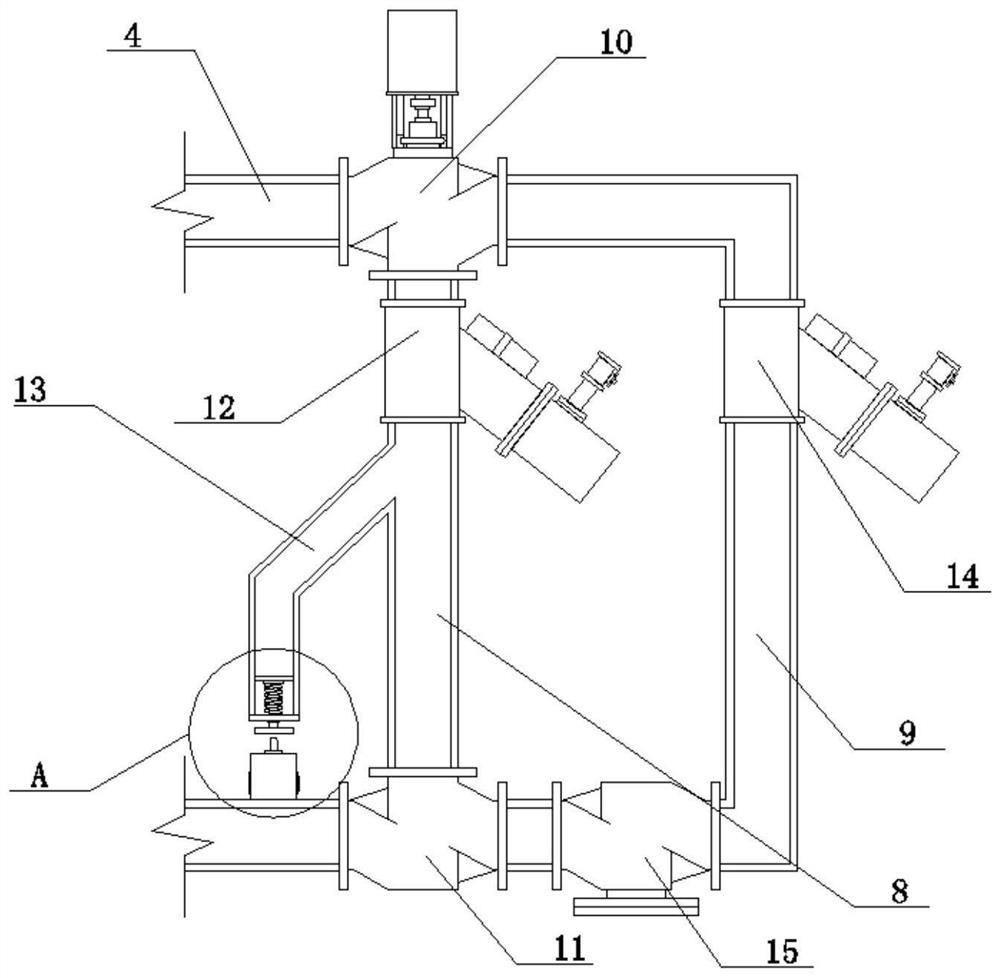

[0041]The filter module includes a working filter tube 8 and a spare filter tube 9. One end of the working filter tube 8 is connected to the outlet pipe 4, the other end of the working filter tube 8 is connected to an el...

specific Embodiment approach

[0046] 1. A smelting barrel is set in the furnace 1, and the smelting barrel is located between the water walls 2;

[0047] Two, the melting furnace 1 starts the circulating pump 6 after the smelting is finished, and the circulating pump 6 extracts the coolant in the water-cooled tank 31 through the suction pipe 7, and imports it into the water-cooled wall 2 through the water inlet pipe 3 to cool the smelting barrel;

[0048] 3. After passing through the water wall 2, the coolant passes through the outlet pipe 4 and is introduced into the working filter pipe 8 by the electric three-way valve 10. The working filter 12 filters the coolant, and at the same time, part of the coolant enters the guide pipe 13, and the fluid of the coolant The pressure makes the piston plate 19 drive the compression spring 21 to press down, and the piston plate 19 drives the push plate 20 to descend through the slide rod 18 to trigger the travel switch 17, and the travel switch 17 controls the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com