Four-mode dielectric waveguide filter

A dielectric waveguide and filter technology, applied in the field of four-mode dielectric waveguide filter, can solve the problems of waste mode, no polarization degeneracy, large thickness of dielectric block, etc., and achieve the effect of reducing the number of cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

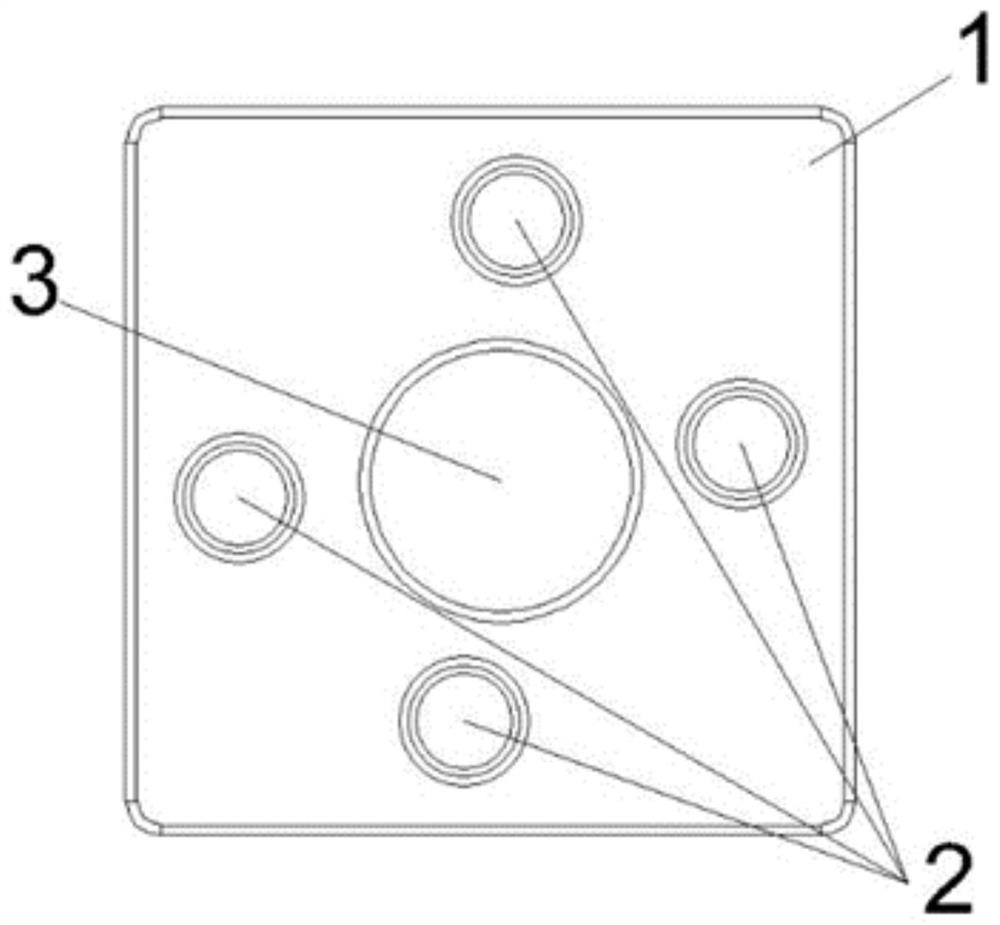

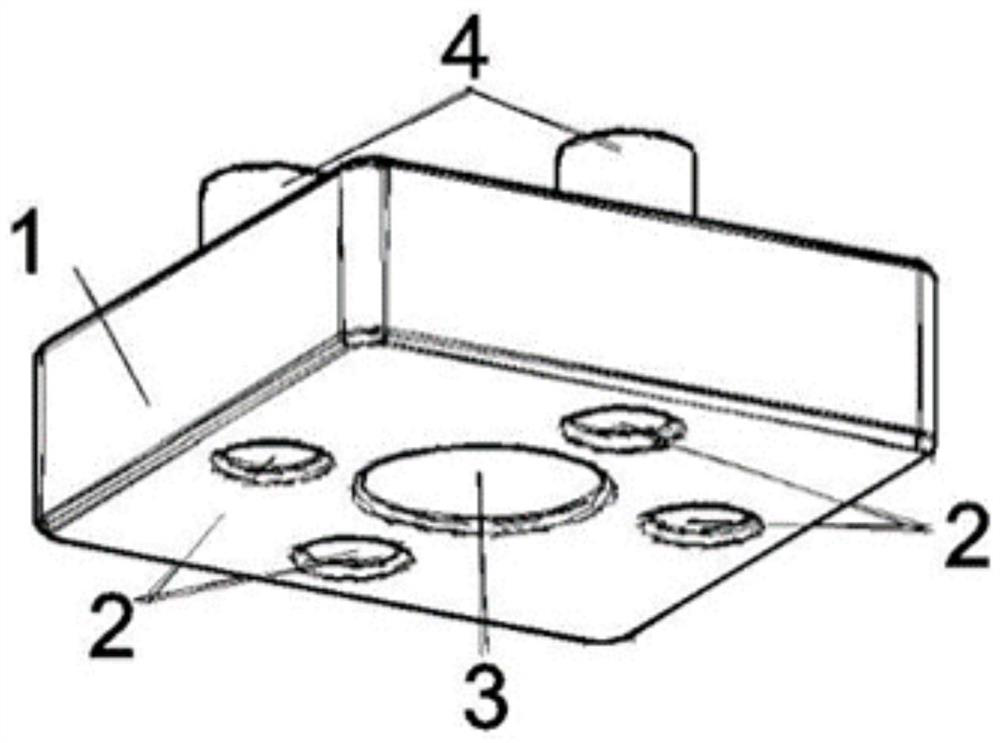

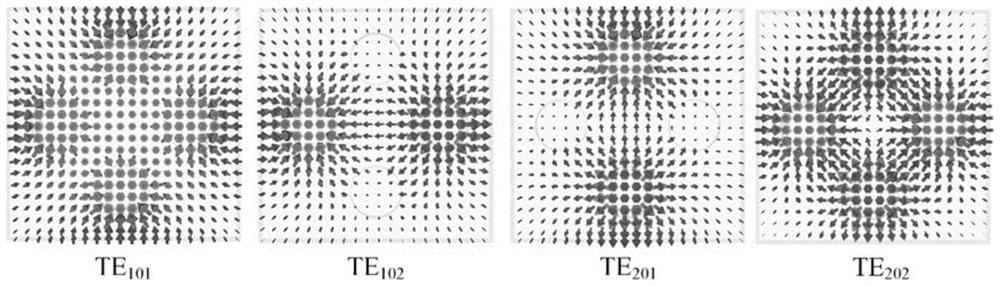

[0022] see figure 1 and figure 2 As shown, this embodiment provides a single-cavity four-mode dielectric waveguide filter, including a silver-plated ceramic dielectric body 1 (in a rectangular shape), the bottom of the dielectric body 1 is connected to a coaxial connector 4, and the coaxial connection The filter 4 is used as the input and output ports to feed the filter, and the embedded depth of the coaxial inner conductor determines the external quality factor of the input and output ports, and determines the electromagnetic field energy entering the filter. The entire dielectric body 1 is formed with only one resonant cavity, and a four-mode structure is set on the top of the resonant cavity. The four-mode structure includes four tuning blind holes 2 and a coupling through hole 3 for adjusting coupling, and two tuning blind holes 2 are located in the Near the transverse centerline of the cavity, the other two tuning blind holes 2 are located near the longitudinal centerli...

Embodiment 2

[0027] Different from Embodiment 1, what this embodiment provides is a multi-cavity four-mode dielectric waveguide filter (not shown in the figure), and coupling through holes are arranged between adjacent resonant cavities of the filter to introduce magnetic coupling, Electric coupling is introduced by setting coupling blind holes; among them, the resonant cavity without four-mode structure can be equipped with a single tuning blind hole at the top or bottom of the cavity to adjust the frequency of the single mode, or without tuning blind holes, by changing The length, width and height of the cavity are used to change the resonant frequency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com